Description

Jiangsu Liangyi is professional manufacturer of AISI 4320, SAE 4320H,UNS G43200,AISI 4320H open die forging parts and seamless rolled steel forged rings from china

Following is the shape of AISI 4320, SAE 4320H,UNS G43200,AISI 4320H forging steel material that we could do is:AISI 4320 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,

AISI 4320 Forged forging steel rings seamless rolled rings,SAE 4320H Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AISI 4320 forging forged steel shafts,gear,pinion shafts,spindles,gear wheel,SAE 4320H Forged Forging Steel Discs Disks Blocks plates,AISI 4320 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 4320, SAE 4320H,UNS G43200,AISI 4320H material that is used in following industry

AISI 4320 Forged Forging Sugar Mill Gear shafts,pinion shafts,roller shafts,flanges coupling

AISI 4320 Cement Mill Rotary Kiln Forged Forging Steel case hardened ground Pinion Shafts

SAE 4320H Forging Forging Steel mill gear pinion shafts

AISI 4320 Forging wind turbine gearbox gear shafts,ring gears

SAE 4320H forging forged locomotive transmission shafts

AISI 4320 forging forged crane wheels

AISI 4320 hydro turbine shafts

AISI 4320 Forging gearbox,gear reducer gear wheels, pinion shafts,ring gears,

AISI 4320 Forging crankshafts for gas compressor, mechanical presses,pump.

AISI 4320 forging steel Spindles

UNS G43200 Forging steel gear couplings

AISI 4320 Forged Forging Rolled Steel Granulators driers coaters coolers Riding Gear Rings

AISI 4320 Forged Forging Steel Cement Plant Pull Torque Rods

AISI 4320 Forged Forging Steel Crusher Shaft eccentric shafts,Mining Mine rock Gyratory crusher Eccentric shafts Spindles,Crusher Belt Pulley Wheels.

UNS G43200 Forged Forging Steel Mining Excavator Slewing Bearing Ball Races rings

AISI 4320 Forged Forging Steel Oil Drilling Tools Gear Shaft Pinion Shafts

AISI 4320 Forged Forging Steel helical gearing ground ship gearwheel Gear Wheels

AISI 4320 Forged Forging Steel Dragline Drag Line Power Shovel Cam Swing Shafts Shafting Spindles,dragline CENTRE PINTLE

AISI 4320 Forged Forging Steel Atomizer Shafts For Flue Gas Desulfurization scrubber Systems

AISI 4320 Forged Forging Steel drilling rigs Mud pump herringbone gear shafts pinion shafts

AISI 4320 Forging Forged Steel Thread Tie Rods

AISI 4320 Forged Forging Steel Electric Shovel Shaft Couplings

AISI 4320 Forged Forging Steel Granulator Gear Shafts

AISI 4320 Conveyor Pulley Forging Forged Steel Shafts factory

AISI 4320 Forged Forging Steel Hydraulic Honed Cylinders

UNS G43200 Forged Forging Steel Mine hoist systems Equipment Shaft Shafting Spindles

AISI 4320 Forged Forging Steel Rotary Dryer Trunnion Wheels

AISI 4320 Forged Forging Forge Steel Cold Mill Decoiler Coiler Mandrel Drum Shafts

AISI 4320 Forged Forging Steel bullgear Spider Gear Rims

UNS G43200 Forged Forging Shovel SWING Rimmed GEARING Gear DRUM GEAR,SWING PROPEL Pinion SHAFTS

AISI 4320 Forged Forging Steel Truck RING GEARS PLANET GEARS PINION SHAFTS

AISI 4320 Forging Forge Steel Offshore subsea anchor winches Stub Shafts Spindles

UNS G43200 Forged Forging Steel Seamless Hot rolled Truck concrete mixers semi-trailer bearings Rings

AISI 4320 Forged Forging Steel Subsea oil gas drilling equipments Box Riser Joint

AISI 4320 Forged Forging Railway locomotive Traction Motors end housings Rear End Shields

AISI 4320 Forged Forging Steel Gas Steam Turbine Labyrinth seal bushing

AISI 4320 Forged Forging Steel Gas Steam turbine generator air gap annular split baffle rings

AISI 4320 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies

AISI 4320 Forged Forging forge Steel Gas Steam turbine Power generator Shafts

AISI 4320 Forged Forging Gas Steam turbine Rotors Forward Stub Shafts Spindles

STEEL MAKING of AISI 4320 forging parts

Basic open hearth, basic oxygen or electric furnace steel

Chemical composition of UNS G43200 forged parts

| ELEMENT | 4320 | 4320H | |||||||||||||||||||||||||||||||||

|

Carbon Manganese Phosphorus Sulfur Silicon Nickel Chromium Molybdenum Iron |

0.17 - 0.22 0.45 - 0.65 0.035 Max 0.040 Max 0.15 - 0.35 1.65 - 2.00 0.40 - 0.60 0.20 - 0.30 Balance |

0.17 - 0.23 0.40 - 0.70 0.035 Max 0.040 Max 0.15 - 0.35 1.55 - 2.00 0.35 - 0.65 0.20 - 0.30 Balance |

|||||||||||||||||||||||||||||||||

GRAIN SIZE AND HARDENABILITY of SAE 4320 forged parts

All material furnished shall be fine grain, ASTM No. 5 or finer.

