Description

Jiangsu Liangyi is professional manufacturer of AMS 5754 open die forging parts and seamless rolled steel forged rings from china

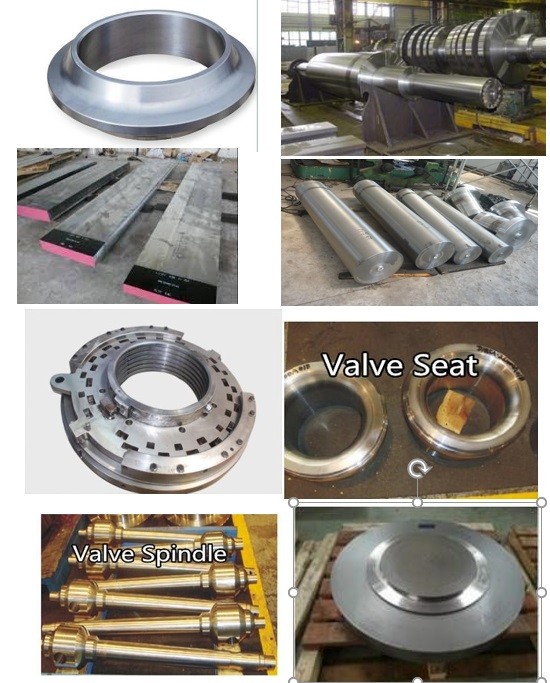

Following is the shape of AMS 5754 forging steel material that we could do is:AMS 5754 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5754 Forged forging steel rings seamless rolled rings,AMS 5754 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5754 Forged Forging Steel Discs Disks Blocks plates,AMS-5754 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5754 material that is used in following industry

AMS 5754 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AMS 5754 forged forging furnace rolls

AMS 5754 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars, nozzle vane.

AMS 5754 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AMS 5754 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5754 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings,valve trim, valve core, valve discs

AMS 5754 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

AMS 5754 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintle

AMS 5754 is non-magnetic. It has high strength up to 1500°F (816°C) and good oxidation resistance up to 2200°F(1204°C). This alloy is especially resistant to carburization and nitriding, conditions which cause failure insome high temperature alloys. It is used extensively in high temperature jet engine and chemical processing applications and is highly resistant to stress corrosion cracking in petrochemical applications

Forgings AMS 5754 maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

AMS 5754 are furnished in the solution heat-treated condition unless otherwise specified. X alloy is typically solution heat-treated at 2150°F (1177°C) and rapid cooled. Bright annealed products are cooled in hydrogen. Annealing at temperatures lower than the solution heat- treating may cause precipitation of secondary phases, which may affect the alloy’s strength and ductility.

AMS 5754 has wide use in gas turbine engines for combustion zone components such as transition ducts, combustor cans, spray bars and flame holders as well as in afterburners, tailpipes and cabin heaters. It is recommended for use in industrial furnace applications because it has unusual resistant to oxidizing, reducing and neutral atmospheres. Furnace rolls of this alloy were still in good condition after operating for 8,700 hours at 2150°F (1177°C). HASTELLOY® X alloy is also used in the chemical process industry for retorts, muffles, catalyst support grids, furnace baffles, tubing for pyrolysis operations and flash drier components.

The forgings AMS 5754 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Following is forging methods of AMS 5754 forging material

it is carried out at temperatures of from 1750 to 2200 Deg. F. The minimum temperature is dependent on the nature and degree of working. Here are some general rules that should be followed in forging HASTELLOY alloy X:

Soak billets or ingots one hour at forging temperature for each inch of thickness.

Reheat the alloy each time temperature drops to a point where further reduction might tend to fracture the metal.

Do not raise forging temperature to compensate for loss of heat. This may cause incipient melting.

In forging ingots, use light, rapid blows until cast structure is broken up. After cast structure is broken up, heavy blows may be used.

Do not attempt to change the general shape of an ingot, as from square to round, during the initial stages of forging. Work from square to octagon. Then round off the octagon using V-shaped bottom die.

Chemical composition of AMS 5754 forging turbine parts is as

Carbon - .05 / 0.15 max

Mn Manganese - 1 max

P Phosphorous - .040 max

S Sulfur - .030max

Si Silicon - 1 max

Cr Chromium - 20.50 / 23.00 max

Ni Nickel - Balance

Mo Molybdenum - 8.0 / 10.0 max

Ti Titanium - .15 max

Al Aluminum - .50 max

Fe Iron - 17 / 20 max

B Boron - .01 max

Co Cobalt - .50 / 2.50 max

W Tungsten - .20 / 1.00 max

Cu Copper - .50 max

mechanical property of for AMS 5754 forged round bars is as follow

Properties Metric Imperial

Tensile strength 755 MPa 109.5 Ksi

Yield strength 385 MPa 55.9 Ksi

Elastic modulus 205 GPa 29.8 psi

Reduction of area 22% 22%

Hardness, Rockwell B (converted from Brinell hardness) 87 87

All our AMS 5754 forging parts can be release en10204-3.1 certificate, or en10204-3.2 inspection certificate from following third party,3.2 mit TUV ,GL (Germanischer Lloyd),BV (Bureau Veritas),DNV (Det Norske Veritas),ABS (American Bureau of Shipping),Lloyds Register of Shipping, RMRS (Russian Maritime Register of Shipping),RINA (Registro Italiano Navale)

