Description

Jiangsu Liangyi professional manufacturer of A182-F6NM(UNS S41500,AISI 415,ASTM A182 Grade F6NM,F 6NM,Grade F6NM) open die forging parts and seamless rolled steel forged rings from china

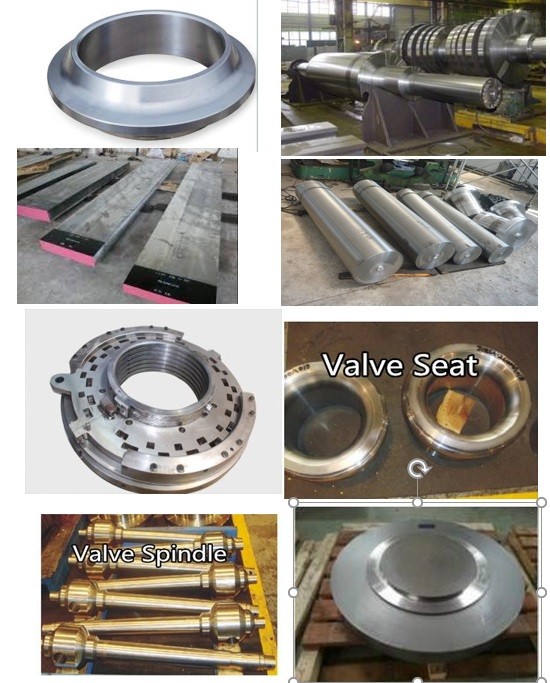

Following is the shape of A182-F6NM(UNS S41500,AISI 415,ASTM A182 Grade F6NM,F 6NM,Grade F6NM)forging steel material that we could do is:A182-F6NM Forged Steel round bars square bars Flat bars Rectangles Bars Rods,UNS S41500 Forged forging steel rings seamless rolled rings,ASTM A182 Grade F6NM Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,F6NM Forged Forging Steel Discs Disks Blocks plates,AISI 415 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of A182-F6NM(UNS S41500,AISI 415,ASTM A182 Grade F6NM,F 6NM,Grade F6NM) material that is used in following industry

F6NM Forged Forging Steel Francis Hydro Power Hydraulic Turbine Generator Wicked Wicket Gate, Guide Vanes

F6NM forged steel hydropower pelton bucket Forged Forging Flat Steel Bars

ASTM A182 Grade F6NM Forged Forging Hydropower Francis Pelton Turbine runners,Turbine runners Discs DisksF6NM Forged Forged Pumps suction side sealing jacket seal chambers jacket casings

UNS S41500 Forged Forging Swivel Ring Flanges

AISI 415 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

Grade F6NM Forged Forging Swept branches outlets steel fittings swept saddles

UNS S41500 Forged Forging Steel double studded adapter flange

F6NM Forged Forging Steel Nuclear Power trunnions

A182-F6NM Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

UNS S41500 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AISI 415 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Grade F6NM Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

ASTM A182 Grade F6NM forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AISI 415 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

F 6NM Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

F6NM forged steel Mechanical Seal Discs

UNS S41500 Forged Forging Marine Ship Boat Propeller Shafts

UNS S41500 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AISI 415 Forged Forging Gas Air Compressor Rotor

F6 NM Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

ASTM A182 Grade F6NM Forged Forging Block Adaptor

ASTM A182 Grade F6NM Forged Forging venturi cone meter Body Bodies Blocks

F6NM Forged Forging Steel frac pumps Fluid End Body Bodies Blocks Modules

Grade F6NM Forged Forging Steel gate valves Body Bodies bespoke flat bars

F6NM Forged Forging Steel drill head casings,collars,landing bowls

F6NM forging forged steel Couplings

A182-F6NM forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

UNS S41500 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AISI 415 Forged Forging Steel Subsea X Tree high pressure elbow

F6 NM forged forging Steel wellhead locknut Venturi Bench

ASTM A182 Grade F6NM Forged Forging Steel double studded adapter flange

F6NM Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

F6NM forged steel Downhole drilling tool Mud Motor End Caps

UNS S41500 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

F6NM Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

ASTM A182 Grade F6NM Forged Forging Steel Pressure Vessel STUDDING OUTLET

AISI 415 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Grade F6NM forging Forging/Forged Steel Wellhead Christmas Tree Frac Head (Fracturing Head)

A182-F6NM Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

A182-F6NM Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

ASTM A182 Grade F6NM Forged Forging forge Steel transition Cone

UNS S41500 Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

ASTM A182 Grade F6NM forged forging steel Load Cell

ASTM A182 Grade F6NM forging steel Homogeniser Homogenising Pumping pistons Plunger

ASTM A182 Grade F6NM Forging (forged) Bowl Body/Bodies for Centrifugal Machines and Decanters, Decanter Centrifuge

A182-F6NM is martensitic stainless steel. It is a chromium stainless steel with added nickel and molybdenum to its composition. It offers its excellence in corrosion resistance and zero notch ductility. Grade F6NM is air-hardened stainless steel. Usually, it is available in quenched and tempered condition. Its machinability is limited to 23HRC. Its approved hardness limit is restricted to 75KSI.

