Description

Jiangsu Liangyi professional manufacturer of AISI 403CB,AISI 403 CB,AISI 403, UNS S40300 open die forging parts and seamless rolled steel forged rings,410CB forged forging steel gas steam turbine blade bolts from china

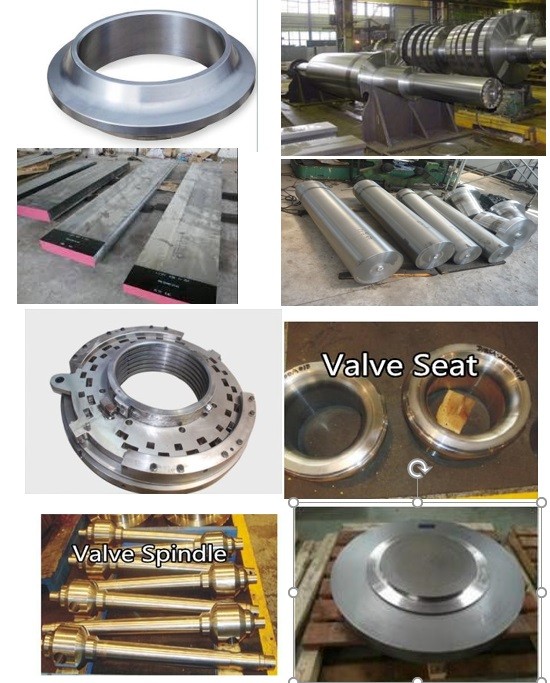

Following is the shape of AISI 403CB,AISI 403 CB,AISI 403, UNS S40300 forging steel material that we could do is:403CB Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AISI 403 Forged forging steel rings seamless rolled rings,AISI 403CB Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AISI 403 CB Forged Forging Steel Discs Disks Blocks plates,UNS S40300 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 403CB that is used in following industry

AISI 403CB Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

403 CB Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AISI403CB Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

AISI 403 CB Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AISI 403CB forged forging steel pump case, pump impeller, pump wear rings, pump shafts

AISI 403CB forged forging steel valve bonnet, valve body, valve closure, valve stems, valve seat rings, valve core, valve discs

403CB is Chromium –Niobium martensitic stainless steel designed to supply a good corrosion resistance in mild environments, high mechanical and creep resisting properties together with high toughness.

Due to a special chemical composition and exact steel making process, 410CB forged steel parts is widely used in the power generation industries and in steam turbine blade production. And in other applications where high temperature resistance is required, such as turbine discs, bolting, fasteners, screws, pins and rings, parts of petrochemical plants, gas turbine compressor components, pump parts and valve components.

FOllowing is chemical compostion of AISI 403 forged steel flat bars

C (%): 0.13 ~ 0.18

Si (%): ≤ 0.50

Mn (%): 0.40 ~ 0.60

P (%)≤: 0.025

S (%)≤: 0.010

Cr (%): 11.5 ~ 13.0

Ni (%): ≤ 0.60

Nb (%): 0.15 ~ 0.45

FOllowing is mechanical property for 403CB forging steel parts

Tensile strength, TS, σb/≥ MPa: 828 according to standard of EN 10002-1

Yield strength, YS, σ0.2/≥ MPa: 725 according to standard of EN 10002-1

Elongation, EL, δ ≥(%): 17.0 according to standard of EN 10002-1

Recution of area, RA, ф ≥ (%): 50.0 according to standard of EN 10002-1

Hardness | HB: 255 ~ 302 according to standard of IS0 6506-1

An inspection certificate 3.1 for UNS S40300 forged parts according to Standard EN 10204 and relative ITP in English language shall be provided in duplicate to the clientsprior to, but in no case later than with the delivery of the 403CB forged material and shall contain the following data:

a) Identification no. And order no. of 403CB forging parts

b) Material designation of 403 CB forged rings

c) Heat No. and heat analysis including trace elements and melting process.of each AISI 403CB forging sleeves

d) Number of forgings in the ingot and weight of ingot, stating L/D ratio.

e) Degree of forging reduction (Amax/Afinal at greatest body diameter) of each AISI 403 forging round bars

f) Heat treatment: Method of cooling, temperatures actually measured, holding times and cooling conditions (cooling rates) of each AISI 403CB forged turbine blade steel

including all reheat treatments are to be quoted as a complete temperature time sequence.

g) Results of the mechanical test. All results shall be quoted with indication of location of specimens of each 403cb forged steel bars

h) Results of residual stress measurement if performed.

i) Results of ultrasonic examination according to clients requirement

k) Results of magnetic particle inspection of axial and if applicable radial bores and the cross section transitions according to clients requirement

l) Results of magnetic properties of each AISI 403 CB forging steel flat bars

m) Dimensional data sheet about the dimensional inspection of each 403CB forging material