Description

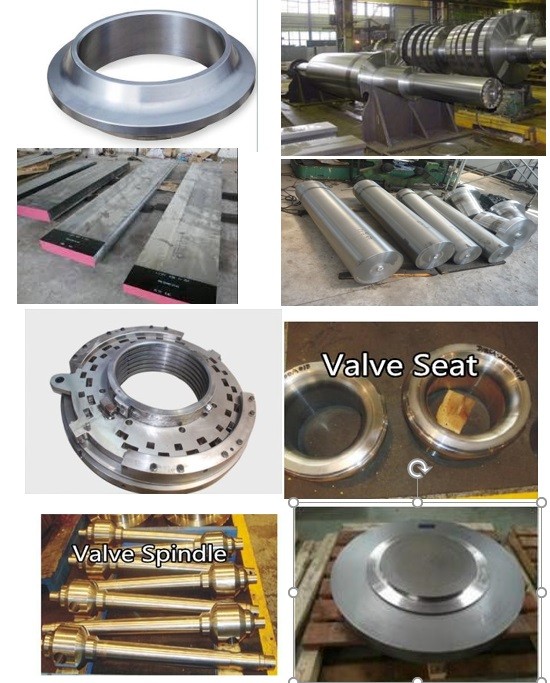

Jiangsu Liangyi is professional manufacturer of 1.3917 ,Ni 42 open die forging parts and seamless rolled steel forged rings from china

Following is the shape of 1.3917 ,Ni 42 forging steel material that we could do is:Ni 42 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Ni 42 Forged forging steel rings seamless rolled rings,1.3917 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.3917 Forged Forging Steel Discs Disks Blocks plates,Ni 42 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

1.3917 ,Ni 42 is a nickel-iron alloy that contains 41% nickel and exhibits excellent controlled expansion qualities and is used primarily for controlled expansion and magnetic applications. 1.3917is also highly effective in magnetic applications. It can be hot formed, cold formed or machined. 1.3917 possesses many of the qualities of the other Invar nickel iron alloys. It is effective in extreme temperatures ranging from -32C to 275C.

FOllowing is melting methods of 1.3917 ,Ni 42 forged parts

Material shall be produced by a triple melt process consisting of vacuum induction melting (VIM)followed by electroslag consumable electrode remelting (ESR)and vacuum arc consumable electrode remelting VAR).

A detailed manufacturing and quality control plan (MQCP)shall be established from us .The plan shall include,for each re-melting method (VIM,ESR,VAR)all the significant operations with frozen parameters. The Supplier shall define internal documentation covering the following as a minimum:

a.Raw material procurement and control (VIM)

b.Type of raw material (Virgin material,revert)and limits on the quantity of each. c.Method used to control the chemical composition.

d.Method used to ensure absence of foreign and non-metallic material.

e.Method for cleaning and inspection of furnaces and electrodes to ensure absence of defects.

f.Method to ensure full traceability of each heat and electrodes.

g.Surface cleaning and conditioning of the ESR ingot for subsequent VAR processing.

h.Method used to ensure absence of foreign and non-metallic material of the produced VAR ingot.

FOllowing is chemical compostion of Ni 42 forged steel rings

Carbon (C%)≤0,05

Silicon (Si%)≤0,30

Manganese (Mn%)≤1,00

Nickel (Ni%)41,0-43,0 (40,0-43,0)

Following of Ni 42 forging parts heat treatment mechanical property Delivery condition :

Metallurgical Condition Annealed, Descaled

Yield Strength KSI (MPa) 36 (248)

Tensile Strength KSI (MPa) 71 (490)

Hardness HB 130

Elongation 50mm >40

ALl our finished forged 1.3917 ,Ni 42 parts should be accepted by the QC department of the manufacturer by conducting the following

examinations:

1) external examination;

2) a check of dimensions and marking;

3) chemical composition examination;

4) mechanical tests;

5) macrostructure examination;

6) residual stress measurement;

7) ultrasonic testing;

8) periscopic testing.

Welcome your inquiry of 1.3917 ,Ni 42 forging forged steel parts

Following is the shape of 1.3917 ,Ni 42 forging steel material that we could do is:Ni 42 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Ni 42 Forged forging steel rings seamless rolled rings,1.3917 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.3917 Forged Forging Steel Discs Disks Blocks plates,Ni 42 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

1.3917 ,Ni 42 is a nickel-iron alloy that contains 41% nickel and exhibits excellent controlled expansion qualities and is used primarily for controlled expansion and magnetic applications. 1.3917is also highly effective in magnetic applications. It can be hot formed, cold formed or machined. 1.3917 possesses many of the qualities of the other Invar nickel iron alloys. It is effective in extreme temperatures ranging from -32C to 275C.

FOllowing is melting methods of 1.3917 ,Ni 42 forged parts

Material shall be produced by a triple melt process consisting of vacuum induction melting (VIM)followed by electroslag consumable electrode remelting (ESR)and vacuum arc consumable electrode remelting VAR).

A detailed manufacturing and quality control plan (MQCP)shall be established from us .The plan shall include,for each re-melting method (VIM,ESR,VAR)all the significant operations with frozen parameters. The Supplier shall define internal documentation covering the following as a minimum:

a.Raw material procurement and control (VIM)

b.Type of raw material (Virgin material,revert)and limits on the quantity of each. c.Method used to control the chemical composition.

d.Method used to ensure absence of foreign and non-metallic material.

e.Method for cleaning and inspection of furnaces and electrodes to ensure absence of defects.

f.Method to ensure full traceability of each heat and electrodes.

g.Surface cleaning and conditioning of the ESR ingot for subsequent VAR processing.

h.Method used to ensure absence of foreign and non-metallic material of the produced VAR ingot.

FOllowing is chemical compostion of Ni 42 forged steel rings

Carbon (C%)≤0,05

Silicon (Si%)≤0,30

Manganese (Mn%)≤1,00

Nickel (Ni%)41,0-43,0 (40,0-43,0)

Following of Ni 42 forging parts heat treatment mechanical property Delivery condition :

Metallurgical Condition Annealed, Descaled

Yield Strength KSI (MPa) 36 (248)

Tensile Strength KSI (MPa) 71 (490)

Hardness HB 130

Elongation 50mm >40

ALl our finished forged 1.3917 ,Ni 42 parts should be accepted by the QC department of the manufacturer by conducting the following

examinations:

1) external examination;

2) a check of dimensions and marking;

3) chemical composition examination;

4) mechanical tests;

5) macrostructure examination;

6) residual stress measurement;

7) ultrasonic testing;

8) periscopic testing.

Welcome your inquiry of 1.3917 ,Ni 42 forging forged steel parts