Description

Jiangsu Liangyi is professional manufacturer of Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 open die forging parts and seamless rolled steel forged rings from china

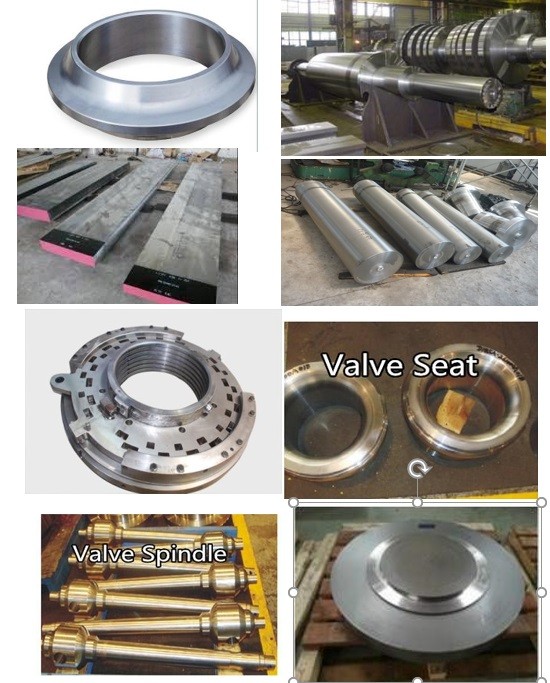

Following is the shape of Incoloy 27-7MO forging steel material that we could do is:Incoloy 27-7MO Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Incoloy 27-7MO Forged forging steel rings seamless rolled rings,Incoloy 27-7MO Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Incoloy 27-7MO Forged Forging Steel Discs Disks Blocks plates,Incoloy 27-7MO Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Incoloy 27-7MO material that is used in following industry

Incoloy 27-7MO forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

Incoloy 27-7MO Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Incoloy 27-7MO Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

Incoloy 27-7MO Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

Incoloy 27-7MO Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

Incoloy 27-7MO Forged Forging Steel nuclear Power

Alloy 27-7MO Forged Forging Steel Butterfly Valve Main Shafts Spindles

Incoloy 27-7MO Forged Forging Swept branches outlets steel fittings swept saddles

UNS S31277 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Incoloy 27-7MO Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Incoloy 27-7MO Forged Forging venturi cone meter Body Bodies Blocks

Incoloy 27-7MO Forged Forging Steel gate valves Body Bodies bespoke flat bars

Incoloy 27-7MO forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Alloy 27-7MO forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Incoloy 27-7MO Forged Forging Steel double studded adapter flange

Incoloy 27-7MO Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS S31277 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Incoloy 27-7MO Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Incoloy 27-7MO Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Incoloy 27-7MO Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Incoloy 27-7MO Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Incoloy 27-7MO Forged Forging forge Steel transition Cone

UNS S31277 Forged Forging Steel Pressure Vessel Reactor Nozzles

Alloy 27-7MO forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Incoloy 27-7MO is is an advanced 7% molybdenum super-austenitic stainless steel offering corrosion resistance in most environments superior to 6% molybdenum super-austenitic stainless steels. The alloy's content of nickel and nitrogen produce a stable austenitic structure. By virtue of its content of molybdenum, chromium, and nitrogen, alloy 27-7MO offers excellent resistance to pitting and crevice corrosion. The nickel, nitrogen, and molybdenum provide resistance to reducing media while a high content of chromium offers resistance to oxidizing media. Alloy 27-7MO performs well in mixed acid environments, especially those containing oxidizing and reducing acids. The alloy's contents of nickel and nitrogen result in resistance to stress corrosion cracking and attack by caustic media.

FOllowing is melting methods of Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 forged steel parts:

BEF / BEF + AOD / EAF, followed by electroslag refining (ESR or VAR ) if necessary for special purpose.

FOllowing is chemical compostion of Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 forged steel rings

Nickel ..........................................................................26.0-28.0

Chromium....................................................................20.5-23.0

Molybdenum ...................................................................6.5-8.0

Copper ............................................................................0.5-1.5

Nitrogen...........................................................................0.3-0.4

Iron ...............................................................................Balance*

Manganese .................................................................3.00 max.

Phosphorus ................................................................0.03 max.

Sulfur ..........................................................................0.01 max.

Silicon ...........................................................................0.5 max.

Carbon......................................................................0.020 max.