F6NM forged steel is used often in applications that require weldability with corrosion resistance. Grade F6NM is primarily used in the oil industry and components of power plants and reactors, turbine construction, etc

FOllowing is forging methods of UNS S41500 forged steel material, :

NACE MR-0175/ISO 15156

ASTM A182/182M

ASTM A276/276M

ASTM A479/479M

FOllowing is chemical compostion of A182-F6NM(UNS S41500,AISI 415,ASTM A182 Grade F6NM,F 6NM,Grade F6NM)forged steel rings

C 0.05 Max

P 0.030 Max

Cr 11.5 – 14.0

Si 0.60 Max

S 0.030 Max

Ni 3.50 ‐ 5.50

Mn 0.50 ‐ 1.00

Mo 0.50 ‐ 1.00

Following of A182-F6NM forging parts mechanical property :

0.2% Yield Strength - 75000 PSI min

Tensile Strength - 95000 PSI min

Elongation - 18% min

Reduction of Area - 35% min

Hardness - 23 HRC max

Charpy V-Notch @ 60 DEG C - 42/34 Joules

We have Heat treatment Equipments of make forged of A182-F6NM forged parts: φ2*12m pit furnace; φ8*3*3m table resistor furnace; 1.5*0.8*1.5m box resistor furnace; 8*3*3m gas furnace; 6*3*2m gas furnace; 7.5*4*2.5 gas furnace;16*2.5*2.5 gas furnace etc.

Also we have following Machining Equipments of maching F6NM forged material, ; including φ2*12m heavy sleeper; φ5m vertical lathe; floor type boring and milling machine; CNC miller ;φ1.6*16m heavy sleeper; single-arm planer; boring and milling machine etc.

