Description

Jiangsu Liangyi is professional manufacturer of AMS 4675 open die forging parts and seamless rolled steel forged rings from china

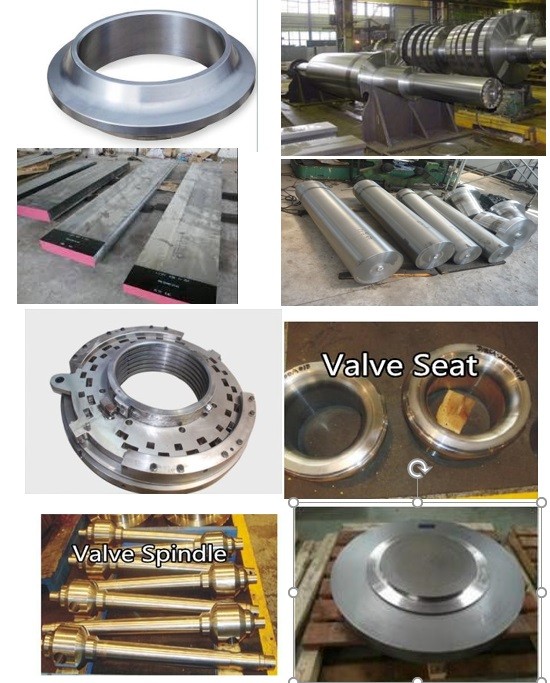

Following is the shape of AMS 4675 forging steel material that we could do is:AMS 4675 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 4675 Forged forging steel rings seamless rolled rings,AMS 4675 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 4675 Forged Forging Steel Discs Disks Blocks plates,AMS 4675 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 4675 material that is used in following industry

AMS 4675 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AMS 4675 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

AMS 4675 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

AMS 4675 forged steel Mechanical Seal Discs

AMS 4675 Forged Forging Steel Butterfly Valve Main Shafts Spindles

AMS 4675 Forged Forging Marine Ship Boat Propeller Shafts

AMS 4675 Forged Forging Swept branches outlets steel fittings swept saddles

AMS 4675 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AMS 4675 Forged Forging Gas Air Compressor Rotor

AMS 4675 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

AMS 4675 Forged Forging venturi cone meter Body Bodies Blocks

AMS 4675 Forged Forging Steel gate valves Body Bodies bespoke flat bars

AMS 4675 forging forged steel Couplings

AMS 4675 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

AMS 4675 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AMS 4675 Forged Forging Steel double studded adapter flange

AMS 4675 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

AMS 4675 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

AMS 4675 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

AMS 4675 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

AMS 4675 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

AMS 4675 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

AMS 4675 Forged Forging forge Steel transition Cone

AMS 4675 Forged Forging Steel Pressure Vessel Reactor Nozzles

AMS 4675 is popular nickel-copper alloy that is hardened via cold working. It exhibits high strength, excellent resistance to a variety of acidic and alkaline environments, and good ductility and thermal conductivity. Monel 400® is suitable for temperatures ranging from subzero to 1,000°F (538°C).

AMS 4675 is a single-phase solid-solution nickel-copper alloy with excellent corrosion resistance to a wide range of media. Typical applications include:

- propeller and pump shafts for seawater service

- industrial heat exchangers

- brine heaters and evaporator bodies in seawater desalination plants

- feed-water and steam generator tubing in power plants

- plants for uranium refining and isotope separation in the production of nuclear fuel

- sulphuric and hydrofluoric acid alkylation plants

- splash-zone sheathing in offshore structures

- cladding for crude oil distillation columns

AMS 4675 is virtually immune to chloride ion stress corrosion cracking in typical environments. Generally, its corrosion resistance is very good in reducing environments, but poor in oxidizing conditions.

AMS 4675is resistant to most alkalis, salts, waters (including saline or brackish), food products, organic substances and atmospheric conditions at normal and elevated temperatures.

This alloy is not useful in highly oxidizing acids, such as nitric and nitrous. It is resistant to sulfuric acid in concentrations to 80% and in hydrochloric solutions in concentrations to 20%.

Oxidizing impurities such as ferric chloride, ferric sulfate, chromates, nitrates, peroxides, and cupric salts, can cause attack in a medium which would otherwise be relatively mild for the alloy.

FOllowing is chemical compostion of AMS 4675 forged steel rings

Nickel (plus Cobalt) ……………………………………………. 63 % Minimum

Copper ……………………………………………………………… 28. 0 – 34.0 %

Carbon ……………………………………………………………… 0.3 % Maximum

Manganese ……………………………………………………….. 2.0 % Maximum

Iron …………………………………………………………………… 2.5% Maximum

Sulfur ………………………………………………………………… 0.024% Maximum

Silicon ……………………………………………………………….. 0.5% Maximum

Following of AMS 4675 forging parts heat treatment Delivery condition :

Tensile strength ……….. 75,000 – 95,000 psi

Yield strength ………….. 25,000 – 50,000 psi

Elongation ………………. 60 – 35 %

The purity grade of the AMS 4675 forged steel material is to be determined per DIN 50602-K1.The following value is to be kept in this case(on 1000 mm²)-Sum characteristics value K1:≤2.0

For determination 4 tests per heat are to be employed at least Depending on the appearance of the analysed microsections also higher K1-Values may possibly be Tolerated.Content of Delta-Ferrite Delta ferrite content:<5% (Determined in a manner consistent with the evaluation technique described in ASTM E 45/Method A,"Worst Field Method"at V=100,specimen orientation:longitudinal.Thedistribution and size of delta ferrite must be such that it does not result in indication in magnetic particle testing of the ready-machined surface.)

The following NDT inspections shall be performed after all heat treatments are performed

Visual inspection of all AMS 4675 forging round bars

UT of all AMS 4675 flat bars as per SEP 1923,inspection number D3 or D2 with dual (twin crystal search unit.100% of the volume shall be examined with the stipulated ecording level

Criteria stipulated in SEP 1923 quality class 2 b shall be applied with following modification:EE(single echo)and VE(numerous single echoes)without extension ≥2mm KSR are not permitted Defects above the recording limit shall be marked and it shall be ensured that these AMS 4675 forging flat bars are not included in the lot delivered.

Welcome your inquiry of AMS 4675 forging forged steel parts