Description

Jiangsu Liangyi is professional manufacturer of Haynes Alloy 25/ Udimet L605/ Alloy L-605/AMS 5759/UNS R30605/Cobalt Alloy 25 open die forging parts and seamless rolled steel forged rings from china

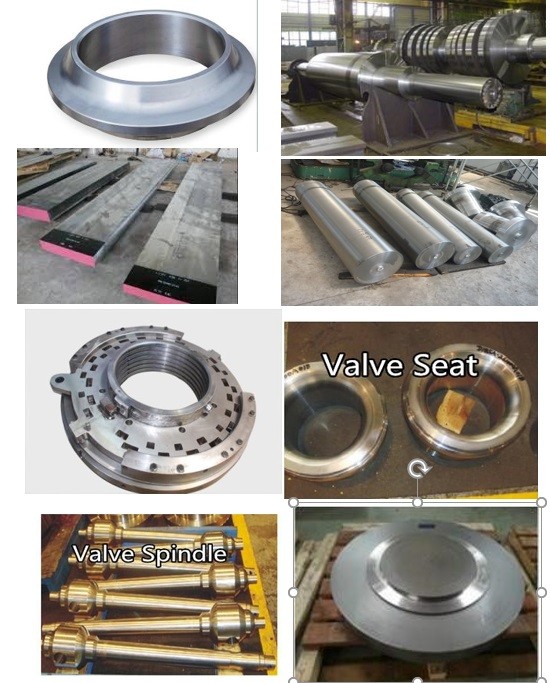

Following is the shape of Haynes Alloy 25/ Udimet L605/ Alloy L-605/AMS 5759/UNS R30605/Cobalt Alloy 25forging steel material that we could do is:Haynes Alloy 25 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Cobalt Alloy 25 Forged forging steel rings seamless rolled rings,Alloy L-605 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS R30605 Forged Forging Steel Discs Disks Blocks plates,Udimet L605/ Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Haynes Alloy 25/ Udimet L605/ Alloy L-605/AMS 5759/UNS R30605/Cobalt Alloy 25 material that is used in following industry

Haynes Alloy 25 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Udimet L605 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Alloy L-605 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Alloy L-605 forged forging bearings and bearing races rings

AMS 5759 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

UNS R30605 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Alloy L-605 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Haynes Alloy 25 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

Haynes Alloy 25 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

L-605 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

L-605 is non-magnetic cobalt based superalloy. HAYNES 25 (L605) maintains good strength upto 2150°F. AMS 5759 requires minimum yield strength of 45,000 psi at room temperature. HAYNES 25 (L605) maintains good oxidation resistance up to 1900° F. HAYNES 25 (L605) has a unique ability to resist corrosion in very severe environments. Highly resistant to hydrochloric acid, nitric acid and wet chlorine (subject to need for exercising care in its selection at certain con¬centrations and temperatures)

Alloy L-605 / Alloy 25 has many applications in military and commercial gas turbine engine components such as rings, blades and combustion chamber parts ,Gas turbine engine combustion chambers and afterburners,High temperature ball bearings and bearing races

Forgings Haynes Alloy 25 maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The hot working shall be done in such a way that a uniform fine grained microstructure is achieved.

The Haynes Alloy 25 forged material shall undergo the following heat treatment:

Annealing at 2150 °F to 2250 °F (1176 °C to 1232 °C)

Rapid air cooling or water quenching

The forgings Haynes Alloy 25 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of Haynes Alloy 25/ Udimet L605/ Alloy L-605/AMS 5759/UNS R30605/Cobalt Alloy 25 forging turbine parts is as

Carbon 0.05 – 0.15 %

Manganese 1.0 – 2.0 %

Silicon .40 % Max

Phosphorus 0.040 % Max

Sulfur 0.030 % Max

Chromium 19.0 – 21.0 %

Nickel 9.0 – 11.0 %

Tungsten 14.0 – 16.0 %

Iron 3.0 % Max

Cobalt Balance

mechanical property of for Haynes Alloy 25/ Udimet L605/ Alloy L-605/AMS 5759/UNS R30605/Cobalt Alloy 25 forged round bars is as follow

Tensile strength 125, 000 psi Min

Yield strength 45,000 psi Min

Elongation 30 % Min

.

All our Haynes Alloy 25/ Udimet L605/ Alloy L-605/AMS 5759/UNS R30605/Cobalt Alloy 25 forging steel products will have following inspection:

Chemical analyses

Mechanical analyse

UT testing according several norms

MPI testing

Spectral analyse

Hardness measurement according several methods

Tensile and bending tests

Impact test according several methods

Microscope investigation

Huey test

Interkristal corrosion test

Red white test

X-Ray test

3D dimensional check

Magnetic test

Dye penetrant test

Positive Alloy Material Identification (PAMI)

Magnetic particle test

Welcome your inquiry of Haynes Alloy 25/ Udimet L605/ Alloy L-605/AMS 5759/UNS R30605/Cobalt Alloy 25 forging parts