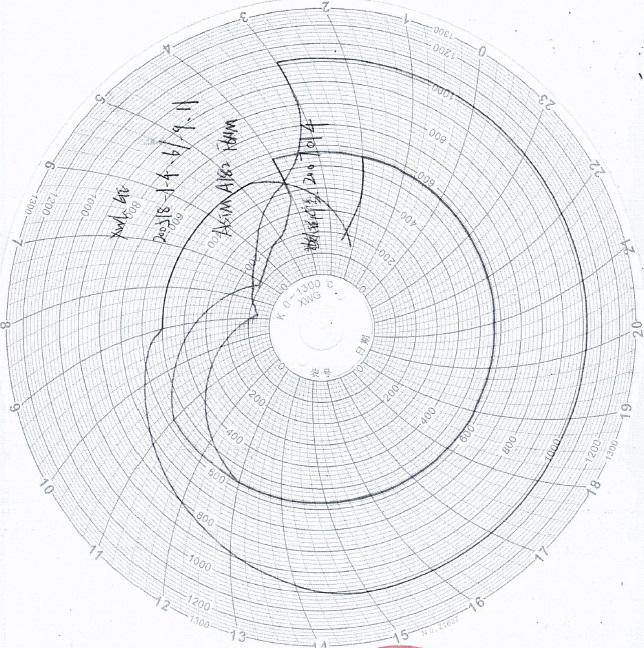

Heat Treatment Inspection Report of F6NM forged parts

Report No:200812088999

|

Customer |

GHECO One Power Plant |

|||||||||

|

Model No of thermal treatment Furnace |

Trolley-type resistance furnace |

|||||||||

|

HT Process |

Q+T |

Heat treatment No. |

2007014 |

|||||||

|

Drawing No |

Item No |

Job No. |

Material Grade |

Quantity |

Steel ingot No. |

|||||

|

H-506800MEF24 |

Forged rings |

XWL-HK200518-1-4 |

ASTM A182 F6NM |

1 |

2005A-V08 |

|||||

|

H-506800MEF24 |

Forged rings |

XWL-HK200518-1-6 |

ASTM A182 F6NM |

1 |

2005A-V08 |

|||||

|

H-506800MEF24 |

Forged rings |

XWL-HK200518-1-7 |

ASTM A182 F6NM |

1 |

2004A-V116 |

|||||

|

H-506800MEF24 |

Forged rings |

XWL-HK200518-1-8 |

ASTM A182 F6NM |

1 |

2005A-V17 |

|||||

|

H-506800MEF24 |

Forged rings |

XWL-HK200518-1-9 |

ASTM A182 F6NM |

1 |

2005A-V17 |

|||||

|

H-506800MEF24 |

Forged rings |

XWL-Hk200518-1-11 |

ASTM A182 F6NM |

1 |

2005A-V17 |

|||||

|

|

||||||||||

|

Result |

Qualified or not |

Inspector |

chengxin |

|||||||

|

Inspection |

ok |

Inspect Date |

2020-07-10 |

|||||||

|

|

juyou |

|||||||||

|

|

2020-07-10 |

|||||||||

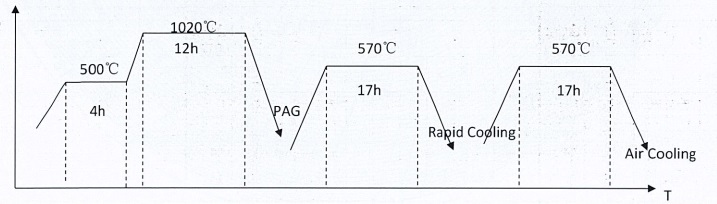

A182-F6NM forged parts heat treatment chart is as following

Ultrasonic test report of A182-F6NM forged material

|

|

ULTRASONIC TEST REPORT

|

Report Nrt:

|

||||||||||||||||

|

UT200812-1-12 |

||||||||||||||||||

|

1/2 |

||||||||||||||||||

|

|

Date:

|

|||||||||||||||||

|

2020/8/12 |

||||||||||||||||||

|

|

Client:

|

Purchase Order:

|

Part Designation:

|

Part Assembly or Item N°:

|

Unit:

|

Language:

|

||||||||||||

|

I |

|

41020048899 |

F6NM forged rings |

200518-1-11 |

3 |

English/Chinese |

||||||||||||

|

Drawing:

|

MPP/CP or ITP Step: |

Material Designation:

|

Heat Number:

|

|||||||||||||||

|

H-506800MEF24-271FTP-71 |

A |

8 |

ASTM A182 F6NM |

2005A-V17 |

||||||||||||||

|

OBJECT AND SCOPE OF TEST |

||||||||||||||||||

|

|

||||||||||||||||||

|

REFERENCE DOCUMENT |

||||||||||||||||||

|

Procedure Number

|

|

|||||||||||||||||

|

Method/Standard

|

ASTM/ASME: |

EN/SO: |

Other: |

|||||||||||||||

|

ASTM A388/A388M |

|

|

||||||||||||||||

|

Acceptance Criterias

|

ASTM/ASME: |

EN/SO: |

Other: |

|||||||||||||||

|

ASTM A388/A388M |

|

|

||||||||||||||||

|

EXAM CONDITIONS |

|

|||||||||||||||||

|

Part Inspected

|

Casting □

|

Forging ☑

|

Welding □

|

Rolled Bars

|

Rolled Steel Plate

|

|||||||||||||

|

Inspection stage

|

Excavation □

|

Chamfer □

|

Repaired Weld □

|

Construction Weld □

|

Final inspection ☑

|

|||||||||||||

|

Before HT □

|

After HT ☑

|

Before Machining □

|

After Machining ☑

|

Intermediate Inspection

|

||||||||||||||

|

Surface conditions

|

Rough □

|

Sand Blasted □

|

Machined ☑

|

Blasted □

|

Grinded □

|

|||||||||||||

|

Part temperature (℃)

|

28 |

Surf. Roughness (μm)

|

6.3 |

Surface preparation

|

Ok ☑

|

Not Ok □

|

||||||||||||

|

MATERIAL USED |

||||||||||||||||||

|

|

Brand |

Type

|

Serial #

|

Calibration due date

|

||||||||||||||

|

Device

|

GE |

USM 35XS |

9244a |

2021/2/16 |

||||||||||||||

|

Calibration Block

Reference Block |

/ |

/ Φ6 Flat Bottom Hol |

/ |

|

||||||||||||||

|

|

|

Φ6mm Long Horizontal Hole |

|

/ |

||||||||||||||

|

Coupling Media

|

|

0i1 |

|

/ |

||||||||||||||

|

PROBES

|

||||||||||||||||||

|

Number

|

Brand/Type

|

Dim.(mm)

