Description

Jiangsu Liangyi is professional manufacturer of 1.7336,13CrMoSi5-5,13CrMoSi55,13CrMoSi5.5 open die forging parts

and seamless rolled steel forged rings from china

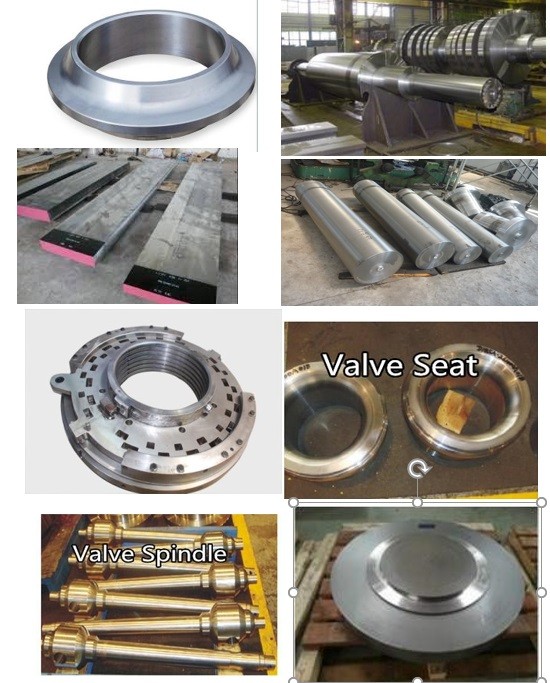

Following is the shape of 1.7336,13CrMoSi5-5,13CrMoSi55,13CrMoSi5.5 forging steel material that we could do is:

1.7336 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,13CrMoSi5-5 Forged forging steel rings seamless rolled rings,

13CrMoSi5.5 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.7336 Forged Forging Steel Discs Disks Blocks plates,

13CrMoSi55 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.7336,13CrMoSi5-5,13CrMoSi55,13CrMoSi5.5 material that is used in following industry

1.7336 Forged Forging Swivel Ring Flanges

13CrMoSi5-5 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

13CrMoSi5-5 Forged Forging Swept branches outlets steel fittings swept saddles

13CrMoSi5-5 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

13CrMoSi55 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

13CrMoSi55 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

1.7336 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

13CrMoSi5.5 Forged Forging forge Steel transition Cone

1.7336 Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

FOllowing is production standard of 1.7336 forged steel material, :

EN 10028-2: 2009 Flat products made of steels for pressure purposes. Non-alloy and alloy steels with specified elevated temperature properties

STEEL MAKING of 1.7336 forging parts

The steel shall be produced by an electric furnace process or one of the basic oxygen processes. The steel shall be fully killed. The steel products shall be forged or rolled.

FOllowing is chemical compostion of 1.7336, 13CrMoSi5-5,13CrMoSi5-5, 13CrMoSi55 forged steel rings

C max 0.17

Si 0.5 - 0.8

Mn 0.4 - 0.65

Ni max 0.3

P max 0.015

S max 0.005

Cr 1 - 1.5

Mo 0.45 - 0.65

N max 0.012

Cu max 0.3

Following of 1.7336 forging parts mechanical property :

Nominal thickness (mm): to 60

Rm - Tensile strength (MPa) (+NT) 510-690

Nominal thickness (mm): to 60 60 - 100

Rm - Tensile strength (MPa) (+QT) 510-690

Nominal thickness (mm): to 60

ReH - Minimum yield strength (MPa) (+NT) 310

Nominal thickness (mm): to 60

ReH - Minimum yield strength (MPa) (+QT) 400

KV - Impact energy (J) transverse, (+NT)

0° Min 27J

+20°Min 34J

KV - Impact energy (J) transverse, (+QT)

-20°MIn 27J

0°MIn 34J

+20°MIn 40J

FOllowing is inspection standard of 1.7336 Forged steel material

ASTM E10-12: Standard Test Method for Brinell hardness of Metallic Materials;

ASTM A370-12: Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM E23-07a: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials;

AMS 2315G: Determination of Delta Ferrite Content,

ASTM E45-05: Standard Test Methods for Determining the Inclusion Content of Steel,

ASTM E112-10: Standard Test Methods for Determining Average Grain Size,

ASTM E837: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method,

Qualification of manufacturing procedure of 1.7336 forging parts

The Manufacturing Process Plan (MPP) shall be submitted to the approval of clients Material

& Process Engineering dept. clients before qualification procedure begins. It shall detail at least

the following:

• type of ingot (supplier, manufacturing process, dimensions, and tests to beperformed);

• forging process;

• heat treatment process;

• tests on component.

In general, dissection of the first piece within the terms detailed in the part specification is required.

This activity may be omitted, upon decision of clients, if the supplier has already proven to be able to successfully produce components of similar shape, dimensions and manufacturing

process.

Welcome your inquiry of 1.7336, 13CrMoSi5-5,13CrMoSi5-5, 13CrMoSi55 forging forged steel parts