Description

Jiangsu Liangyi is professional manufacturer of Invar 36,ALLOY 36,UNS K93600,NILO 36 open die forging parts and seamless rolled steel forged rings from china

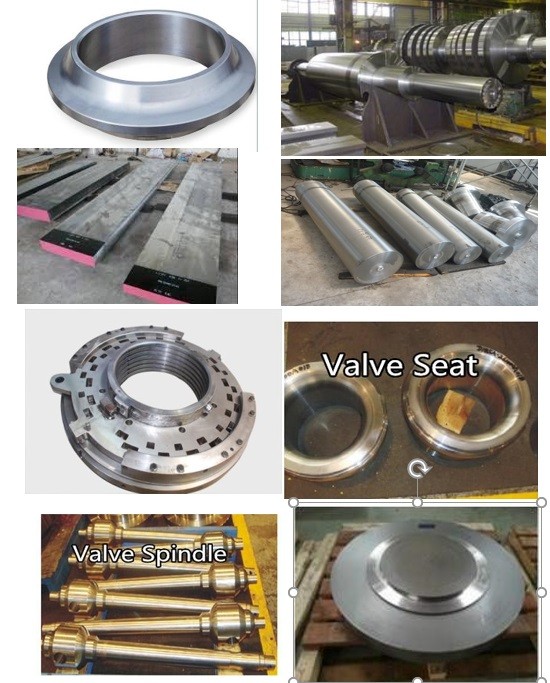

Following is the shape of Invar 36,ALLOY 36,UNS K93600,NILO 36 forging steel material that we could do is:ALLOY 36 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Invar 36 Forged forging steel rings seamless rolled rings,NILO 36 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.3817 Forged Forging Steel Discs Disks Blocks plates,UNS K93600 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Invar 36 a 36% nickel-iron alloy possessing a rate of thermal expansion approximately one-tenth that of carbon steel at temperatures up to 400°F(204°C), Invar 36 forged material is normally used in following industry: Piping for storage and transport of liquefied gases, Components for OLED screens, Measuring and control devices for temperatures below 200°C (392°F), e.g. for thermostats,Bushings for screw or rivet joints between various metals,Bi-metal components and thermostatic bi-metals, where Alloy 36 is the passive component, Forms for the production of carbon-fiber reinforced plastic (CFP), especially for the aerospace industry, Frameworks for electronic control units in satellites and space travel down to -200°C (-328°F),Support elements for electro-magnetic lenses in laser control units,Components for the automotive industry, Overhead power lines in an alloyed, age-hardenable variant,composite molds for the aerospace industry,bimetal thermostats,clock balance wheels,containers and transfer lines for LNG tankers,echo boxes and filters for mobile telephones

electrical circuit breakers & transformers,electron gun components,high voltage transmission lines,laser components,magnetic shielding,radar and microwave cavity resonators,scientific instruments

FOllowing is melting methods of 1.3817 forged parts

1. Step 1- Basic EF

Step 2- Either Argon Oxygen Decarburization (AOD) or Vacuum Oxygen Decarburization (VOD) or Vacuum Degrassing.

Step 3- Either Electroslag Remelting (ESR) or Electroflux Remelting (EFR) or Vacuum Arc Remelting (VAR).

Optional Step 4- Vacuum Arc Remelting (VAR)

OR

2. Step 1- Vacuum Induction Melting (VIM)

Step 2- Either Electroslag Remelting (ESR) or Electroflux Remelting (EFR) or Vacuum Arc Remelting (VAR).

Optional Step 3- Vacuum Are Remelting (VAR).

FOllowing is chemical compostion of Invar 36,ALLOY 36,UNS K93600,NILO 36 forged steel rings

C .15 max

MN .60 max

P .006 max

S .004 max

Si .40 max

Cr .25 max

Ni 36.0 nom

Co .50 max

Fe bal

Following of Invar 36,ALLOY 36,UNS K93600,NILO 36 forging parts heat treatment mechanical property Delivery condition :

Rm - Tensile strength (MPa) (+AT) 490

Rp0.2 0.2% proof strength (MPa) (+AT) 240MPA

A - Min. elongation at fracture (%) longitud., (+AT) 42

All our forged Invar 36,ALLOY 36 forged parts will be done in following test

Tensile testing

Charpy Testing (-320°F to +350°F)

Hardness testing

Macro-etching

Non-Destructive Test Capabilities to Military and Commercial Standards (ASNT)

Level III / Test Examiner

Level II inspectors qualified to perform

Ultrasonic testing

Liquid penetrant inspection

Magnetic particle inspection

Dimensional/visual inspection

Metrology laboratory (dimensional)

Pyrometry laboratory (temperature)

Material certification to EN10204 Type 3.1 of finish Invar 36,ALLOY 36 forged material should be issued as per following

Material certificate,per batch,referred to this specification are issued by the manufacturershall include as minimum:

Order No.

Grade of material

Cast no.and heat treatment no.

Melting and refining process.

Certified chemical analysis.

Certified record of mechanical properties including impact test.

Certificate of Ultrasonic Test

Welcome your inquiry of Invar 36,ALLOY 36,UNS K93600,NILO 36forging forged steel parts