|

Freq. (MHz) (MHz) |

Real Angle (*)

|

Ref Level (dB)

|

dB Correction

|

Eval. Level (dB) ) |

Control Level (dB)

|

Range (mm)

|

|||||||||

|

57745 |

GE/B2 S |

024 |

2 |

0 |

36 |

2 |

22 |

60 |

400 |

|||||||||

|

58414 |

GE/SWB45-2 |

14*14 |

2 |

45 |

40 |

3 |

26 |

69 |

350 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Control Level =Reerence level +dB correction +Evaluation Level

|

||||||||||||||||||

|

OPERATING PROCESS |

||||||||||||||||||

|

Preliminary Checks

|

Probe index ☑

|

Beam angle □

|

Calbrations ☑

|

Range & Sensitivity ☑

|

dB Correction ☑

|

General Conditions ☑ 一 |

||||||||||||

|

Reference setting

|

DAC ☑ |

DGS □ |

Type of reflector

|

Flat Bottom Hole

|

Reflector size (mm)

|

06 |

||||||||||||

|

Parent Material Scanning

|

Yes □

|

No □

|

Evaluation level (dB)

|

|

|

|||||||||||||

|

Type of Indication Searched

|

Longitudinal ☑

|

Transversal ☑

|

|

|||||||||||||||

|

Final Cleaning

|

Yes ☑

|

Product / Type

|

Forging

|

Lot#/Use by date

|

|

|||||||||||||

|

CONCLUSION

|

Acceptable

|

Acceptable with recordable indication □

|

Not acceptable □

|

|||||||||||||||

|

Comments / NC Number

|

|

|||||||||||||||||

MAGNETOSCOPIC TEST REPORT of UNS S41500 Forged parts is as following

|

|

MAGNETOSCOPIC TEST REPORT |

Report Nr°: |

|||||||||||||||

|

MT200812-2-12 |

|||||||||||||||||

|

1/2 |

|||||||||||||||||

|

|

|

||||||||||||||||

|

2020/8/12 |

|||||||||||||||||

|

|

Client: |

Purchase Order: |

Part Designation: |

Part Assembly or Item N°: |

Unit: |

Language: |

|||||||||||

|

GHECO One Power Plant |

41020048899 |

F6NM forged rings |

200518-1-11 |

3 |

English/Chinese |

||||||||||||

|

Drawing: |

Rev: |

MPP/CP or ITP Step: MPP/CP ITP |

Material Designation: |

Heat Number: |

|||||||||||||

|

H-506800MEF24 |

A |

8 |

ASTM A182 F6NM |

2005A-V17 |

|||||||||||||

|

OBJECT AND SCOPE OF TEST/ |

|||||||||||||||||

|

|

|||||||||||||||||

|

REFERENCE DOCUMENT/ |

|||||||||||||||||

|

Procedure Number |

|

||||||||||||||||

|

Method/Standard |

ASTM/ASME: |

EN/ISO: |

Other: |

||||||||||||||

|

ASTM A788/A788M |

|

|

|||||||||||||||

|

Acceptance Criterias |

ASTM/ASME: |

EN/ISO: |

Other: |

||||||||||||||

|

ASTM A788/A788M |

|

|

|||||||||||||||

|

EXAM CONDITIONS |

|

||||||||||||||||

|

Part Inspected |

Casting □ |

Forging ☑ |

Welding □ |

Rolled Bars □ |

Rolled Steel Plate |

||||||||||||

|

Inspection stage |

Excavation □ |

Chamfer □ 口 |

Repaired Weld □ |

Construction Weld □ |

Final inspection □ |

||||||||||||

|

Before HT □ |

After HT ☑ |

Before Machining □ |

After Machining ☑ |

Intermediate Inspection □ |

|||||||||||||

|

Surface conditions |

Rough □ |

Sand Blasted □ |

Machined ☑ |

Blasted □ |

Grinded □ |

Brushed □ |

|||||||||||

|

Lightning conditions |

Natural ☑ |

Artificial □ |

UV □ |

|

|||||||||||||

|

Illuminance(Lux) |

≥1076LUX |

UV-A irradiance(μW/cm2) (μW/cm2) |

|

||||||||||||||

|

Par temperature(℃) |

28 |

Surf. Roughness (μm) |

≤6.3 |

Surface preparation |

Ok ☑ |

Not Ok □ |

|||||||||||

|

MATERIAL USED |

|

|

|||||||||||||||

|

|

Brand |

Type |

Serial # |

Calibration due date |

