Description

Jiangsu Liangyi professional manufacturer of X17CrMoVNbB9-1,X17CrMoVNbB9.1,X17CrMoVNbB91 open die forging parts and forged steel gas steam turbine blade blading vane steel factory from china

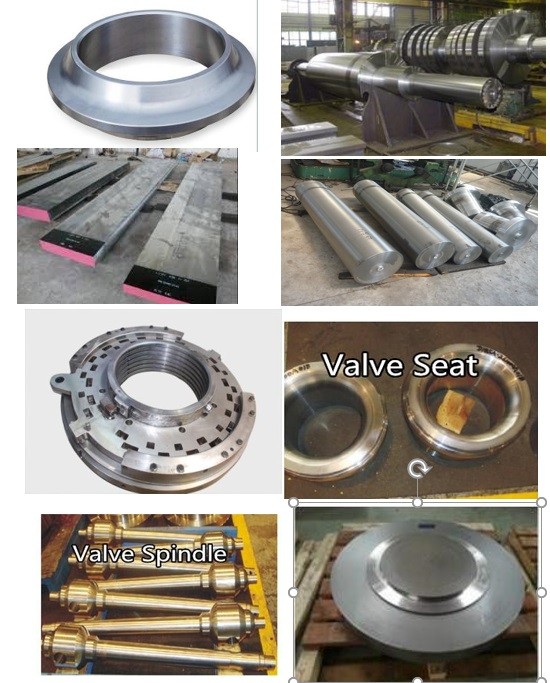

Following is the shape of X17CrMoVNbB9-1,X17CrMoVNbB9.1,X17CrMoVNbB91 Forging steel material that we could do is:X17CrMoVNbB9-1 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, X17CrMoVNbB91 Forged forging steel rings seamless rolled rings, X17CrMoVNbB9.1 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X17CrMoVNbB9-1 Forged Forging Steel Discs Disks Blocks plates, X17CrMoVNbB91 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings. X17CrMoVNbB9-1 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars, X17CrMoVNbB91 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,

MATERIAL SPECIFICATIONS of X17CrMoVNbB9-1 forging gas turbine blading steel

CHEMICAL COMPOSITION (WEIGHT %)

C (%): 0.12-0.19

Si (%): ≤ 0.10

Mn (%): ≤ 0.15

P (%)≤: 0.020

S (%)≤: 0.010

Cr (%): 8.50 -9.50

Ni (%): ≤ 0.30

Mo (%): 1.40 - 1.70

V (%): 0.24 - 0.30

Nb (%): 0.04 - 0.07

B (%): 0.007 - 0.010

Other (%): Cu ≤ 0.15

N ≤ 0.020

mechnical property of X17CrMoVNbB9-1 forging steam turbine blade flat bars material

Tensile strength, σb ≥/MPa: 850 -1000

Yield strength, σ0.2 ≥/MPa: 700

Elontation, δ ≥(%): 12.0

Reduction of area, ф ≥(%): 40.0

Hardness | HBW: 255 -302

Our X17CrMoVNbB9-1 Forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS to improve high perity of blade steel material

The purity grade of the X17CrMoVNbB9-1 forged gas turbine blading material is to be determined per DIN 50602-K1.The following value is to be kept in this case(on 1000 mm²)-Sum characteristics value K1:≤2.0

For determination 4 tests per heat are to be employed at least Depending on the appearance of the analysed microsections also higher K1-Values may possibly be Tolerated.Content of Delta-Ferrite Delta ferrite content:<5% (Determined in a manner consistent with the evaluation technique described in ASTM E 45/Method A,"Worst Field Method"at V=100,specimen orientation:longitudinal.Thedistribution and size of delta ferrite must be such that it does not result in indication in magnetic particle testing of the ready-machined surface.)

All finished X17CrMoVNbB9-1 forging turbine blade flat bars are to be marked with supplier's symbol,material designation,melt number,and identification number qiven on the order.The details are to be clearly stamped and

encircled by oil paint.Each X17CrMoVNbB9-1 forged turbine bar shall be painted with orange-orange-blue colour at one end.All the bars shall be suitably packed to protect them against corrosion and damage during transportation.Bars having maximum and minimum hardness (from which test samples are taken)shal be clearly marked by oil paint for easy identification.Their respective hardness values shall also be punched on these bars

ALl our finished producrtion of X17CrMoVNbB9-1 forged turbine blade flat bars should have inspection certificate as per 3.1B of EN 10204 shall be provided to clients in triplicate;this certificate must contain the following dala:

(a)Material code no and P.O.number

(b)Material designation

(c)Heat no.,heat analysis and melting methods

(d)Table with the single results for determination pf the purity grade at microsections and value of purity grade K1

(e)Mechanical test results including hardness range

(f)Complete information on all heat treatments performed

(g)Results of NDT tests performed

(h)Confimation of material identification check

(i)Confirmation of dimensional and visual check

Following is testing standard of X17CrMoVNbB9-1 forged turbine blade steel

EN ISO 9000FF,EN 10002-1,ASTM E8M,ASTM E8,EN10045,EN10021,EN ISO 6506-1,ASTM E112,DIN 50602,DIN50601,ASTM E45,SEP 1923,EN 10204,ASTM A370,MUN 106.2/1.

aLL X17CrMoVNbB9-1 FORGED Turbine blade Specimens in transverse direction for information.If it is not possible to take standard specimen in transverse direction,the following specimen shall be used:

For tensile testing,a round tensile test specimen of Lo=5 do or sheet type specimen with a coefficient of proportionality of k =5.65 shall be used.If ASTM E8 is applied,small size specimens may be used.

For impact testing,a subsidiary test piece according to EN 10045 shall be used

Any size or geometry deviating from the standard specimen must be indicated in MIP

magnetic flux leakage technique,phase shifted alternating curent,field strength 20 -65 A/cm.