Description

Jiangsu Liangyi is professional manufacturer of ASTM A182 Grade F44,A182-F44 ,F44 ,ASTM A 182 F 44 open die forging parts and seamless rolled steel forged rings from china

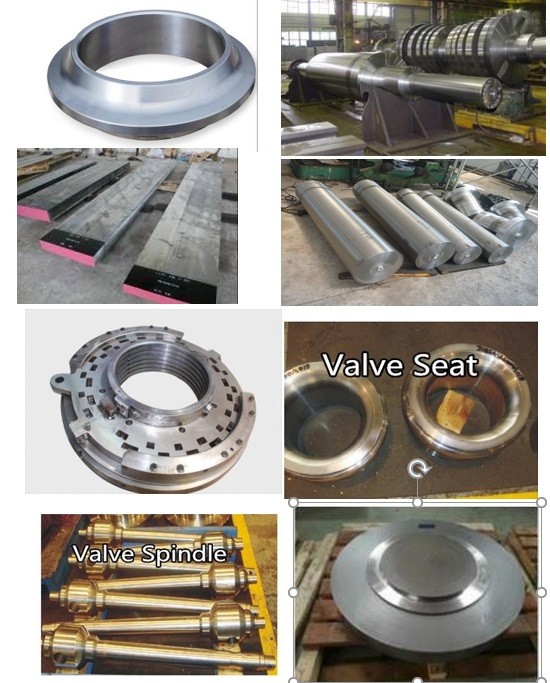

Following is the shape of ASTM A182 Grade F44,A182-F44 ,F44 ,ASTM A 182 F 44 forging steel material that we could do is:A182-F44 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,ASTM A 182 F 44 Forged forging steel rings seamless rolled rings,ASTM A182 Grade F44 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,ASTM A182 Grade F44 Forged Forging Steel Discs Disks Blocks plates,A182-F44 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of ASTM A182 Grade F44,A182-F44 ,F44 ,ASTM A 182 F 44 material that is used in following industry

ASTM A 182 F 44 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

ASTM A182 Grade F44 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

ASTM A 182 F 44 Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

ASTM A182 Grade F44 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

A182-F44 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ASTM A182 Grade F44 Forged Forging Steel nuclear Power

ASTM A 182 F 44 Forged Forging Steel Butterfly Valve Main Shafts Spindles

ASTM A182 Grade F44 Forged Forging Swept branches outlets steel fittings swept saddles

A182-F44 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

ASTM A 182 F 44 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

ASTM A182 Grade F44 Forged Forging venturi cone meter Body Bodies Blocks

ASTM A182 Grade F44 Forged Forging Steel gate valves Body Bodies bespoke flat bars

A182-F44 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

A182-F44 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

ASTM A 182 F 44 Forged Forging Steel double studded adapter flange

ASTM A 182 F 44 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

ASTM A182 Grade F44 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

ASTM A 182 F 44 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

ASTM A 182 F 44 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

ASTM A 182 F 44 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

ASTM A 182 F 44 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

ASTM A182 Grade F44 Forged Forging forge Steel transition Cone

ASTM A182 Grade F44 Forged Forging Steel Pressure Vessel Reactor Nozzles

A182-F44 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

A182-F44 is described as a 6% Mo super austenitic stainless steel. The steel combines moderate mechanical strength (typically over 300 MPa yield strength) and high ductility with excellent corrosion resistance in seawater and a variety of industrial environments. Typically the alloy has a PREn (Pitting Resistance Equivalent) of 42-44 which ensures that the resistance to pitting corrosion is high. In addition, the steel provides good resistance to crevice corrosion. Ambient and subzero temperature notch ductility is very good.

FOllowing is chemical compostion of ASTM A 182 F 44 forged steel rings

Carbon C 0,020

Manganese Mn 1,00

Phosphorus P 0,030

Sulfur S 0,015

Silicon Si 0,80

Nickel Ni 17,5-18,5

Chrome Cr 19,5-20,5

Molybdenum Mo 6,0-6,5

Nitrogen N 0,18-0,22

Copper Cu 0,50-1,00

Following of A182-F44 forging parts heat treatment nechanical property Delivery condition :

Ultimate Tensile Strength 650 – 850 MPa ( 94 – 123 ksi )

0.2% Proof Strength 300 MPa ( 44 ksi )

Elongation 35 %

Hardness (Max) 260 HB

Impact 100 J ( 74 ft.lb )

Qualification of manufacturing procedure of ASTM A182 Grade F44 forging parts

The Manufacturing Process Plan (MPP) shall be submitted to the approval of clients Material

& Process Engineering dept. clients before qualification procedure begins. It shall detail at least

the following:

• type of ingot (supplier, manufacturing process, dimensions, and tests to beperformed);

• forging process;

• heat treatment process;

• tests on component.

In general, dissection of the first piece within the terms detailed in the part specification is required.

This activity may be omitted, upon decision of clients, if the supplier has already proven to be able to successfully produce components of similar shape, dimensions and manufacturing

process.

We have following inspection equipment to inspect of all our ASTM A182 Grade F44 forging steel parts

a well equipped chemical lab which carries out test analysis on the steel heats made in the steel mill

a well equipped lab which carries out mechanical tensile & resilience tests as well as creep tests

a metallurgic lab for structural macro-micro and inclusion micro metallurgic examinations, according to ISO 17025

non destructive UT/MP/LP tests carried out by experienced and qualified SNT-TA-1A operators

fixed and portable Brinell/3000/10 hardness check equipment

dedicated and certified equipment for dimensional controls.

