Description

Jiangsu Liangyi is professional manufacturer of AISI 317L,UNS S31703,Grade 317L,SUS 317 L,TP 317L,AISI 317 L open die forging parts and seamless rolled steel forged rings from china

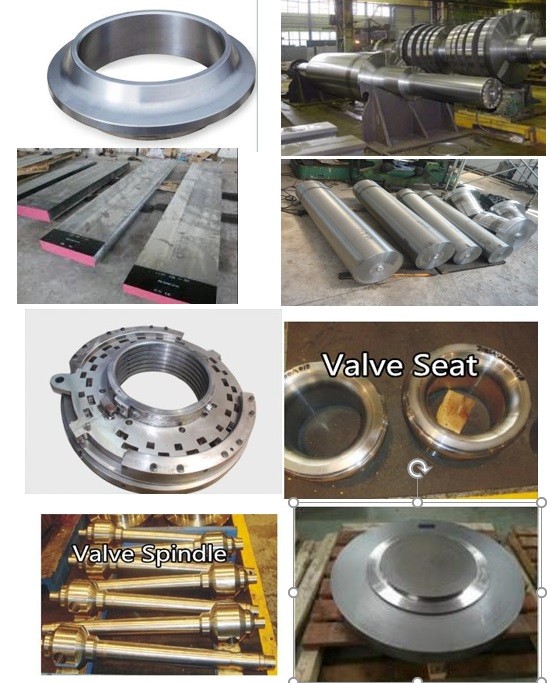

Following is the shape of AISI 317L,UNS S31703,Grade 317L,SUS 317L,TP 317 L,AISI 317 L forging steel material that we could do is: AISI 317L Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AISI 317L Forged forging steel rings seamless rolled rings,UNS S31703 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS S31703 Forged Forging Steel Discs Disks Blocks plates,AISI 317L Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 317L,UNS S31703,Grade 317L,SUS 317 L,TP 317L,AISI 317 L material that is used in following industry

Grade 317L Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

UNS S31703 Forged Forging Steel nuclear Power

Grade 317L Forged Forging Steel Butterfly Valve Main Shafts Spindles

UNS S31703 Forged Forging Swept branches outlets steel fittings swept saddles

AISI 317L Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AISI 317L Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Grade 317L Forged Forging venturi cone meter Body Bodies Blocks

UNS S31703 Forged Forging Steel gate valves Body Bodies bespoke flat bars

AISI 317L forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Grade 317L forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AISI 317L Forged Forging Steel double studded adapter flange

AISI 317L Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS S31703 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

AISI 317L Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Grade 317L Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Duplex Stainless Steel 2205 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

AISI 317L Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

UNS S31703 Forged Forging forge Steel transition Cone

UNS S31703 Forged Forging Steel Pressure Vessel Reactor Nozzles

AISI 317L forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AISI 317L is s a lowcarbon corrosion resistant austenitic chromium-nickel-molybdenum stainless steel. The high levels of these elements assure the alloy has

superior chloride pitting and generalcorrosion resistance to the conventional 304/304L and 316/316L grades. The alloy provides improved resistance relative to 316L in strongly corrosive environments containing sulfurous media, chlorides, and other halides.

FOllowing is chemical compostion of AISI 317L,Grade 317L forged steel rings

Iron, Fe Balance

Chromium, Cr 18-20

Nickel, Ni 11-15

Molybdenum, Mo 3-4

Manganese, Mn 2

Silicon, Si 1

Phosphorous, P 0.045

Carbon, C 0.03

Sulfur, S 0.03

Following of AISI 317L,Grade 317L forging parts heat treatment nechanical property Delivery condition :

Tensile strength 595 MPa 86300 psi

Yield strength 260 MPa 37700 psi

Elongation at break (in 50 mm) 55% 55%

Hardness, Rockwell B 85 85

For melting AISI 317L,Grade 317L forging steel material, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

In order to make forging and make heat treatment AISI 317L,Grade 317L forging steel parts, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m

All our AISI 317L,UNS S31703 forged pipes will have following inspection:

Chemical analyses

Mechanical analyse

UT testing according several norms

MPI testing

Spectral analyse

Hardness measurement according several methods

Tensile and bending tests

Impact test according several methods

Microscope investigation

Huey test

Interkristal corrosion test

Red white test

X-Ray test

3D dimensional check

Magnetic test

Dye penetrant test

Positive Alloy Material Identification (PAMI)

Magnetic particle test

Welcome your inquiry of AISI 317L,UNS S31703,Grade 317L,SUS 317L,TP 317L,AISI 317 L forging forged steel parts

Following is the shape of AISI 317L,UNS S31703,Grade 317L,SUS 317L,TP 317 L,AISI 317 L forging steel material that we could do is: AISI 317L Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AISI 317L Forged forging steel rings seamless rolled rings,UNS S31703 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS S31703 Forged Forging Steel Discs Disks Blocks plates,AISI 317L Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 317L,UNS S31703,Grade 317L,SUS 317 L,TP 317L,AISI 317 L material that is used in following industry

Grade 317L Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

UNS S31703 Forged Forging Steel nuclear Power

Grade 317L Forged Forging Steel Butterfly Valve Main Shafts Spindles

UNS S31703 Forged Forging Swept branches outlets steel fittings swept saddles

AISI 317L Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AISI 317L Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Grade 317L Forged Forging venturi cone meter Body Bodies Blocks

UNS S31703 Forged Forging Steel gate valves Body Bodies bespoke flat bars

AISI 317L forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Grade 317L forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AISI 317L Forged Forging Steel double studded adapter flange

AISI 317L Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS S31703 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

AISI 317L Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Grade 317L Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Duplex Stainless Steel 2205 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

AISI 317L Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

UNS S31703 Forged Forging forge Steel transition Cone

UNS S31703 Forged Forging Steel Pressure Vessel Reactor Nozzles

AISI 317L forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AISI 317L is s a lowcarbon corrosion resistant austenitic chromium-nickel-molybdenum stainless steel. The high levels of these elements assure the alloy has

superior chloride pitting and generalcorrosion resistance to the conventional 304/304L and 316/316L grades. The alloy provides improved resistance relative to 316L in strongly corrosive environments containing sulfurous media, chlorides, and other halides.

FOllowing is chemical compostion of AISI 317L,Grade 317L forged steel rings

Iron, Fe Balance

Chromium, Cr 18-20

Nickel, Ni 11-15

Molybdenum, Mo 3-4

Manganese, Mn 2

Silicon, Si 1

Phosphorous, P 0.045

Carbon, C 0.03

Sulfur, S 0.03

Following of AISI 317L,Grade 317L forging parts heat treatment nechanical property Delivery condition :

Tensile strength 595 MPa 86300 psi

Yield strength 260 MPa 37700 psi

Elongation at break (in 50 mm) 55% 55%

Hardness, Rockwell B 85 85

For melting AISI 317L,Grade 317L forging steel material, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

In order to make forging and make heat treatment AISI 317L,Grade 317L forging steel parts, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m

All our AISI 317L,UNS S31703 forged pipes will have following inspection:

Chemical analyses

Mechanical analyse

UT testing according several norms

MPI testing

Spectral analyse

Hardness measurement according several methods

Tensile and bending tests

Impact test according several methods

Microscope investigation

Huey test

Interkristal corrosion test

Red white test

X-Ray test

3D dimensional check

Magnetic test

Dye penetrant test

Positive Alloy Material Identification (PAMI)

Magnetic particle test

Welcome your inquiry of AISI 317L,UNS S31703,Grade 317L,SUS 317L,TP 317L,AISI 317 L forging forged steel parts