Description

Jiangsu Liangyi professional manufacturer of ASTM A565 Grade 616 Gr.616 A565 Gr616 Gr 616 A 565 GRD 616 AISI 616 , SUS 616 SUH616 SUH 616, Alloy 616 open die forging parts and seamless rolled steel forged rings,forging steel gas steam turbine blade steel flat bars from china

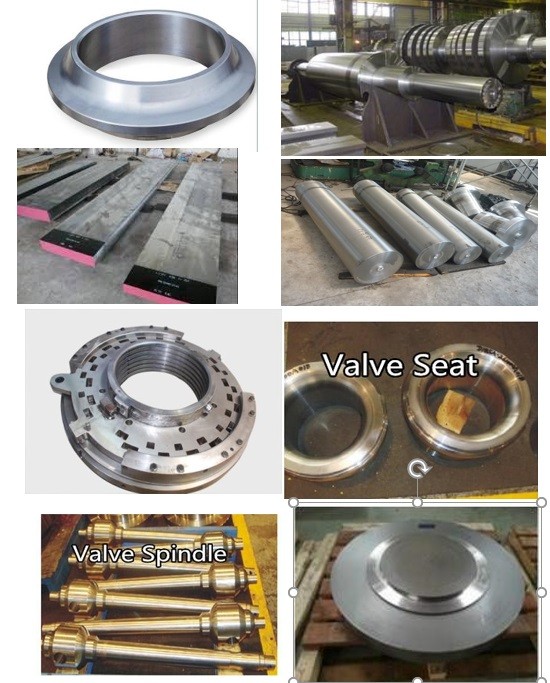

Following is the shape of ASTM A565 Grade 616 Gr.616 A565 Gr616 Gr 616 A 565 GRD 616 ,AISI 616 , SUS 616 SUH616 SUH 616, Alloy 616 forging steel material that we could do is:ASTM A565 Grade 616 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,A565 Gr616 Forged forging steel rings seamless rolled rings,SUS 616 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,SUS 616 Forged Forging Steel Discs Disks Blocks plates,AISI 616 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of ASTM A565 Grade 616 that is used in gas steam turbine

ASTM A565 Grade 616 Forged Forging Steel Gas Steam Turbine blade steel

A565 Gr616 Forged Forging Steel Gas Steam turbine rotor shafts

ASTM A565 Gr.616 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

A565 Gr616 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AISI 616 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings/Blade Fitting Rings

Alloy 616 Forging Forged Steel Gas Turbine Wheels Discs turbine impeller turbine blisks

AISI 616 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

A 565 GRD 616 Forged Forging Rolled Steel Gas Turbine LPT 1st & 2st 2nd Stg Stage Steam Turbine shrouds turbines journal and thrust bearing

Grade 616 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AIsi 616 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AISI 616 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

1.4935 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

ASTM A565 Gr.616 Forged Forging Steel Gas Steam Turbine Oil Guards nozzle Bearing Gland Seal Sealing Rings,

ASTM A565 Grade 616 forging Steam Gas Turbine Inlet Guide Vane IGV Control Ring Lower Upper Half,Outer Inner Transition Ducts,

AISI 616 forged Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields,

ASTM A565 Grade 616 (AISI 616,SUH 616) is is a hardenable martensitic type stainless steel recommended for high temperature applications up to 1200 F. It is used for steam turbine blades and buckets, valves, jet engine components, and high temperature bolting.

Our ASTM A565 Grade 616 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

Chemical composition % of steel ASTM A565 Grade 616 (AISI 616,SUH 616) forged steel round bars:

C (%): 0.20 ~ 0.25

Si (%): ≤ 0.50

Mn (%): 0.50 ~ 1.00

P (%)≤: 0.025

S (%)≤: 0.015

Cr (%): 11.0 ~ 12.5

Ni (%): 0.50 ~ 1.00

Mo (%): 0.90 ~ 1.25

W (%): 0.90 ~ 1.25

V (%): 0.20 ~ 0.30

Mechanical properties of steel ASTM A565 Grade 616 (AISI 616,SUH 616) forging steel gas turbine blade flat bars

Creep limit for of ASTM A565 Grade 616 (AISI 616,SUH 616) forging steel turbine blade steel

high temperature test:Testing temperature: 400 °C - > 420 MPa

Testing temperature: 500 °C - > 335 MPa

Mechanical properties of +QT700 class forgings:Ambient temperature:

Re: > 500 MPa Rm: 700-850 MPa

A: 15 %

Yield strength Re in high temperature for ASTM A565 Grade 616 (AISI 616,SUH 616) forging steel round bars

Testing temperature: 50 °C - > 465 MPa

Testing temperature: 100 °C - > 460 MPa

Testing temperature: 150 °C - > 445 MPa Testing temperature: 200 °C - > 430 MPa

Testing temperature: 250 °C - > 415 MPa Testing temperature: 300 °C - > 390 MPa

Testing temperature: 350 °C - > 380 MPa Testing temperature: 400 °C - > 360 MPa

Testing temperature: 450 °C - > 330 MPa Testing temperature: 500 °C - > 290 MPa

Testing temperature: 550 °C - > 250 MPa

Mechanical properties of +QT800 class of ASTM A565 Grade 616 (AISI 616,SUH 616) forging parts

Re: > 600 MPa

Rm: 800-950 MPa

A: 14 %

Yield strength Re in high temperature:

Testing temperature: 50 °C - > 585 MPa

Testing temperature: 100 °C - > 560 MPa

Testing temperature: 150 °C - > 545 MPa

Testing temperature: 200 °C - > 530 MPa

Testing temperature: 250 °C - > 505 MPa

Testing temperature: 300 °C - > 480 MPa

Testing temperature: 350 °C - > 450 MPa T

esting temperature: 400 °C - > 420 MPa

Testing temperature: 450 °C - > 380 MPa

Testing temperature: 500 °C - > 335 MPa

Testing temperature: 550 °C - > 280 MPa

FOllowing is ASTM A565 Grade 616 (AISI 616,SUH 616) forged steel all testing that we will do

MATERIAL TESTS of ASTM A565 Grade 616 forging turbine blade steel

CHEMIST test of AISI 616 forging parts

MATERIAL FOR TESTS REMOVE FROM ADDENDUM FOR TESTS

3X TENSION TEST ACC. T0 EN ISO 6892- -1 of SUH 616 forging material

3X NOTCH TOUGNESS TEST ACC. T0 IS0 148-1 of grade 616 forged rings

UL TRASONIC DETECTION WLL BE MAKED ON THE MACHINED FORGING ACC.T0 CSN EN 10228- -3, QUALITY CLASS 3 for all grade 616 forgings

RANGE 0F ULTRASONIC TESTS:

- BY A DIRECTLY PROBE IN THE RANGE OF 100%(360") FROM THE ROLLED SURFACEAND FROM THE FRONT SURFACES

- BY AN ANGLE PROBE FOR LONGITUDINAL AND TRANSVERSE DEFECTS

IN THE RANGE OF 100%(360") FROM THE ROLLED SURFACE

BY A DOUBLE-PROBE IN THE AREA UNDER THE TEST SURFACE WHERE IT IS NOT POSSIBLT0 CARRY OUT EVALUATION 0F DEFECTS BY THE DIRECT PROBE TEST

REGISTRATION LEVEL:

FOR THE DIRECT AND DOUBLE-PROBES ACCORDING T0 TB...SRR = 3mm

DECREASE OF END ECHO.... = 0.5

- FOR THE DOUBLE-PROBES ACCORDING T0 TAB.... = 3mm

- FOR ANGLE PROBES ACCORDING TO T......... = 3mm