Material certification to EN10204 Type 3.1 of finishe ASTM A182 Grade F44 forged material should be issued as per following

Material certificate,per batch,referred to this specification are issued by the manufacturershall include as minimum:

Order No.

Grade of material

Cast no.and heat treatment no.

Melting and refining process.

Certified chemical analysis.

Certified record of mechanical properties including impact test.

Certificate of Ultrasonic Test

Material certification must include a statement that material meets the requirements of NACE MR0175.Calibration of heat treatment furnaces and the Equivalent Round of the Qualification test coupon comply with API Spec 6A

Welcome your inquiry of ASTM A182 Grade F44,A182-F44 ,F44 ,ASTM A 182 F 44 forging forged steel parts

Following is the shape of ASTM A182 Grade F44,A182-F44 ,F44 ,ASTM A 182 F 44 forging steel material that we could do is:A182-F44 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,ASTM A 182 F 44 Forged forging steel rings seamless rolled rings,ASTM A182 Grade F44 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,ASTM A182 Grade F44 Forged Forging Steel Discs Disks Blocks plates,A182-F44 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of ASTM A182 Grade F44,A182-F44 ,F44 ,ASTM A 182 F 44 material that is used in following industry

ASTM A 182 F 44 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

ASTM A182 Grade F44 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

ASTM A 182 F 44 Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

ASTM A182 Grade F44 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

A182-F44 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ASTM A182 Grade F44 Forged Forging Steel nuclear Power

ASTM A 182 F 44 Forged Forging Steel Butterfly Valve Main Shafts Spindles

ASTM A182 Grade F44 Forged Forging Swept branches outlets steel fittings swept saddles

A182-F44 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

ASTM A 182 F 44 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

ASTM A182 Grade F44 Forged Forging venturi cone meter Body Bodies Blocks

ASTM A182 Grade F44 Forged Forging Steel gate valves Body Bodies bespoke flat bars

A182-F44 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

A182-F44 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

ASTM A 182 F 44 Forged Forging Steel double studded adapter flange

ASTM A 182 F 44 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

ASTM A182 Grade F44 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

ASTM A 182 F 44 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

ASTM A 182 F 44 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

ASTM A 182 F 44 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

ASTM A 182 F 44 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

ASTM A182 Grade F44 Forged Forging forge Steel transition Cone

ASTM A182 Grade F44 Forged Forging Steel Pressure Vessel Reactor Nozzles

A182-F44 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

A182-F44 is described as a 6% Mo super austenitic stainless steel. The steel combines moderate mechanical strength (typically over 300 MPa yield strength) and high ductility with excellent corrosion resistance in seawater and a variety of industrial environments. Typically the alloy has a PREn (Pitting Resistance Equivalent) of 42-44 which ensures that the resistance to pitting corrosion is high. In addition, the steel provides good resistance to crevice corrosion. Ambient and subzero temperature notch ductility is very good.

FOllowing is chemical compostion of ASTM A 182 F 44 forged steel rings

Carbon C 0,020

Manganese Mn 1,00

Phosphorus P 0,030

Sulfur S 0,015

Silicon Si 0,80

Nickel Ni 17,5-18,5

Chrome Cr 19,5-20,5

Molybdenum Mo 6,0-6,5

Nitrogen N 0,18-0,22

Copper Cu 0,50-1,00

Following of A182-F44 forging parts heat treatment nechanical property Delivery condition :

Ultimate Tensile Strength 650 – 850 MPa ( 94 – 123 ksi )

0.2% Proof Strength 300 MPa ( 44 ksi )

Elongation 35 %

Hardness (Max) 260 HB

Impact 100 J ( 74 ft.lb )

Qualification of manufacturing procedure of ASTM A182 Grade F44 forging parts

The Manufacturing Process Plan (MPP) shall be submitted to the approval of clients Material

& Process Engineering dept. clients before qualification procedure begins. It shall detail at least

the following:

• type of ingot (supplier, manufacturing process, dimensions, and tests to beperformed);

• forging process;

• heat treatment process;

• tests on component.

In general, dissection of the first piece within the terms detailed in the part specification is required.

This activity may be omitted, upon decision of clients, if the supplier has already proven to be able to successfully produce components of similar shape, dimensions and manufacturing

process.

We have following inspection equipment to inspect of all our ASTM A182 Grade F44 forging steel parts

a well equipped chemical lab which carries out test analysis on the steel heats made in the steel mill

a well equipped lab which carries out mechanical tensile & resilience tests as well as creep tests

a metallurgic lab for structural macro-micro and inclusion micro metallurgic examinations, according to ISO 17025

non destructive UT/MP/LP tests carried out by experienced and qualified SNT-TA-1A operators

fixed and portable Brinell/3000/10 hardness check equipment

dedicated and certified equipment for dimensional controls.

Material certification to EN10204 Type 3.1 of finishe ASTM A182 Grade F44 forged material should be issued as per following

Material certificate,per batch,referred to this specification are issued by the manufacturershall include as minimum:

Order No.

Grade of material

Cast no.and heat treatment no.

Melting and refining process.

Certified chemical analysis.

Certified record of mechanical properties including impact test.

Certificate of Ultrasonic Test

Material certification must include a statement that material meets the requirements of NACE MR0175.Calibration of heat treatment furnaces and the Equivalent Round of the Qualification test coupon comply with API Spec 6A

Welcome your inquiry of ASTM A182 Grade F44,A182-F44 ,F44 ,ASTM A 182 F 44 forging forged steel parts