Description

Jiangsu Liangyi professional manufacturer of 2.4652(2.4631,NiCr20TiAl) open die forging parts and seamless rolled steel forged rings from china

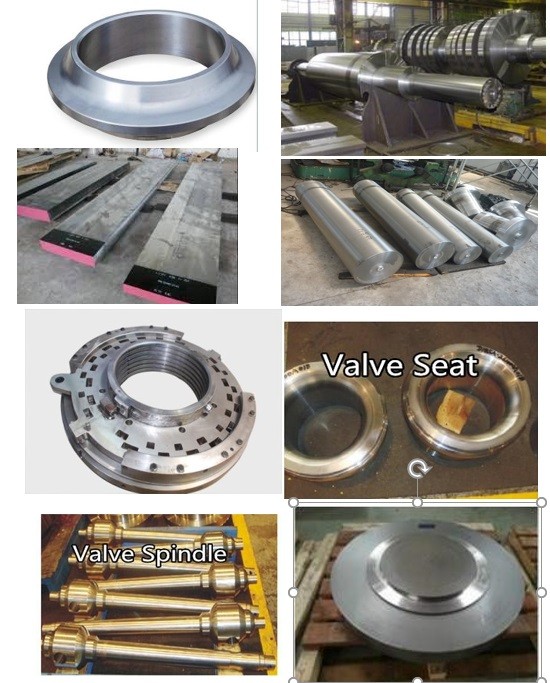

Following is the shape of 2.4652(2.4631,NiCr20TiAl) forging steel material that we could do is: 2.4652 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4652 Forged forging steel rings seamless rolled rings, 2.4652 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiCr20TiAl Forged Forging Steel Discs Disks Blocks plates,2.4631 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4652,NiCr20TiAl material that is used in following industry

2.4652 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4631 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

2.4652 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

NiCr20TiAl Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

NiCr20TiAl Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4631 Engine exhaust valves and spindles,Automobile exhaust valves

2.4631 forged steel die casting inserts and cores

2.4631 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4652 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

2.4652,NiCr20TiAl Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

2.4652,NiCr20TiAl Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4631 is nickel-based superalloy consisting mostly of nickel and chromium. It is a material with high nickel and can be precipitated and hardened by aging. In addition, elements such as titanium, aluminum and carbon in 2.4652(2.4631,NiCr20TiAl) make the material highly durable mechanically. This special alloy, which is also defined as W. Nr. 2.4952, can be used at temperatures like 815 ° C thanks to the elements in it.

2.4652(2.4631,NiCr20TiAl) is melted at high frequency and cast in this way. The material that is given a clean structure and poured by the ESR (Electroslag Remelting) method is generally preferred for forging production. There are also vacuum refined versions of 2.4652(2.4631,NiCr20TiAl) material available.

2.4652(2.4631,NiCr20TiAl)is often used in gas turbines, gas turbine discs, bolts, special bolts, pipe support parts of nuclear boilers, some places where casting is made, mold entry points of casting, vehicle exhaust valves and some parts of internal combustion engines.

FOllowing is production standard of 2.4652(2.4631,NiCr20TiAl) forged parts

EN 10269: 1999 Steels and nickel alloys for fasteners with specified elevated and/or low temperature properties

EN 10090: 1998 Valve steels and alloys for internal combustion engines

EN 10302: 2008 Creep resisting steels, nickel and cobalt alloys

Chemical composition of 2.4652(2.4631,NiCr20TiAl) forging turbine parts is as follows

Chemical Composition

Element Min % Max %

C 0.04 0.1

Si – 1

Mn – 1

S – 0.015

Ag – 0.0005

Al 1 1.8

B – 0.008

Bi – 0.0001

Co – 2

Cr 18 21

Cu – 0.2

Fe – 1.5

Pb – 0.002

Ti 1.8 2.7

Ni balance

mechanical property of for 2.4652(2.4631,NiCr20TiAl) forged round bars is as follow

Mechanical properties of steel NiCr20TiAl (2.4952)

Rm - Tensile strength (MPa) (+AT) 1100-1400

Rm - Tensile strength (MPa) (+P) MIN 1000

Rp0.2 0.2% proof strength (MPa) (+AT) MIN 725

Rp0.2 0.2% proof strength (MPa) (+P) MIN 600

KV - Impact energy (J) longitud., (+AT) +20°MIN 20

Removal of test samples of 2.4652(2.4631,NiCr20TiAl) forged round bars

Unless otherwise indicated on the drawing or in the specification for the part , removal is to be effected as follows :

- longitudinal if the section can be inscribed in a circle with diameter < 1 0 0 mm

- transverse if the section can be inscribed in a circle with diameter ≥ 1 0 0 mm

- tangential for 2.4652(2.4631,NiCr20TiAl) forged rings or disks

In order to make forging and make heat treatment Stainless Steel 2.4652(2.4631,NiCr20TiAl)forging material, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m