Description

Jiangsu Liangyi is professional manufacturer of 1.4449,X3CrNiMo18-12-3,X3CrNiMo18123,X3CrNiMo18.12.3 open die forging parts and seamless rolled steel forged rings from china

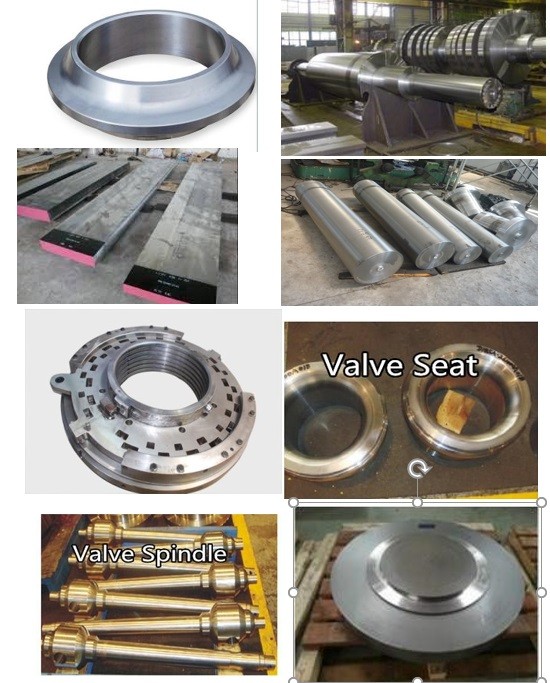

Following is the shape of 1.4449,X3CrNiMo18-12-3,X3CrNiMo18123,X3CrNiMo18.12.3 forging steel material that we could do is:X3CrNiMo18-12-3 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X3CrNiMo18.12.3 Forged forging steel rings seamless rolled rings,1.4449 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.4449 Forged Forging Steel Discs Disks Blocks plates,X3CrNiMo18-12-3 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4449,X3CrNiMo18-12-3,X3CrNiMo18123,X3CrNiMo18.12.3 material that is used in following industry

X3CrNiMo18-12-3 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X3CrNiMo18.12.3 Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.4449 Forged Forging Swept branches outlets steel fittings swept saddles

X3CrNiMo18-12-3 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

X3CrNiMo18.12.3 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

1.4449 Forged Forging venturi cone meter Body Bodies Blocks

1.4449 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X3CrNiMo18-12-3 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X3CrNiMo18-12-3 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

X3CrNiMo18.12.3 Forged Forging Steel double studded adapter flange

X3CrNiMo18.12.3 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X3CrNiMo18.12.3 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X3CrNiMo18.12.3 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X3CrNiMo18.12.3 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.4449 Forged Forging forge Steel transition Cone

1.4449 Forged Forging Steel Pressure Vessel Reactor Nozzles

X3CrNiMo18-12-3 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4449 is chrome-nickel austenitic alloy. It also contains molybdenum which increases general corrosion resistance, improves resistance to pitting from chloride ion solutions, the high levels of these elements persuade the alloy has better chloride pitting and general corrosion resistance to the conventional 304/304L and 316/316L grades.

Our X3CrNiMo18.12.3 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

FOllowing is production standard of 1.4449 forged parts

EN 10222-5: 2000 Steel forgings for pressure purposes. Martensitic, austenitic and austenitic-ferritic stainless steels

EN 10088-1: 2005 Stainless steels. List of stainless steels

FOllowing is chemical compostion of X3CrNiMo18.12.3 forged steel rings

C max 0.035

Si max 1

Mn max 2

Ni 11.5 - 12.5

P max 0.045

S max 0.015

Cr 17 - 18.2

Mo 2.25 - 2.27

N max 0.08

Cu max 1

Macrostructure of X3CrNiMo18-12-3 forging steel [arts is as follow

Visual examination of transverse full cross-sections X3CrNiMo18-12-3forged bars, billets, and stock for 1.4449 forging, X3CrNiMo18-12-3 forged rings, orextrusions, etched in hot hydrochloric acid in accordance with ASTM A 604, shall show no pipe or cracks. Porosity,segregation, inclusions, and other imperfections shall be no worse than the macrographs of ASTM A 604

- MACROSTRUCTURE LIMITS of 1.4449 forging materialis as follow

Class Condition Severity

1 Freckles A

2 White Spots A

3 Radial Segregation A

4 Ring Pattern B

Following of X3CrNiMo18-12-3 forging parts heat treatment mechanical property Delivery condition :

Rm - Tensile strength (MPa) (+AT) 520-720

Rp0.2 0.2% proof strength (MPa) (+AT) 220

KV - Impact energy (J) transverse, (+AT) +20°60 -196°60

KV - Impact energy (J) longitud., (+AT) +20°100

A - Min. elongation at fracture (%) longitud., (+AT) 45

We have following inspection equipment to inspection all our 1.4449,X3CrNiMo18-12-3 forging shafts

Tensile press

Charpy pendulum (up to – 90ºC)

