Description

Jiangsu Liangyi is professional manufacturer of 1.3974,X2CrNiMnMoNNb23-17-6-3,X2CrNiMnMoNNb231763,X2CrNiMnMoNNb23.17.6.3 open die forging parts and seamless rolled steel forged rings from china

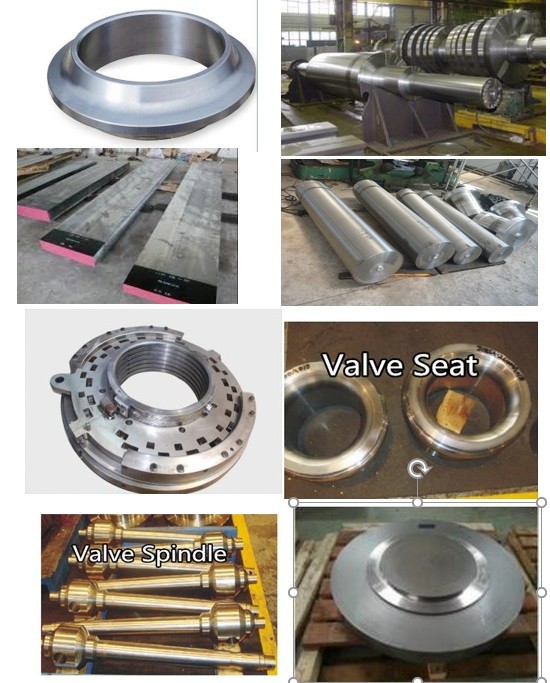

Following is the shape of 1.3974,X2CrNiMnMoNNb23-17-6-3,X2CrNiMnMoNNb231763,X2CrNiMnMoNNb23.17.6.3forging steel material that we could do is:X2CrNiMnMoNNb23-17-6-3 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X2CrNiMnMoNNb23.17.6.3Forged forging steel rings seamless rolled rings,1.3974 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.3974 Forged Forging Steel Discs Disks Blocks plates,X2CrNiMnMoNNb23-17-6-3 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.3974,X2CrNiMnMoNNb23-17-6-3,X2CrNiMnMoNNb231763,X2CrNiMnMoNNb23.17.6.3material that is used in following industry

X2CrNiMnMoNNb23-17-6-3 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X2CrNiMnMoNNb23.17.6.3Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.3974 Forged Forging ship boat Marine Propulsion Shafts Propeller Shaft

X2CrNiMnMoNNb23-17-6-3 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

1.3974 Forged Forging venturi cone meter Body Bodies Blocks

1.3974 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X2CrNiMnMoNNb23-17-6-3 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X2CrNiMnMoNNb23.17.6.3Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X2CrNiMnMoNNb23.17.6.3 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X2CrNiMnMoNNb23.17.6.3 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X2CrNiMnMoNNb23.17.6.3Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.3974 Forged Forging forge Steel transition Cone

1.3974 Forged Forging Steel Pressure Vessel Reactor Nozzles

X2CrNiMnMoNNb23-17-6-3 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.3974 is Non-magnetic special steel for shipbuilding, electrical engineering and mechanical engineering

Following is melting method for 1.3974 forged steel sleeves

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction meltingR.

FOllowing is chemical compostion of X2CrNiMnMoNNb23.17.6.3 forged steel rings

C max. 0,03

Si max. 1,00

Mn 4,50-6,50

P max. 0,025

S max. 0,010

Cr 21,00-24,50

Ni 15,50-18,00

Mo 2,80-3,40

N 0,30-0,50

Nb 0,10-0,30

W 0,10-0,30

The purity grade of the X2CrNiMnMoNNb23.17.6.3 forged steel material is to be determined per DIN 50602-K1.The following value is to be kept in this case(on 1000 mm²)-Sum characteristics value K1:≤2.0

For determination 4 tests per heat are to be employed at least Depending on the appearance of the analysed microsections also higher K1-Values may possibly be Tolerated.Content of Delta-Ferrite Delta ferrite content:<5% (Determined in a manner consistent with the evaluation technique described in ASTM E 45/Method A,"Worst Field Method"at V=100,specimen orientation:longitudinal.Thedistribution and size of delta ferrite must be such that it does not result in indication in magnetic particle testing of the ready-machined surface.)

