Description

Jiangsu Liangyi professional manufacturer of 1.4534(X3CrNiMoAl13-8-2,X 3 CrNiMoAl 13-8-2,X3CrNiMoAl1382,X3CrNiMoAl13.8.2)open die forging parts and seamless rolled steel forged rings from china

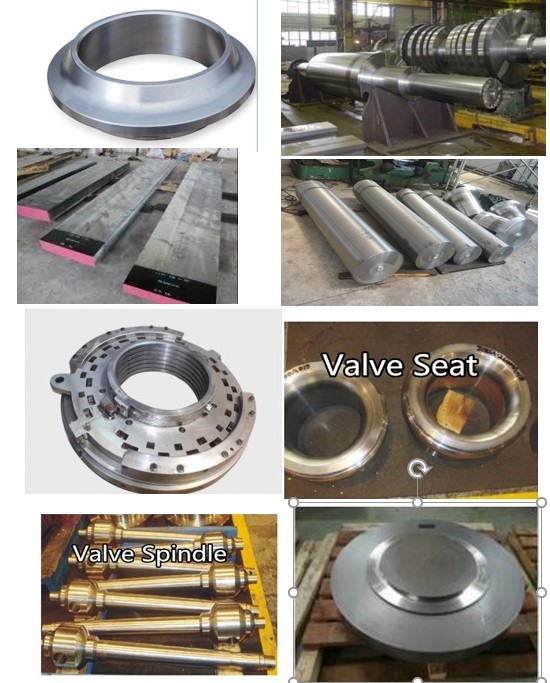

Following is the shape of 1.4534(X3CrNiMoAl13-8-2,X 3 CrNiMoAl 13-8-2,X3CrNiMoAl1382,X3CrNiMoAl13.8.2) forging steel material that we could do is:1.4534 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X 3 CrNiMoAl 13-8-2,Forged forging steel rings seamless rolled rings,X3CrNiMoAl13-8-2 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X3CrNiMoAl1382 Forged Forging Steel Discs Disks Blocks plates,X3CrNiMoAl13.8.2 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4534(X3CrNiMoAl13-8-2,X 3 CrNiMoAl 13-8-2,X3CrNiMoAl1382,X3CrNiMoAl13.8.2) material that is used in following industry

1.4534 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

X3CrNiMoAl13-8-2 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

X3CrNiMoAl13.8.2 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

X3CrNiMoAl1382 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

1.4534 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4534 Forged Forging ultra high pressure water jet Waterjet cutting Machine Cutter Hydraulic Cylinder,accumulator attenuator

X3CrNiMoAl13-8-2 forged steel ultra high pressure water jet Waterjet cutting Machine Cutter intensifier pump Sealing Heads

X3CrNiMoAl1382 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

X3CrNiMoAl13.8.2 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

X3CrNiMoAl1382 Forged Forging Marine Ship Boat Propeller Shafts

1.4534 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

X3CrNiMoAl13-8-2 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

1.4534 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X3CrNiMoAl13-8-2 forging injection molding,mould, dies block,tooling

X3CrNiMoAl13.8.2 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X3CrNiMoAl13.8.2 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

1.4534(X3CrNiMoAl13-8-2) is acid resistant special steel with martensitic structure, subjected to precipitation hardening, showing excellent mechanical properties - high hardness, strength and relatively high corrosion resistance, dynamic loads and cracking resistive.Compared to other high alloyed grades exhibiting corrosion resistance, 1.4534(X3CrNiMoAl13-8-2) steel has much more limited acceptability of sulfur and phosphorus in its chemical composition, which demonstrates a relatively difficult manufacturing process and high purity and quality of steel.In aggressive environments (excluding moisture resistance) the species exhibits very good resistance to NaCl, Nitric Acid, and Sodium Hydroxide.The 1.4534(X3CrNiMoAl13-8-2) is mainly used in the aerospace, nuclear, and petrochemical industries for parts and components subject to corrosion and heavy loads,aerospace, medical technology, high-pressure pumps, valves and high-strength bolts.and so on

1.4534(X3CrNiMoAl13-8-2) stainless has displayed excellent resistance to oxidation up to approximately 1100°F. Long-term exposure to temperatures between about 600-900°F (288-482°C) can result in reduced toughness in precipitation hardenable stainless steels. The reduction in toughness can be minimized in some cases by using higher aging temperatures. Short exposures to elevated temperatures can be considered, provided the maximum temperature is at least 50°F (28°C) less than the aging temperature.

FOllowing is chemical compostion of 1.4534(X3CrNiMoAl13-8-2) forged steel sleeves

C: max. 0,05 %

Cr: 12,25 - 13,25 %

Mn: max. 0,1 %

Mo: 2,0 - 2,5 %

Ni: 7,5 - 8,5 %

P: max. 0,01 %

S: max. 0,008 %

Si: max. 0,1 %

Ti: max. 0,1 %

N: max. 0,01 %

Al: 0,8 - 1,35 %

Following of 1.4534(X3CrNiMoAl13-8-2) forging parts mechnical property :

ypical mechanical properties (room temperature)

H950

Yield strength min. 1413 MPa

Tensile strength min. 1517 MPa

Elongation min. 10 %

H1000

Yield strength min. 1310 MPa

Tensile strength min. 1413 MPa

Elongation min. 10 %

H1050

Yield strength min. 1138 MPa

Tensile strength min. 1207 MPa

Elongation min. 12 %

Following is forging process of 1.4534(X3CrNiMoAl13-8-2)forging steel parts

Forging process flow quality control: Raw material steel ingot into warehouse(test the chemical content) → Cutting→ Forged process→ Post forging heat treatment(N+T)→ UT→ Rough Machining→ UT → QT→ Inspection(UT, mechanical properties, hardness, grain size)→ Grooving→ Stress relieve Tempering → Machining holding postion for rotor when HST→ HST→ Inspection (dimension)→ Packing and Marking(steel stamp, mark)→ Storage Shipment

Welcome your inquiry of 1.4534 / X3CrNiMoAl13-8-2 forging forged steel parts