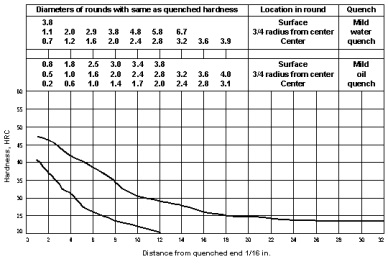

Hardenability limits for 4320H shall be governed by the methods of specification and the hardenability band shown below per latest issue of the appropriate AISI or SAE publication.

The above chart indicates the hardness values to be expected at three locations on a round specimen depending on section size cooling rate."

EXAMPLE

For a mild oil quench at a Jominy distance of 4/16"", a hardness range of Rc 32-43 could be expected at the surface of a 1.8"" diameter round or at the 3/4 radius location of a 1.0"" diameter round or at the center of a

0.6"" diameter round."

The chart below tabulates hardness values at various depths for certain size rounds. Data is based on End- Quench Hardenability test coupons made from wrought steel stock using a mildly agitated oil quench."

SIZE OF

ROUND

(INCHES)

HARDNESS (BHN)

SURFACE

3/4 RADIUS

1/2 RADIUS

CENTER

1” O.D.

393

352

322

297

2” O.D.

342

276

260

255

3” O.D.

270

250

240

235

4” O.D.

245

240

230

220

The above hardness values are approximate and should be used for design guidance only. Factors such as chemistry variation,

heat treating parameters, surface condition, grain size, component configuration (cooling

rate), and degree of tempering will affect final hardness."

Note that maximum surface hardness upon straight quenching (not considering surface treatment such as carburizing) this alloy is Rc 41-48

depending on chemistry variation and section size."

MECHANICAL PROPERTIES of AISI 4320 forged bars

"Mechanical properties in the annealed, normalized, and three fully quenched and tempered conditions are tabulated below.

It must be noted that these values are based on standard test coupons and that actual values

vary depending on section size. Desired hardness range and corresponding heat treatment are to be specified on the engineering drawing.

If specific areas of the component require different hardness ranges, that should

also be shown explicitly on the drawing."

Mechanical

Properties

![]()

![]()

![]() 197 Max *

197 Max *

![]()

![]() 241 Max **

241 Max **

![]()

![]()

![]()

Tensile Str. Min Psi

80,000

100,000

130,000

150,000

165,000

Yield Str. Min Psi

60,000

55,000

95,000

115,000

130,000

Elongation, Min %

25

20

18

15

12

Red. in Area, Min %

55

55

50

45

40

Impact Strength, ft-lb, Ref

Charpy V-Notch @ - 40oF

60

50

35

30

25

*Annealed Condition **Normalized Condition

Table 3: Mechanical Properties

This alloy is commercially known as a ""carburizing grade"". When carburizing or carbo-nitriding is desired, effective case depth and resultant surface hardness range are to be clearly specified on the engineering drawing. As quenched, Rc 63- 65 hardness is achieved but should be tempered to the desired hardness range (e.g., Rc 60-63, Rc 58-62, Rc 55-60).Core hardnesses and other properties will vary depending on degree of tempering."

Times and temperatures of heat treatment must be consistent with standard heat treating practices to obtain proper microstructure, case depths (when applicable), enhance grain refinement and avoid decarburization or over carburization." Cooling from the tempering temperatures must be rapid enough to avoid temper embrittlement in the 450oF - 800oF range. (A loss in toughness or impact strength occurs when heating or cooling slowly through this range.)"

Hardness tests should be taken on surfaces from which all foreign matter such as scale and decarburized metal have been removed."

QUALITY / MANUFACTURING PRACTICES of AISI 4320 forged parts

"Material furnished shall be commercially sound and free from external and internal defects that would make it unsuitable for forging, machining or heat treating normally employed in processing. This includes seams,

laminations, cold shuts, incipient melting (""burning""), and excessive non-metallic inclusions. Surfaces shall be free of high temperature scale."

Remnant as-case dendritic pattern or alloy segregation is undesirable in hot rolled or forged products. This should not be found in critical stress areas due to reduced mechanical properties and can pose machinability

problems. Areas considered as critical may be indicated on the engineering drawing."

All material furnished must be fully killed. The material may be subsequently processed by vacuum degassing, argon stirring, vacuum arc or electroslag remelting, controlled cooling, etc.

Except as noted above or unless otherwise specified on the purchase order, all material furnished shall be in accordance with the AISI and ASTM standard practices.

In cases not covered by specific standard practices, the product furnished shall be in accordance with accepted trade practices.

PACKAGING AND LOADING of finished AISI 4320 forged parts

All material should be bundled and loaded in accordance with the recommended standard practices defined in the contract with Purchaser.

All shipping notices shall include the Customer's Purchase Order Number.

IDENTIFICATION of finished SAE 4320 forged bars

Material shall be tagged as per standard practices of AISI and ASTM. All tags must show the following information:

Customer's Name and Purchase Order Number

Supplier's Name

Grade and Specification -

Size and Length of forged Plates, Bars, Rounds, Tubing and Pipe

Weight of Lift

Heat Number and original producing mill name

CLients Color Code - Gray and White - to be painted on one end of each piece.

Clients Color Code - Brown and Yellow and Black - to be painted on one end of each piece.

All AISI 4320 forged bars three inches in diameter or equivalent cross section or larger, all hot forged and rough machined rounds, and all semi-finished product shall be die stamped with the heat number on one end only."

AISI 4320 Forged special shapes must have the forging heat code forged or stamped in a location that will not be obliterated by machining or other means. It is advisable for the location of this code to be shown on the

engineering drawing."

Welcome your inquiry of AISI 4320, SAE 4320H,UNS G43200,AISI 4320H forged parts