Hardness testers

Scale

Thermometer

Spectrometer

Scales

Temperature control thermocouples

Continuous monitoring systems and process recording (heating, ring rolling and heat treatment)

Measuring laser

Pyrometer

Hardness testers

Laser measure

Comparators

Gauges

Micrometres

Bore gauges

UT equipment

MT equipment

Laser tracker

Fluorescent particles for liquid penetrant inspection

Radius gauges

Threaded plugs

Parallelism measuring devices

Roughness testers

Thickness gauges

Gauge blocks and rods

Light meters

Mass weight

Goniometers

Welcome your inquiry of 1.4449,X3CrNiMo18-12-3,X3CrNiMo18123,X3CrNiMo18.12.3 forging forged steel parts

Following is the shape of 1.4449,X3CrNiMo18-12-3,X3CrNiMo18123,X3CrNiMo18.12.3 forging steel material that we could do is:X3CrNiMo18-12-3 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X3CrNiMo18.12.3 Forged forging steel rings seamless rolled rings,1.4449 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.4449 Forged Forging Steel Discs Disks Blocks plates,X3CrNiMo18-12-3 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4449,X3CrNiMo18-12-3,X3CrNiMo18123,X3CrNiMo18.12.3 material that is used in following industry

X3CrNiMo18-12-3 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X3CrNiMo18.12.3 Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.4449 Forged Forging Swept branches outlets steel fittings swept saddles

X3CrNiMo18-12-3 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

X3CrNiMo18.12.3 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

1.4449 Forged Forging venturi cone meter Body Bodies Blocks

1.4449 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X3CrNiMo18-12-3 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X3CrNiMo18-12-3 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

X3CrNiMo18.12.3 Forged Forging Steel double studded adapter flange

X3CrNiMo18.12.3 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X3CrNiMo18.12.3 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X3CrNiMo18.12.3 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X3CrNiMo18.12.3 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.4449 Forged Forging forge Steel transition Cone

1.4449 Forged Forging Steel Pressure Vessel Reactor Nozzles

X3CrNiMo18-12-3 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4449 is chrome-nickel austenitic alloy. It also contains molybdenum which increases general corrosion resistance, improves resistance to pitting from chloride ion solutions, the high levels of these elements persuade the alloy has better chloride pitting and general corrosion resistance to the conventional 304/304L and 316/316L grades.

Our X3CrNiMo18.12.3 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

FOllowing is production standard of 1.4449 forged parts

EN 10222-5: 2000 Steel forgings for pressure purposes. Martensitic, austenitic and austenitic-ferritic stainless steels

EN 10088-1: 2005 Stainless steels. List of stainless steels

FOllowing is chemical compostion of X3CrNiMo18.12.3 forged steel rings

C max 0.035

Si max 1

Mn max 2

Ni 11.5 - 12.5

P max 0.045

S max 0.015

Cr 17 - 18.2

Mo 2.25 - 2.27

N max 0.08

Cu max 1

Macrostructure of X3CrNiMo18-12-3 forging steel [arts is as follow

Visual examination of transverse full cross-sections X3CrNiMo18-12-3forged bars, billets, and stock for 1.4449 forging, X3CrNiMo18-12-3 forged rings, orextrusions, etched in hot hydrochloric acid in accordance with ASTM A 604, shall show no pipe or cracks. Porosity,segregation, inclusions, and other imperfections shall be no worse than the macrographs of ASTM A 604

- MACROSTRUCTURE LIMITS of 1.4449 forging materialis as follow

Class Condition Severity

1 Freckles A

2 White Spots A

3 Radial Segregation A

4 Ring Pattern B

Following of X3CrNiMo18-12-3 forging parts heat treatment mechanical property Delivery condition :

Rm - Tensile strength (MPa) (+AT) 520-720

Rp0.2 0.2% proof strength (MPa) (+AT) 220

KV - Impact energy (J) transverse, (+AT) +20°60 -196°60

KV - Impact energy (J) longitud., (+AT) +20°100

A - Min. elongation at fracture (%) longitud., (+AT) 45

We have following inspection equipment to inspection all our 1.4449,X3CrNiMo18-12-3 forging shafts

Tensile press

Charpy pendulum (up to – 90ºC)

Hardness testers

Scale

Thermometer

Spectrometer

Scales

Temperature control thermocouples

Continuous monitoring systems and process recording (heating, ring rolling and heat treatment)

Measuring laser

Pyrometer

Hardness testers

Laser measure

Comparators

Gauges

Micrometres

Bore gauges

UT equipment

MT equipment

Laser tracker

Fluorescent particles for liquid penetrant inspection

Radius gauges

Threaded plugs

Parallelism measuring devices

Roughness testers

Thickness gauges

Gauge blocks and rods

Light meters

Mass weight

Goniometers

Welcome your inquiry of 1.4449,X3CrNiMo18-12-3,X3CrNiMo18123,X3CrNiMo18.12.3 forging forged steel parts