Description

Jiangsu Liangyi professional manufacturer of 1.6961,24NiCrMoV10-10,24NiCrMoV10.10,24NiCrMoV1010 open die forging parts and forged steel gas steam turbine turbine blade vane steel ,turbo generator,Turbomachines,Turbomachinery,turbogenerator forging steel turbine rotor shafts from china

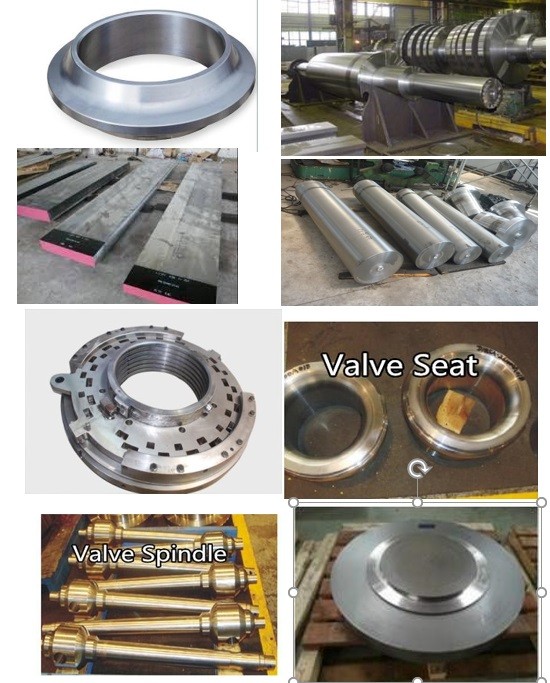

Following is the shape of 1.6961,24NiCrMoV10-10,24NiCrMoV10.10,24NiCrMoV1010 Forging steel material that we could do is:24NiCrMoV10-10 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, 1.6961 Forged forging steel rings seamless rolled rings, 24NiCrMoV10-10 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.6961 Forged Forging Steel Discs Disks Blocks plates, 24NiCrMoV1010 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings. 24NiCrMoV10.10 Forged Forging Steel Gas Steam Turbine Rotors Shafts,24NiCrMoV10-10 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars, 24NiCrMoV1010 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,24NiCrMoV10.10 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,24NiCrMoV10-10 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

,24NiCrMoV10-10 is Corrosion resistant high temperature martensitic steel normally used in in following gas steam turbine for Applications in the energy sector,Fossil,Coal-fired power plants,Gas

Our 1.6961,24NiCrMoV10-10 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

Chemical composition for 1.6961,24NiCrMoV10-10 forged steel gas turbine rotor shafts as follows

Carbon (C%)Min: 0,20 Max: 0,28

Manganese (Mn%) Min: 0,15 Max: 0,40

Silicon (Si%) ≤ 0,15

Phosphorus (P%)≤0,01

Sulfur (S%)≤0,007

Chrome (Cr%) Min: 2,00 Max: 2,60

Nickel (Ni%) Min: 2,00 Max: 2,80

Molybdenum (Mo%) Min: 0,50 Max: 0,80

Vanadium (V%) Min: 0,15 Max: 0,40

The following properties of 24NiCrMoV10-10 forging turbine blade flat bars at room temperature must be demonstrated by the following tests

Tensile strength, Rm: 900- 1050MPa

The yield point, Rp0,2: >780 MPa Properties of samples tested

longitudinally: Elongation, A:> 13%

Reduction > 40%

Charpy test :minimum 55J

24NiCrMoV10,10 forging steel turbine parts at elevated temperatures - the yield strength is as follows

Temperature 200℃ - Rp0,2: >700 MPa

Temperature 250℃ - Rp0,2: >680 MPa

Temperature 300℃ - Rp0,2: >670 MPa

Temperature 350℃ - Rp0,2: >650 MPa

Temperature 400℃ - Rp0,2: >620 MPa

Temperature 450℃ - Rp0,2: >580 MPa

Temperature 500℃ - Rp0,2: >550 MPa

We could produce forged steel 24NiCrMoV10-10 turbine rotor shafts in High,middle,low press steam turbine rotor,generator rotor, 35MW,50WM,60WM,70WM steam turbine rotor; 25X1M1%cA(P2MA)steam turbine

We have following Forging Equipments of make forging of 1.6961,24NiCrMoV10-10 forging steel parts, 4500t &850000t Hydraulic forging equipments; 50t&15t Manipulators; 2t&1t&450kg air hammer; 5t electro hydraulic hammer etc.

We have Heat treatment Equipments of make forged of 1.6961,24NiCrMoV10-10 forging turbine rotor shafts φ2*12m pit furnace; φ8*3*3m table resistor furnace; 1.5*0.8*1.5m box resistor furnace; 8*3*3m gas furnace; 6*3*2m gas furnace; 7.5*4*2.5 gas furnace;16*2.5*2.5 gas furnace etc.

Also we have following Machining Equipments of maching 1.6961,24NiCrMoV10-10 forged steel gas turbine rotor shafts, ; including φ2*12m heavy sleeper; φ5m vertical lathe; floor type boring and milling machine; CNC miller ;φ1.6*16m heavy sleeper; single-arm planer; boring and milling machine etc.