Description

Jiangsu Liangyi professional manufacturer of 1.4988,X8CrNiMoVNb16-13 ,X8CrNiMoVNb16.13,X8CrNiMoVNb1613 open die forging parts and seamless rolled rings factory from china

1.4988,X8CrNiMoVNb16-13 is Hardenable austenitic high temperature special steel with resistance to scaling up to 750 °C and high temperature strength up to 650 °C. Application: steam vessel and turbine manufacturing, in the chemicals industry and petrochemistry, for power plant pipes and in the hardened condition for blades, spindles, screws,bolts in the power plant engineering

Chemical composition of 1.4988,X8CrNiMoVNb16-13 forging steel is as follows

Limiting composition (melt analysis) in mass % shall be as defined in Table 1.

Element Symbol Range (mass %)

Carbon C 0.04 to 0.10

Silicon Si 0.30 to 0.60

Manganese Mn max. 1.50

Phosphorus P max. 0.035

Sulphur S max. 0.015

Nickel Ni 12.50 to 14.50

Chromium Cr 15.50 to 17.50

Molybdenum Mo 1.10 to 1.50

Vanadium V 0.60 to 0.85

Nitrogen N 0.060 to 0.140

Niobium Nb 10 x C% to 1.20

1.4988 forging steel shall be supplied in the precipitation hardened (+P) condition. in following process

Solution annealing heat treatment

Table 3: Solution annealing heat treatment cycle

Process Unit Range

Solutionising °C 1100 to 1150

Duration Hour min. 1.0

Cooling Air cooled or water quenched

3.1.2 Precipitation heat treatment

Table 4: Precipitation heat treatment cycle

Process Unit Range

Precipitation °C 750 to 880

Duration Hour min. 1.0

Cooling Air cooled

Mechanical properties of 1.4988,X8CrNiMoVNb16-13 forged steel parts is as following

Mechanical property requirements at 23°C ± 5°C shall be as defined in Table 2.

Table 2: Limiting mechanical properties in the precipitation hardened (+P) condition.

Property Unit Orientation Range

Tensile strength (Rm) MPa Long/Trans 540 to 740

Yield / 0.2% Proof strength:(Re/Rp0.2) MPa Long/Trans min. 255

Elongation on 5.65√So(A) %

Longitudinal min. 30

Transverse min. 20

Tangential min. 20

Notch impact strength (KV) J

Longitudinal min. 50

Transverse min. 35

Tangential min. 35

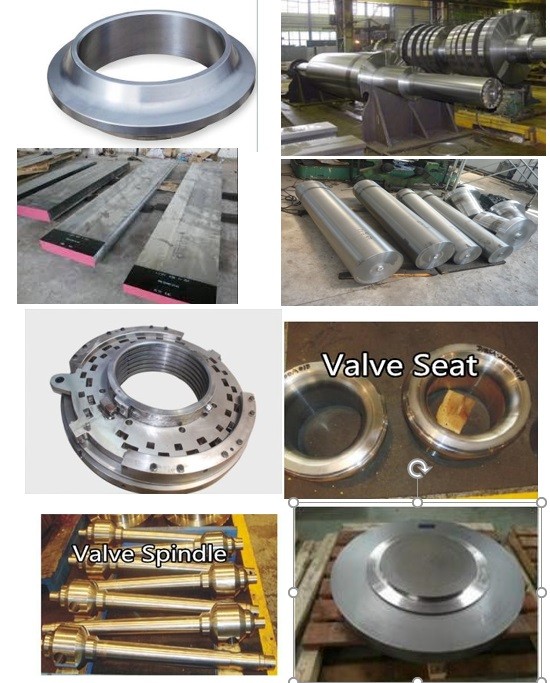

Following is the shape of 1.4988,X8CrNiMoVNb16-13 forging steel material that we could do is:1.4988 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X8CrNiMoVNb16-13 Forged forging steel rings seamless rolled rings, 1.4988 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.4988 Forged Forging Steel Discs Disks Blocks plates,X8CrNiMoVNb16.13 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.X8CrNiMoVNb16.13 Forged Forging Steel Gas Steam Turbine Rotors Shafts,X8CrNiMoVNb16-13F Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars,X8CrNiMoVNb1613 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,1.4988 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,X8CrNiMoVNb16-13 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

All our Reports 1.4988,X8CrNiMoVNb16-13 forging material shall be provided of all activities as indicated on the Inspection and Test Plan

These shall include:

1) Purchase order number and order item of 1.4988 material

2) Drawing number. of X8CrNiMoVNb16-13 forging parts

3) Clients definition specification number (ATD).X8CrNiMoVNb16-13 forging

4) Number of forgings in the batch. in X8CrNiMoVNb16-13 forging steel flat bars

5) Batch identity of the 1.4988 forgings.

6) Statement of conformity with the Manufacturing, Inspection and Control Process Plan[MPP] and any agreed deviations.of X8CrNiMoVNb16-13 forging steel material

7) Statement of compliance with the forging deformation requirements. for 1.4988 material

8) Details of heat treatments including time at soaking temperature, cooling methods and terminal temperature on cooling (where required by the material specification). of X8CrNiMoVNb16-13 forging pipes

9) Chemical analysis of all 1.4988 forging parts

10) Results of required mechanical tests. of 1.4988 forging rings

11) Results of hardness tests of all X8CrNiMoVNb16-13 forgings

12) Results of required microstructural tests (where applicable) of X8CrNiMoVNb16-13 forging steel

13) Certificate of conformity of dimensions for X8CrNiMoVNb16-13 forged parts

Welcome your inquiry of 1.4988,X8CrNiMoVNb16-13 forging forged steel parts