For Every pieces of AMS 5754 forging round bars, we could do following testing Non destructive tests such as visual, dimensional, ultrasonic testing,dye penetrant testing , Magnetic particle test(MPl), the mirrostructure and technological tests such as tensile, resilience, creep tests, hardness,Metallographic exams,Chemical analysis

Welcome your inquiry of AMS 5754 forging parts

Following is the shape of AMS 5754 forging steel material that we could do is:AMS 5754 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5754 Forged forging steel rings seamless rolled rings,AMS 5754 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5754 Forged Forging Steel Discs Disks Blocks plates,AMS-5754 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5754 material that is used in following industry

AMS 5754 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AMS 5754 forged forging furnace rolls

AMS 5754 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars, nozzle vane.

AMS 5754 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AMS 5754 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5754 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings,valve trim, valve core, valve discs

AMS 5754 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

AMS 5754 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintle

AMS 5754 is non-magnetic. It has high strength up to 1500°F (816°C) and good oxidation resistance up to 2200°F(1204°C). This alloy is especially resistant to carburization and nitriding, conditions which cause failure insome high temperature alloys. It is used extensively in high temperature jet engine and chemical processing applications and is highly resistant to stress corrosion cracking in petrochemical applications

Forgings AMS 5754 maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

AMS 5754 are furnished in the solution heat-treated condition unless otherwise specified. X alloy is typically solution heat-treated at 2150°F (1177°C) and rapid cooled. Bright annealed products are cooled in hydrogen. Annealing at temperatures lower than the solution heat- treating may cause precipitation of secondary phases, which may affect the alloy’s strength and ductility.

AMS 5754 has wide use in gas turbine engines for combustion zone components such as transition ducts, combustor cans, spray bars and flame holders as well as in afterburners, tailpipes and cabin heaters. It is recommended for use in industrial furnace applications because it has unusual resistant to oxidizing, reducing and neutral atmospheres. Furnace rolls of this alloy were still in good condition after operating for 8,700 hours at 2150°F (1177°C). HASTELLOY® X alloy is also used in the chemical process industry for retorts, muffles, catalyst support grids, furnace baffles, tubing for pyrolysis operations and flash drier components.

The forgings AMS 5754 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Following is forging methods of AMS 5754 forging material

it is carried out at temperatures of from 1750 to 2200 Deg. F. The minimum temperature is dependent on the nature and degree of working. Here are some general rules that should be followed in forging HASTELLOY alloy X:

Soak billets or ingots one hour at forging temperature for each inch of thickness.

Reheat the alloy each time temperature drops to a point where further reduction might tend to fracture the metal.

Do not raise forging temperature to compensate for loss of heat. This may cause incipient melting.

In forging ingots, use light, rapid blows until cast structure is broken up. After cast structure is broken up, heavy blows may be used.

Do not attempt to change the general shape of an ingot, as from square to round, during the initial stages of forging. Work from square to octagon. Then round off the octagon using V-shaped bottom die.

Chemical composition of AMS 5754 forging turbine parts is as

Carbon - .05 / 0.15 max

Mn Manganese - 1 max

P Phosphorous - .040 max

S Sulfur - .030max

Si Silicon - 1 max

Cr Chromium - 20.50 / 23.00 max

Ni Nickel - Balance

Mo Molybdenum - 8.0 / 10.0 max

Ti Titanium - .15 max

Al Aluminum - .50 max

Fe Iron - 17 / 20 max

B Boron - .01 max

Co Cobalt - .50 / 2.50 max

W Tungsten - .20 / 1.00 max

Cu Copper - .50 max

mechanical property of for AMS 5754 forged round bars is as follow

Properties Metric Imperial

Tensile strength 755 MPa 109.5 Ksi

Yield strength 385 MPa 55.9 Ksi

Elastic modulus 205 GPa 29.8 psi

Reduction of area 22% 22%

Hardness, Rockwell B (converted from Brinell hardness) 87 87

All our AMS 5754 forging parts can be release en10204-3.1 certificate, or en10204-3.2 inspection certificate from following third party,3.2 mit TUV ,GL (Germanischer Lloyd),BV (Bureau Veritas),DNV (Det Norske Veritas),ABS (American Bureau of Shipping),Lloyds Register of Shipping, RMRS (Russian Maritime Register of Shipping),RINA (Registro Italiano Navale)

For Every pieces of AMS 5754 forging round bars, we could do following testing Non destructive tests such as visual, dimensional, ultrasonic testing,dye penetrant testing , Magnetic particle test(MPl), the mirrostructure and technological tests such as tensile, resilience, creep tests, hardness,Metallographic exams,Chemical analysis

Welcome your inquiry of AMS 5754 forging parts