Description

Jiangsu Liangyi is professional manufacturer of AMS 5891,AMS5891 open die forging parts and seamless rolled steel forged rings from china

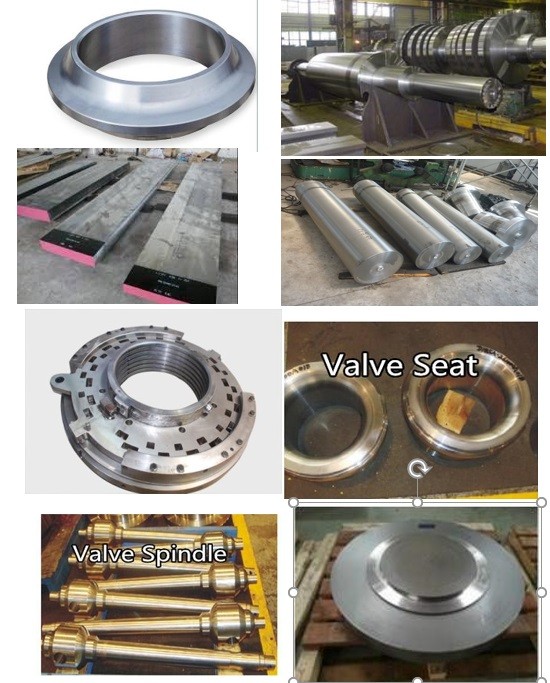

Following is the shape of AMS 5891 forging steel material that we could do is:AMS 5891 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Haynes AMS 5891 Forged forging steel rings seamless rolled rings,AMS 5891 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5891 Forged Forging Steel Discs Disks Blocks plates,AMS 5891 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5891 material that is used in following industry

AMS 5891 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5891 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AMS 5891 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

AMS 5891 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5891 Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields

AMS 5891 Forged Forging Rolled Steel Gas Steam Turbine shrouds

AMS 5891 forging forged steel tube sheets, baffle plates, nozzles,flanges for heat exchanger

AMS 5891 material for furnace retorts, chains and fixtures, burner flame shrouds, recuperator internals, dampers, nitriding furnace internals, heat-treating baskets, grates, trays, sparger tubes, thermocouple protection tubes, cyclone internals

AMS 5891 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5891 forged forging hot working dies,tooling, die blocks,mould, mold.

AMS 5891 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

AMS 5891 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5891 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5891 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5891 is nickel-chromium and tungsten is another in the family of high temperature oxidation resistant, high strength alloys. It may be utilized effectively at temperatures up to 2100 F.

AMS 5891 is widely used in Gas turbine hot section components such as combustion cans, thermocouple protection tubes, heat exchangers and industrial furnace fixtures and muffles.

The AMS 5891 forged material shall undergo the following heat treatment:

Solution Treatment - 1080 °C (1975 °F) for 8 hours + air cool or oil/ water quench

Precipitation Heat Treatment (As per BS HR2) - 700 °C (12230 °F) for 16 hours + air cool

Chemical composition of AMS 5891 forging turbine parts is as

Aluminum0.2 - 0.5

Boron 0.015 max

Carbon 0.05 - 0.15

Chromium 20 - 24

Cobalt 5 max

Iron 3 max

Lanthium 0.005 - 0.05

Manganese 0.3 - 1

Molybdenum 1 - 3

Nickel Balance

Phosphorus 0.03 max

Silicon 0.25 - 0.75

Sulphur 0.015 max

Tungsten 13 - 15

mechanical property of for AMS 5891 forged round bars is as follow

Properties Metric Imperial

Tensile strength 485 MPa 70300 psi

Yield strength 275 MPa 39900 psi

Elongation at break 15.0 % 15.0 %

All our AMS 5891 forging rings is melting by ESR+VIR or VIM+ESR+VAR

All our AMS 5891 forging parts can be release en10204-3.1 certificate, or en10204-3.2 inspection certificate from following third party,3.2 mit TUV ,GL (Germanischer Lloyd),BV (Bureau Veritas),DNV (Det Norske Veritas),ABS (American Bureau of Shipping),Lloyds Register of Shipping, RMRS (Russian Maritime Register of Shipping),RINA (Registro Italiano Navale)

For Every pieces of AMS 5891 forging round bars, we could do following testing Non destructive tests such as visual, dimensional, ultrasonic testing,dye penetrant testing , Magnetic particle test(MPl), the mirrostructure and technological tests such as tensile, resilience, creep tests, hardness,Metallographic exams,Chemical analysis

Welcome your inquiry of AMS 5891 forging parts

Following is the shape of AMS 5891 forging steel material that we could do is:AMS 5891 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Haynes AMS 5891 Forged forging steel rings seamless rolled rings,AMS 5891 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5891 Forged Forging Steel Discs Disks Blocks plates,AMS 5891 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5891 material that is used in following industry

AMS 5891 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5891 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AMS 5891 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

AMS 5891 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5891 Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields

AMS 5891 Forged Forging Rolled Steel Gas Steam Turbine shrouds

AMS 5891 forging forged steel tube sheets, baffle plates, nozzles,flanges for heat exchanger

AMS 5891 material for furnace retorts, chains and fixtures, burner flame shrouds, recuperator internals, dampers, nitriding furnace internals, heat-treating baskets, grates, trays, sparger tubes, thermocouple protection tubes, cyclone internals

AMS 5891 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5891 forged forging hot working dies,tooling, die blocks,mould, mold.

AMS 5891 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

AMS 5891 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5891 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5891 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5891 is nickel-chromium and tungsten is another in the family of high temperature oxidation resistant, high strength alloys. It may be utilized effectively at temperatures up to 2100 F.

AMS 5891 is widely used in Gas turbine hot section components such as combustion cans, thermocouple protection tubes, heat exchangers and industrial furnace fixtures and muffles.

The AMS 5891 forged material shall undergo the following heat treatment:

Solution Treatment - 1080 °C (1975 °F) for 8 hours + air cool or oil/ water quench

Precipitation Heat Treatment (As per BS HR2) - 700 °C (12230 °F) for 16 hours + air cool

Chemical composition of AMS 5891 forging turbine parts is as

Aluminum0.2 - 0.5

Boron 0.015 max

Carbon 0.05 - 0.15

Chromium 20 - 24

Cobalt 5 max

Iron 3 max

Lanthium 0.005 - 0.05

Manganese 0.3 - 1

Molybdenum 1 - 3

Nickel Balance

Phosphorus 0.03 max

Silicon 0.25 - 0.75

Sulphur 0.015 max

Tungsten 13 - 15

mechanical property of for AMS 5891 forged round bars is as follow

Properties Metric Imperial

Tensile strength 485 MPa 70300 psi

Yield strength 275 MPa 39900 psi

Elongation at break 15.0 % 15.0 %

All our AMS 5891 forging rings is melting by ESR+VIR or VIM+ESR+VAR

All our AMS 5891 forging parts can be release en10204-3.1 certificate, or en10204-3.2 inspection certificate from following third party,3.2 mit TUV ,GL (Germanischer Lloyd),BV (Bureau Veritas),DNV (Det Norske Veritas),ABS (American Bureau of Shipping),Lloyds Register of Shipping, RMRS (Russian Maritime Register of Shipping),RINA (Registro Italiano Navale)

For Every pieces of AMS 5891 forging round bars, we could do following testing Non destructive tests such as visual, dimensional, ultrasonic testing,dye penetrant testing , Magnetic particle test(MPl), the mirrostructure and technological tests such as tensile, resilience, creep tests, hardness,Metallographic exams,Chemical analysis

Welcome your inquiry of AMS 5891 forging parts