Description

Jiangsu Liangyi professional manufacturer of 1.4901,X10CrWMoVNb9-2,X10CrWMoVNb9.2,X10CrWMoVNb92,X10 CrWMoVNb 9-2 open die forging parts and seamless rolled steel forged rings,forged pipes tubes,forging steel valve body valve closure valve stems valve bonnet valve body valve seat rings from china

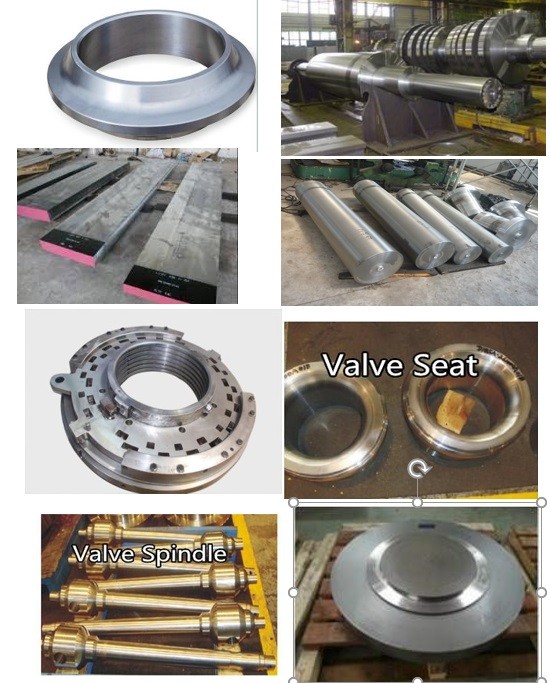

Following is the shape of 1.4901,X10CrWMoVNb9-2,X10CrWMoVNb9.2,X10CrWMoVNb92,X10 CrWMoVNb 9-2 forging steel material that we could do is:1.4901 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X10CrWMoVNb9-2 Forged forging steel rings seamless rolled rings,X10CrWMoVNb92 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X10CrWMoVNb9.2 Forged Forging Steel Discs Disks Blocks plates,X10 CrWMoVNb 9-2 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4901,X10CrWMoVNb9-2 that is used in following industry

1.4901,X10CrWMoVNb9-2 forged steel valve body,valve bonnet.valve closure, valve seat rings, valve stems, valve discs disks for High pressure gate valves,High pressure globe valves, High Pressure Swing Check valve,High pressure valves steam turbine power valves, GAs TURBINE BYPASS VALVE,Line blind valves,Preheater bypass valve

1.4901 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel

X10CrWMoVNb9-2 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

X10CrWMoVNb92 Forging Forged Steel Gas Turbine Wheels Discs turbine impeller turbine blisks

X10CrWMoVNb9.2 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

X10CrWMoVNb9.2 is Among wrought stainless steels, the composition of EN 1.4901 stainless steel is notable for including zirconium (Zr) and boron (B). Zirconium is used to improve ductility and oxidation resistance. Boron is used to improve hardenability. It has a substantial effect when added in even tiny amounts. It is an improved version of the P91 / T91 / F91 material with a 2% addition of Tungsten, a slightly increased amount of Chromium, and a reduced content of Molybdenum, characterized by a creep resistance at temperatures of up to 600C higher by about 1/3. The material has even higher corrosion resistance and weldability. It is used at the highest operating temperatures up to 650C.Grade 91/92 - Steel used for production of boiler components with supercritical and ultra-critical parameters - jackets, connectors for steam superheater outlet chambers, superheated steam superheaters,X10CrWMoVNb9.2 forging turbine shaft parts, X10CrWMoVNb9-2 forging steel chambers and pipelines for fresh and superheated steam, superheater coils, steam collectors, outlet collectors, fittings and sleeves for the installation of boilers, connectors, pipelines of modern power units operating at temperatures of approximately 550-640C and steam pressures of approx. 18-30 MPa.

FOllowing is melting methods of 1.4901,X10CrWMoVNb9-2 forged stee parts:IFF, LF, EAF + VD + LF followed by electroslag refining (ESR) if necessary for special purpose.

All our 1.4901,X10CrWMoVNb9-2 forging steel rings can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

FOllowing is chemical compostion of 1.4901,X10CrWMoVNb9-2 forging shells

Iron (Fe) 85.8 to 89.1

Chromium (Cr) 8.5 to 9.5

Tungsten (W) 1.5 to 2.0

Molybdenum (Mo) 0.3 to 0.6

Manganese (Mn) 0.3 to 0.6

Silicon (Si) 0 to 0.5

Vanadium (V) 0.15 to 0.25

Nickel (Ni) 0 to 0.4

Carbon (C) 0.070 to 0.13

Niobium (Nb) 0.040 to 0.090

Nitrogen (N) 0.030 to 0.070

Phosphorus (P) 0 to 0.020

Aluminum (Al) 0 to 0.020

Sulfur (S) 0 to 0.010

Titanium (Ti) 0 to 0.010

Zirconium (Zr) 0 to 0.010

Boron (B) 0.0010 to 0.0060

FOllowing is mechanical property for 1.4901,X10CrWMoVNb9-2 forging steel pipes

Rm - Tensile strength (MPa) (+NT) 620-850

Rp0.2 0.2% proof strength (MPa) (+NT) Min 440

KV - Impact energy (J) longitud., (+NT) +20° min 40

KV - Impact energy (J) transverse, (+NT) +20° min 27

A - Min. elongation at fracture (%) longitud., (+NT) min 19

A - Min. elongation at fracture (%) transverse, (+NT) min 17

The quality of Jiangsu products 1.4901,X10CrWMoVNb9-2 forging workshop is based on its “state-of-the-art”technology of its laboratories for metallurgy and chemistry. we perform

a range of tests, including mechanical property tests, chemical and environmental analyses, metallographic, macrographic and micrographic tests using optical and electronic microscopes.

, all 1.4901 forging steel turbine rotor shafts materials are tested and certified in accordance with nternational standards and Customer’s specifications, using any combination of the following methods: UT-RT-HT-PT-MT-VT-DT