Description

Jiangsu Liangyi professional manufacturer of 25Х1М1ФA,25Ch1M1F,21Kh1M1F,25Х1М1Ф open die forging parts and seamless rolled steel forged rings,forged pipes tubes, 25Ch1M1F forged forging steel gas steam turbine blade bolts rotor shafts from china

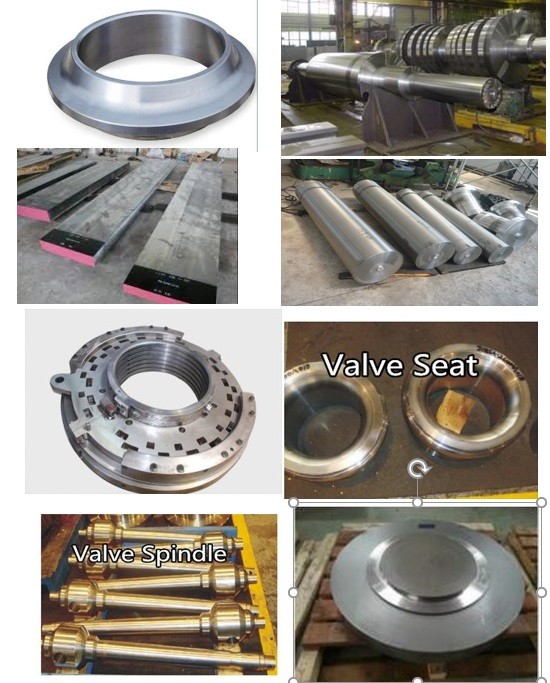

Following is the shape of 25Х1М1ФA,25Ch1M1F,21Kh1M1F,25Х1М1Ф forging steel material that we could do is:25Ch1M1F Forged Steel round bars square bars Flat bars Rectangles Bars Rods,25Х1М1Ф Forged forging steel rings seamless rolled rings,21Kh1M1F Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,21Kh1M1F Forged Forging Steel Discs Disks Blocks plates,25Х1М1Ф Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 25Х1М1ФA,25Ch1M1F,21Kh1M1F,25Х1М1Ф that is used in following industry

25Х1М1Ф forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

21Kh1M1F Forged Forging Gas steam turbine rotor shafts

25Х1М1Ф Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs, turbine wheels

25Х1М1ФA Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

25Х1М1ФA is high temperature boiler steels for energy industries. They are used in the production of components/subassemblies for the power industry, working at the temperatures up to 550 oC for small parts and for large forgings. The main applications of these grades of steel are rotors of steam turbines, rotor blades, shaft forgings, reservoirs and covers for up to 550 ℃ temperatures, nuts, tubes for high temperatures up to 540 ℃.

The production standard of 25Х1М1ФA forging steel pipes is as follows

ГОСТ 8479-70; ГОСТ 2591-2006; ГОСТ 1133-71; ГОСТ 2590-2006;ГОСТ 103-2006; ГОСТ 20072-74; ГОСТ 14955-77; ГОСТ 7417-75; ГОСТ 1051-73; ГОСТ 8559-75; ГОСТ 8560-78; ГОСТ 4405-75

FOllowing is chemical compostion of 25Ch1M1F,21Kh1M1F,25Х1М1Ф forged steel parts

C 0.22 - 0.29

Si 0.17 - 0.37

Mn 0.4 - 0.7

Ni 0.3 max

S 0.025 max

P 0.03 max

Cr 1.5-1.8

Mo 0.6-0.8

V 0.15-0.3

Cu 0.2 max

FOllowing is mechanical property of 25Ch1M1F,21Kh1M1F,25Х1М1Ф forged steel turbine bolts

Rm - Tensile strength (MPa) (+QT)Tensile strength, Rm = 700 - 850 MPa

Yield point, Re > 550 MPa

Elongation, A > 16%

Reduction, Z > 60%

Notch toughness, KV20℃ > 63 J

Yield point at individual temperatures

Re At temperature at 200℃ min 500 MPa

Re At temperature 300℃ min 460 MPa

Re At temperature 400℃ min 412 MPa

Re At temperature 500℃ min 334 MPa

Re At temperature 550℃ min 275 MPa

All our Reports 25Х1М1ФA,25Ch1M1F,21Kh1M1F,25Х1М1Ф forging material shall be provided of all activities as indicated on the Inspection and Test Plan

These shall include:

1) Purchase order number and order item of 25Х1М1ФA material

2) Drawing number. of 25Ch1M1F forging parts

3) Clients definition specification number (ATD).25Х1М1Ф forging

4) Number of forgings in the batch. in 21Kh1M1F orging steel flat bars

5) Batch identity of the 25Х1М1ФA, forgings.

6) Statement of conformity with the Manufacturing, Inspection and Control Process Plan[MPP] and any agreed deviations.of 21Kh1M1F forging steel material

7) Statement of compliance with the forging deformation requirements. for 21Kh1M1F material

8) Details of heat treatments including time at soaking temperature, cooling methods and terminal temperature on cooling (where required by the material specification). of X8CrNiMoVNb16-13 forging pipes

9) Chemical analysis of all 25Х1М1Ф forging parts

10) Results of required mechanical tests. of 25Х1М1ФA forging rings

11) Results of hardness tests of all 25Ch1M1F forgings

12) Results of required microstructural tests (where applicable) of 21Kh1M1F forging steel

13) Certificate of conformity of dimensions for 25Х1М1ФA forged parts

Welcome your inquiry of 25Х1М1ФA,25Ch1M1F,21Kh1M1F,25Х1М1Ф forging forged steel parts