Description

Jiangsu Liangyi professional manufacturer of 26NiCrMoV11-5,1.6948,26NiCrMoV115,26NiCrMoV11.5,26 NiCrMoV 11 5 open die forging parts and forged steel gas steam turbine generator rotor shafts ,26NiCrMoV115 forged steel Gas steam turbine high pressure and intermediate pressure rotors, monobloc rotors, shaft ends, hollow shafts factory from china

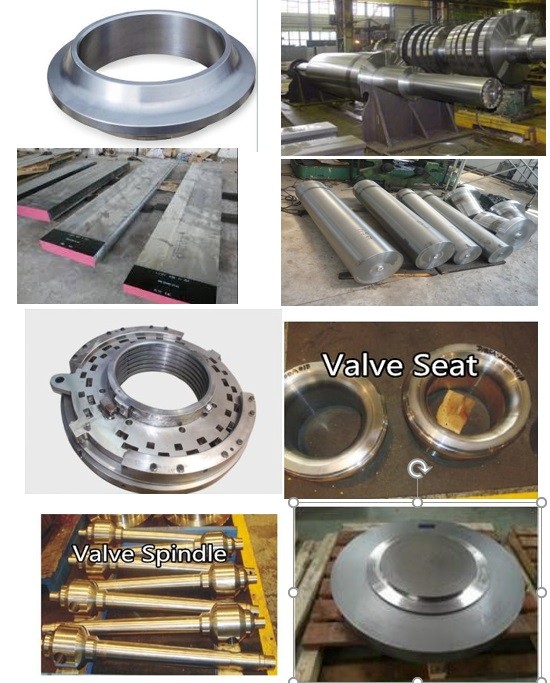

Following is the shape of 26NiCrMoV11-5,1.6948,26NiCrMoV115,26NiCrMoV11.5,26 NiCrMoV 11 5 Forging steel material that we could do is:26NiCrMoV11-5 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, 26NiCrMoV115 Forged forging steel rings seamless rolled rings, 26 NiCrMoV 11 5 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,26NiCrMoV11.5 Forged Forging Steel Discs Disks Blocks plates, 1.6948 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.26NiCrMoV11-5 Forged Forging Steel Gas Steam Turbine Rotors Shafts,26 NiCrMoV 11 5 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars,26NiCrMoV11-5 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,26NiCrMoV11.5 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,1.6948 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

The capacity of our 1.6948 forged turbine rotor shafts that we could produce is as following, the maximum weight of 26NiCrMoV115 forged turbine shafts that we could produce is 30 tons, the maximum length of 26NiCrMoV11.5 forged turbine rotor shafts that we could produce is up to 15 meter, the maximum diameter of 26NiCrMoV11.5 forged turbine shafts that we could produce is up to 2 meter

Our 26NiCrMoV11-5 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

CHEMICAL COMPOSITION (WEIGHT %) of 26NiCrMoV11-5 forged gas turbine rotor shafts is as followings

C (%): 0.22 ~ 0.32

Si (%): ≤ 0.15

Mn (%): 0.15 ~ 0.40

P (%)≤: 0.015

S (%)≤: 0.010

Cr (%): 1.20 ~ 1.80

Mo (%): 0.25 ~ 0.45

Ni (%): 2.40 ~ 3.10

V (%): 0.05 ~ 0.15

MECHANICAL PROPERTIES - AFTER HEAT TREATMENT FOR 26NiCrMoV11.5 FORGED steam turbine rotor shafts is as following

Tensile strength, ≥/MPa: 850

Yield strength, ≥/MPa: 750

Elongation, ≥/(%): 18.0

Reduction of area, ≥/(%): 42.0

All our forged 26NiCrMoV115 forged gas turbine rotor shafts can be release en10204-3.1 certificate, or en10204-3.2 inspection certificate from following third party,3.2 mit TUV ,GL (Germanischer Lloyd),BV (Bureau Veritas),DNV (Det Norske Veritas),ABS (American Bureau of Shipping),Lloyds Register of Shipping, RMRS (Russian Maritime Register of Shipping),RINA (Registro Italiano Navale)

Welcome your inquiry of 26NiCrMoV11-5,1.6948,26NiCrMoV115,26NiCrMoV11.5,26 NiCrMoV 11 5 forging forged steel parts