Following of X2CrNiMnMoNNb23-17-6-3 forging parts heat treatment mechanical property Delivery condition :

Rm - Tensile strength (MPa) (+AT) 500MPA

Rp0.2 0.2% proof strength (MPa) (+AT) 185MPA

The following details shall be furnished in the test certificate of finished 1.3974,X2CrNiMnMoNNb23-17-6-3 round bars:

Heat No. , and melting type.

Dimensional inspection

Details of heat treatment cycle followed.

Results of chemical analysis including tramp elements.

Results of mechanical tests, including hardness test. All individual values shall be reported.Results of ultrasonic tests

Results of surface crack examination

Confirmation of the visual inspection

Confirmation of the verification inspection

Results of additional tests called for in the drawing/order.

Welcome your inquiry of 1.3974,X2CrNiMnMoNNb23-17-6-3,X2CrNiMnMoNNb231763,X2CrNiMnMoNNb23.17.6.3 forging forged steel parts

Following is the shape of 1.3974,X2CrNiMnMoNNb23-17-6-3,X2CrNiMnMoNNb231763,X2CrNiMnMoNNb23.17.6.3forging steel material that we could do is:X2CrNiMnMoNNb23-17-6-3 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X2CrNiMnMoNNb23.17.6.3Forged forging steel rings seamless rolled rings,1.3974 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.3974 Forged Forging Steel Discs Disks Blocks plates,X2CrNiMnMoNNb23-17-6-3 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.3974,X2CrNiMnMoNNb23-17-6-3,X2CrNiMnMoNNb231763,X2CrNiMnMoNNb23.17.6.3material that is used in following industry

X2CrNiMnMoNNb23-17-6-3 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X2CrNiMnMoNNb23.17.6.3Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.3974 Forged Forging ship boat Marine Propulsion Shafts Propeller Shaft

X2CrNiMnMoNNb23-17-6-3 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

1.3974 Forged Forging venturi cone meter Body Bodies Blocks

1.3974 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X2CrNiMnMoNNb23-17-6-3 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X2CrNiMnMoNNb23.17.6.3Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X2CrNiMnMoNNb23.17.6.3 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X2CrNiMnMoNNb23.17.6.3 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X2CrNiMnMoNNb23.17.6.3Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.3974 Forged Forging forge Steel transition Cone

1.3974 Forged Forging Steel Pressure Vessel Reactor Nozzles

X2CrNiMnMoNNb23-17-6-3 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.3974 is Non-magnetic special steel for shipbuilding, electrical engineering and mechanical engineering

Following is melting method for 1.3974 forged steel sleeves

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction meltingR.

FOllowing is chemical compostion of X2CrNiMnMoNNb23.17.6.3 forged steel rings

C max. 0,03

Si max. 1,00

Mn 4,50-6,50

P max. 0,025

S max. 0,010

Cr 21,00-24,50

Ni 15,50-18,00

Mo 2,80-3,40

N 0,30-0,50

Nb 0,10-0,30

W 0,10-0,30

The purity grade of the X2CrNiMnMoNNb23.17.6.3 forged steel material is to be determined per DIN 50602-K1.The following value is to be kept in this case(on 1000 mm²)-Sum characteristics value K1:≤2.0

For determination 4 tests per heat are to be employed at least Depending on the appearance of the analysed microsections also higher K1-Values may possibly be Tolerated.Content of Delta-Ferrite Delta ferrite content:<5% (Determined in a manner consistent with the evaluation technique described in ASTM E 45/Method A,"Worst Field Method"at V=100,specimen orientation:longitudinal.Thedistribution and size of delta ferrite must be such that it does not result in indication in magnetic particle testing of the ready-machined surface.)

Following of X2CrNiMnMoNNb23-17-6-3 forging parts heat treatment mechanical property Delivery condition :

Rm - Tensile strength (MPa) (+AT) 500MPA

Rp0.2 0.2% proof strength (MPa) (+AT) 185MPA

The following details shall be furnished in the test certificate of finished 1.3974,X2CrNiMnMoNNb23-17-6-3 round bars:

Heat No. , and melting type.

Dimensional inspection

Details of heat treatment cycle followed.

Results of chemical analysis including tramp elements.

Results of mechanical tests, including hardness test. All individual values shall be reported.Results of ultrasonic tests

Results of surface crack examination

Confirmation of the visual inspection

Confirmation of the verification inspection

Results of additional tests called for in the drawing/order.

Welcome your inquiry of 1.3974,X2CrNiMnMoNNb23-17-6-3,X2CrNiMnMoNNb231763,X2CrNiMnMoNNb23.17.6.3 forging forged steel parts