|||||||||||||

|

Device |

Y-7 |

Yoke |

640032 |

2021/2/17 |

|||||||||||||

|

UV Light |

/ |

/. |

/ |

/ |

|||||||||||||

|

Luxmeter |

1330A |

White Light |

150802236 |

2021/7/8 |

|||||||||||||

|

Radiometer |

/ |

/ |

/ |

/ |

|||||||||||||

|

Field-strength meter |

HT208 |

TesIa Meter |

BH01295 |

2021/7/8 |

|||||||||||||

|

Flux indicators |

Afnor#1 □ |

Afnor # 2 □ |

Berthold □ |

ASME □ |

Other □ |

|

|||||||||||

|

OPERATING PROCESS / |

|

||||||||||||||||

|

Cleaning |

Yes ☑ |

No |

Product/ Type |

HR-ST |

Lot#/Use by date |

200322 |

|||||||||||

|

Contrast media |

Yes |

No ☑ |

Product/ Type |

|

Lot #/ Use by date |

|

|||||||||||

|

Detection media |

Continuous☑ |

Post eval. |

Product/ Type |

HD-OB |

Lot #/ Use by date |

200322 |

|||||||||||

|

Wet ☑ |

Dry |

Coloured □ |

Fluorescent □ |

||||||||||||||

|

Magnetization |

Magnetization type |

Current ☑ |

Flow |

Magnetization technique 磁 |

Portable electromagnet(yoke) |

||||||||||||

|

Current type |

AC □ |

DC ☑ |

Intensity(A/m) (A/m) |

≥2400 |

Magnetization time |

3s |

|||||||||||

|

Spacing |

Prods |

Yokes ☑ |

Distance(mm) |

100 |

|||||||||||||

|

Demagnetization |

Yes □ |

No ☑ |

Technique |

|

Residual Field |

|

|||||||||||

|

Final Cleaning |

Yes ☑ |

No □ |

Product / Type |

HR-ST |

Lot#/Use by date |

200322 |

|||||||||||

|

CONCLUSION |

Acceptable ☑ |

Acceptable with recordable indication □ |

Not acceptable □ |

||||||||||||||

|

Comments /NC Number |

|

||||||||||||||||

Hardness Test Report of A182-F6NM forged sleeves

|

Client Company |

GHECO-One Power Plant |

Sample Name |

F6NM forged sleeves |

|

|

Job No. |

XWL-HE200518-1-11 |

Drawing |

H-506800MEF24 |

|

|

Material |

ASTM A182 F6NM |

Heat NO. |

2005A-V17 |

|

|

|

||||

|

Material |

Hardness Test |

|||

|

|

||||

|

Standard |

BHN≤295 |

(BHN) |

277 268 273 |

|

|

Test Means |

GB/T 231 |

Test Result |

ACCEPTABLE |

|

|

|

||||

|

|

Examiner: hongy |

Date: 2020-8-12 |

||

AISI 415 Forgings Mechanical Property Test Report

|

Client Company |

GHECO One Power Plant |

Chart No. |

H-506800MEF24 |

|||||

|

|

|

Unit No |

4# |

|||||

|

Job No. |

XWL-HE200518-1-11 |

Heat No. |

2005A-V17 |

|||||

|

Description |

F6NM forged parts |

Material |

ASTM A182 F6NM |

|||||

|

Test Item |

Tensile test Impact test |

Temperature |

20 |

|||||

|

Standard |

Location |

Tensile Strength (Mpa) |

Yield Strength Rp0.2(Mpa) |

Elongation (%) |

Reduction (%) |

|||

|

≥790 |

≥620 ≥620 |

≥15 |

≥45 |

|||||

|

Tensile Result |

Longitudinal |

900 |

835 |

16.0 |

64 |

|||

|

/ |

/ |

/ |

/ |

/ |

||||

|

Standard |

Location |

Temperature(℃) |

Type of Notch |

Dimension of Specimen |

Impact Value (J) |

|||

|

-20 |

AkV |

10*10*55 |

≥32 |

|||||

|

Impact Result |

Longitudinal |

-20 |

AkV |

10*10*55 |

156 |

146 |

173 |

|

|

/ |

/ |

/ |

/ |

/ |

/ |

/ |

||

|

Methods |

ASTM A370 ASTMA370 ASTM E23 |

|||||||

|

Conclusion |

Acceptable |

|||||||

|

Tester juinx |

Examiner chejiao |

date:2020-07-23 |

||||||

Welcome your inquiry of A182-F6NM(UNS S41500,AISI 415,ASTM A182 Grade F6NM,F 6NM,Grade F6NM) forging forged steel parts