Description

Jiangsu Liangyi professional manufacturer of Z20CDNbV11,Z 20 CDNbV 11 open die forging forged parts and seamless rolled rings factory from china

Z20CDNbV11 is Creep resisting steel, hardened and tempered. Usual upper temperature limit for continuous operating at 580°C. Components featuring elevated high-temperature strength for use in thermal engines and power plants, such as turbine blades, turbine discs, screws, bolts, pins and shafts.

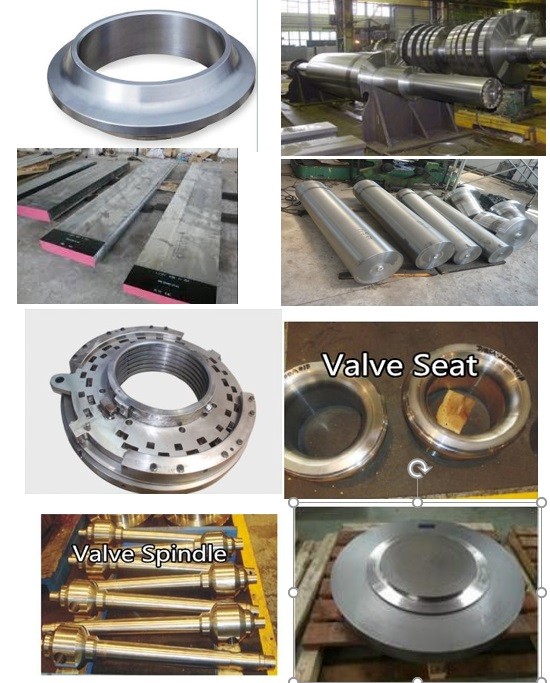

Following is the shape of Z20CDNbV11,Z 20 CDNbV 11 forging steel material that we could do is:Z20CDNbV11,Z 20 CDNbV 11 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Z20CDNbV11,Z 20 CDNbV 11 Forged forging steel rings seamless rolled rings,Z20CDNbV11,Z 20 CDNbV 11 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Z20CDNbV11,Z 20 CDNbV 11 Forged Forging Steel Discs Disks Blocks plates,Z20CDNbV11,Z 20 CDNbV 11 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.Z20CDNbV11,Z 20 CDNbV 11 Forged Forging Steel Gas Steam Turbine Rotors Shafts,Z20CDNbV11,Z 20 CDNbV 11 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars,Z20CDNbV11,Z 20 CDNbV 11 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,, Z20CDNbV11 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,,Z20CDNbV11,Z 20 CDNbV 11 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

We could produce Z20CDNbV11,Z 20 CDNbV 11 forged material with diameters ranging from 100MM to 6000MM and with weights from 10KGS to 15000KGS

We could supply Z20CDNbV11 forging turbine material as per the standard of EN10204-3.1 or EN10204-3.2 of third party such TUV, DNV,BV,SGS and so on

Following is production process for Z20CDNbV11 forged Turbine Blades steel Flat Bars

Forging process flow quality control: Raw material steel ingot into warehouse(test the chemical content) → Cutting→ Heating(Furnace temperture test) → Heat treatment after forging(Furnace temperture test) Discharge the furnace(blank inspection)→ Machining→ Inspection(UT,MT,Visal diamention, hardness)→ QT→ Inspection(UT, mechanical properties, hardness, grain size)→ Finish machining→ Inspection (dimension)→ Packing and Marking(steel stamp, mark)→ Storage Shipment

We produce Z20CDNbV11 forged steel turbine blade material as per standard of NF A 35-558-1983

C (%): 0.18 ~ 0.25

Si (%): 0.10 ~ 0.50

Mn (%): 0.30 ~ 0.80

P (%)≤: 0.025

S (%)≤: 0.015

Cr (%): 10.0 ~ 12.0

Ni (%): ≤ 1.00

Mo (%): 0.50 ~ 1.00

Nb (%): 0.25 ~ 0.55

V (%): 0.10 ~ 0.30

N (%): 0.05 ~ 0.10

Following is mechnical property of Z20CDNbV11 forged turbine blade flat bars Rectangles Bars

QT1: Rp0,2 = min. 600Mpa, Rm = 800 – 950Mpa, KV min. 27J

QT2: Rp0,2 = min. 700Mpa, Rm = 900 – 1050Mpa, KV min. 20J

We have following inspection equipment to inspect Z20CDNbV11 forging steel parts

Spectrograph,ut device,tensile and compact test machine,metalloscope,outside micrometer,bore dial indicator,hardness test machine

Welcome your inquiry of Z20CDNbV11 forging forged steel parts