Description

Jiangsu Liangyi is professional manufacturer of AISI 304LN,UNS S30453,Grade 304LN,SUS 304LN,TP 304LN,AISI 304 LN open die forging parts and seamless rolled steel forged rings from china

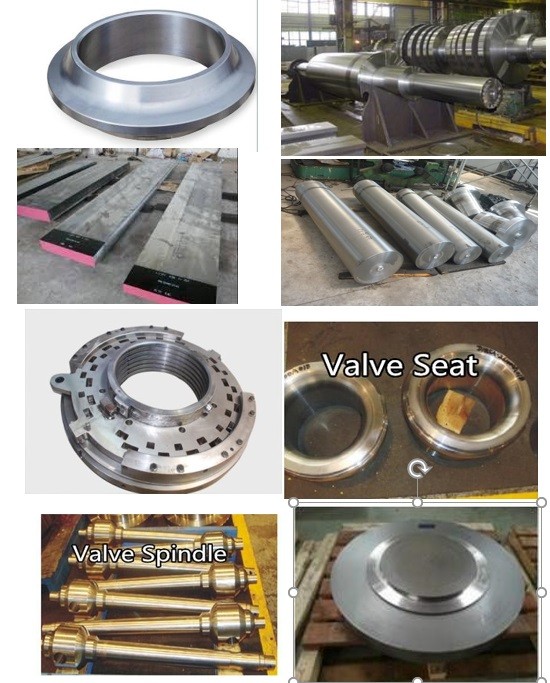

Following is the shape of AISI 304LN,UNS S30453,Grade 304LN,SUS 304LN,TP 304LN,AISI 304 LN forging steel material that we could do is: AISI 304LN Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AISI 304LN Forged forging steel rings seamless rolled rings,UNS S30453 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS S30453 Forged Forging Steel Discs Disks Blocks plates,AISI 304LN Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 304LN,UNS S30453,Grade 304LN,SUS 304LN,TP 304LN,AISI 304 LN material that is used in following industry

Grade 304LN Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

UNS S30453 Forged Forging Steel nuclear Power

Grade 304LN Forged Forging Steel Butterfly Valve Main Shafts Spindles

UNS S30453 Forged Forging Swept branches outlets steel fittings swept saddles

AISI 304LN Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AISI 304LN Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Grade 304LN Forged Forging venturi cone meter Body Bodies Blocks

UNS S30453 Forged Forging Steel gate valves Body Bodies bespoke flat bars

AISI 304LN forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Grade 304LN forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AISI 304LN Forged Forging Steel double studded adapter flange

AISI 304LN Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS S30453 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

AISI 304LN Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Grade 304LN Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Duplex Stainless Steel 2205 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

AISI 304LN Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

UNS S30453 Forged Forging forge Steel transition Cone

UNS S30453 Forged Forging Steel Pressure Vessel Reactor Nozzles

AISI 304LN forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AISI 304LN is a low-carbon, higher nickel and nitrogen alloyed alternative to Core 304/4301 with improved strength and low-temperature toughness. Suitable for applications that require high tensile strength. is an austenitic stainless steel that belongs to the standard CrNi stainless steel family.

The austenitic CrNi standard grades are the most widely used group of stainless steels. Their well-balanced material properties make them suitable for the fabrication of many products. Due to its fully austenitic structure, AISI 304LN is suitable for applications with low magnetic permeability requirements (µ < 1.005).

MELT PRACTICE of Grade 304LN forged parts

Steels made to this specificationshall be produced using refining and melt practices that can produce steels that are free from detrimental defects. The electric furnace methodshall be used to produce steels for this specification. Refining practices including argon / oxygen decarburization and vacuum degassing are acceptable.

FORGING PRACTICE

Forging practice shall be in accordance with ASTM A788.

REDUCTION RATIO

The minimum forging reduction ratio of UNS S30453 forging parts shall be 3 to 1.

FOllowing is chemical compostion of AISI 304LN,Grade 304LN forged steel rings

Carbon 0.03 max

Manganese 2.00max

Phosphorus 0.045 max

Sulfur 0.03 max

Silicon 2.00 max

Chromium 18.0-20.0

Nickel 8.0-12.0

Nitrogen 0.1-0.16

Following of AISI 304LN,Grade 304LN forging parts heat treatment nechanical property Delivery condition :

Tensile Strength ……………………. 515 (MPa)

Yield strength ……………………….. 205 (MPa)

Elongation …………………………… 40% max.

Material Qualification Test Coupons (QTC) of AISI 304LN forging parts :

. QTC shall be used to establish the mechanical properties of each forging or bar product.

. Minimum one QTC will be required for each heat / per heat-treat lot. A QTC shall be obtained from either of the following:

A prolongation shall betaken from the ¼ T envelope location of the thickest section. 2. A sacrificial forging that is cut into specified segments for test coupons.

ALl our finished forged AISI 304LN parts should be accepted by the QC department of the manufacturer by conducting the following

examinations:

1) external examination;

2) a check of dimensions and marking;

3) chemical composition examination;

4) mechanical tests;

5) macrostructure examination;

6) residual stress measurement;

7) ultrasonic testing;

8) periscopic testing.

Welcome your inquiry of AISI 304LN,UNS S30453,Grade 304LN,SUS 304LN,TP 304LN,AISI 304 LN forging forged steel parts