Following of Incoloy 27-7MO forging parts heat treatment nechanical property Delivery condition :

Tensile strength(annealed) 827 MPa 120 ksi

Yield strength(annealed) 414 MPa 60 ksi

Elongation at Break( in 2 in 50 mm) 50% 50%

Poissons Ratio 0.29 0.29

Modulus of Elasticity 138 GPa 20000 ksi

Hardness, Rockwell B 95 95

Hardness, Vickers (0% cold work) 225 225

Following is inspection standard of Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 forged pipes

ASTM A-370(Latest Edition): Test methods & Definitions for mechanical testing of steel products.

ASTM E8 (Latest Edition): Standard Test Methods for Tension Testing of Metallic Materials 2.8 ISO 6892-1(Latest Edition): Metallic Materials - Tensile Testing Part 1 Method Of Test AtRoom Temperature.

ISO 6506-1(Latest Edition): Metallic Materials - Brinell Hardness Test

ISO 6508-1(Latest Edition): Metallic Materials -- Rockwell Hardness Test

ISO 6507-1(Latest Edition): Metallic Materials -- Vickers Hardness Test

ASTM E10 (Latest Edition): Standard Test Method For Brinell Hardness Of Metallic Materials

ASTM E18 (Latest Edition): Standard Test Method For Rockwell Hardness Of Metallic Materials

ASTM E384 (Latest Edition): Standard Test Method For Knoop & Vickers Hardness Of Metallic Materials

ASTM A-388/388M (Latest Edition): Specification for Ultrasonic Examination of heavy steel Forgings.

ASTM E 415(Latest Edition): Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission Spectrometry

ASTM A751 (Latest Edition): Standard Test Methods And Practices For Chemical Analysis Of Steel Product

ASTM E1086 (Latest Edition): Standard Test Method for Analysis of Austenitic Stainless Steel by Spark Atomic Emission Spectrometry

ASTM E23 (Latest Edition): Standard Test Method For Notched Bar Impact Testing Of Metallic Materials

INSP/MSC/10 (Latest Revision): Procedure for Visual Examination

HTQR/MSC/01 (Latest Revision): Heat Treatment Equipment Qualification Requirement

ASTM E2375 (Latest Revision): Standard Practice for Ultrasonic Testing of Wrought Products

ASTM E127 (Latest Revision): Standard Practice for Fabrication and Control of Flat Bottomed Hole Ultrasonic Standard Reference Blocks

ASTM E428 (Latest Revision): Standard Practice for Fabrication and Control of metal, other than aluminum, reference block used in Ultrasonic Testing

Marking of finished Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 forged parts

Unless otherwise indicated in the drawing or in the part specification, marking with serial number shall be carried out by mean of stamping according to clients technical manual following provisions indicated on the part dr awing.

The following marking shall be applied before removing any material from the forging:

• name or trademark of manufacturer of the forging;

• serial number of the forging of origin

• position from which the piece is removed with reference to the part specification.

Welcome your inquiry of Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 forging forged steel parts

Following is the shape of Incoloy 27-7MO forging steel material that we could do is:Incoloy 27-7MO Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Incoloy 27-7MO Forged forging steel rings seamless rolled rings,Incoloy 27-7MO Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Incoloy 27-7MO Forged Forging Steel Discs Disks Blocks plates,Incoloy 27-7MO Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Incoloy 27-7MO material that is used in following industry

Incoloy 27-7MO forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

Incoloy 27-7MO Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Incoloy 27-7MO Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

Incoloy 27-7MO Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

Incoloy 27-7MO Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

Incoloy 27-7MO Forged Forging Steel nuclear Power

Alloy 27-7MO Forged Forging Steel Butterfly Valve Main Shafts Spindles

Incoloy 27-7MO Forged Forging Swept branches outlets steel fittings swept saddles

UNS S31277 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Incoloy 27-7MO Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Incoloy 27-7MO Forged Forging venturi cone meter Body Bodies Blocks

Incoloy 27-7MO Forged Forging Steel gate valves Body Bodies bespoke flat bars

Incoloy 27-7MO forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Alloy 27-7MO forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Incoloy 27-7MO Forged Forging Steel double studded adapter flange

Incoloy 27-7MO Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS S31277 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Incoloy 27-7MO Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Incoloy 27-7MO Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Incoloy 27-7MO Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Incoloy 27-7MO Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Incoloy 27-7MO Forged Forging forge Steel transition Cone

UNS S31277 Forged Forging Steel Pressure Vessel Reactor Nozzles

Alloy 27-7MO forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Incoloy 27-7MO is is an advanced 7% molybdenum super-austenitic stainless steel offering corrosion resistance in most environments superior to 6% molybdenum super-austenitic stainless steels. The alloy's content of nickel and nitrogen produce a stable austenitic structure. By virtue of its content of molybdenum, chromium, and nitrogen, alloy 27-7MO offers excellent resistance to pitting and crevice corrosion. The nickel, nitrogen, and molybdenum provide resistance to reducing media while a high content of chromium offers resistance to oxidizing media. Alloy 27-7MO performs well in mixed acid environments, especially those containing oxidizing and reducing acids. The alloy's contents of nickel and nitrogen result in resistance to stress corrosion cracking and attack by caustic media.

FOllowing is melting methods of Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 forged steel parts:

BEF / BEF + AOD / EAF, followed by electroslag refining (ESR or VAR ) if necessary for special purpose.

FOllowing is chemical compostion of Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 forged steel rings

Nickel ..........................................................................26.0-28.0

Chromium....................................................................20.5-23.0

Molybdenum ...................................................................6.5-8.0

Copper ............................................................................0.5-1.5

Nitrogen...........................................................................0.3-0.4

Iron ...............................................................................Balance*

Manganese .................................................................3.00 max.

Phosphorus ................................................................0.03 max.

Sulfur ..........................................................................0.01 max.

Silicon ...........................................................................0.5 max.

Carbon......................................................................0.020 max.

Following of Incoloy 27-7MO forging parts heat treatment nechanical property Delivery condition :

Tensile strength(annealed) 827 MPa 120 ksi

Yield strength(annealed) 414 MPa 60 ksi

Elongation at Break( in 2 in 50 mm) 50% 50%

Poissons Ratio 0.29 0.29

Modulus of Elasticity 138 GPa 20000 ksi

Hardness, Rockwell B 95 95

Hardness, Vickers (0% cold work) 225 225

Following is inspection standard of Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 forged pipes

ASTM A-370(Latest Edition): Test methods & Definitions for mechanical testing of steel products.

ASTM E8 (Latest Edition): Standard Test Methods for Tension Testing of Metallic Materials 2.8 ISO 6892-1(Latest Edition): Metallic Materials - Tensile Testing Part 1 Method Of Test AtRoom Temperature.

ISO 6506-1(Latest Edition): Metallic Materials - Brinell Hardness Test

ISO 6508-1(Latest Edition): Metallic Materials -- Rockwell Hardness Test

ISO 6507-1(Latest Edition): Metallic Materials -- Vickers Hardness Test

ASTM E10 (Latest Edition): Standard Test Method For Brinell Hardness Of Metallic Materials

ASTM E18 (Latest Edition): Standard Test Method For Rockwell Hardness Of Metallic Materials

ASTM E384 (Latest Edition): Standard Test Method For Knoop & Vickers Hardness Of Metallic Materials

ASTM A-388/388M (Latest Edition): Specification for Ultrasonic Examination of heavy steel Forgings.

ASTM E 415(Latest Edition): Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission Spectrometry

ASTM A751 (Latest Edition): Standard Test Methods And Practices For Chemical Analysis Of Steel Product

ASTM E1086 (Latest Edition): Standard Test Method for Analysis of Austenitic Stainless Steel by Spark Atomic Emission Spectrometry

ASTM E23 (Latest Edition): Standard Test Method For Notched Bar Impact Testing Of Metallic Materials

INSP/MSC/10 (Latest Revision): Procedure for Visual Examination

HTQR/MSC/01 (Latest Revision): Heat Treatment Equipment Qualification Requirement

ASTM E2375 (Latest Revision): Standard Practice for Ultrasonic Testing of Wrought Products

ASTM E127 (Latest Revision): Standard Practice for Fabrication and Control of Flat Bottomed Hole Ultrasonic Standard Reference Blocks

ASTM E428 (Latest Revision): Standard Practice for Fabrication and Control of metal, other than aluminum, reference block used in Ultrasonic Testing

Marking of finished Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 forged parts

Unless otherwise indicated in the drawing or in the part specification, marking with serial number shall be carried out by mean of stamping according to clients technical manual following provisions indicated on the part dr awing.

The following marking shall be applied before removing any material from the forging:

• name or trademark of manufacturer of the forging;

• serial number of the forging of origin

• position from which the piece is removed with reference to the part specification.

Welcome your inquiry of Incoloy 27-7MO,Alloy 27-7MO,UNS S31277 forging forged steel parts