Description

Jiangsu Liangyi is professional manufacturer of 1.3912 ,Ni 36 open die forging parts and seamless rolled steel forged rings from china

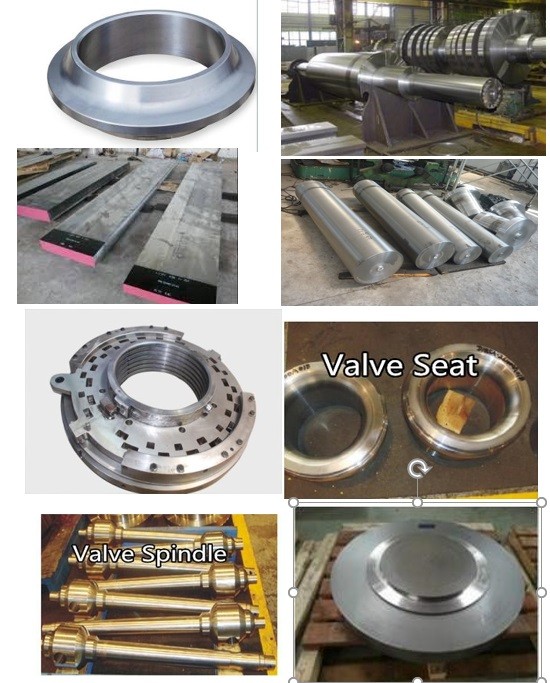

Following is the shape of 1.3912 ,Ni 36 forging steel material that we could do is:Ni 36 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Ni 36 Forged forging steel rings seamless rolled rings,1.3912 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.3912 Forged Forging Steel Discs Disks Blocks plates,Ni 36 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

1.3912 ,Ni 36 is a binary nickel-iron alloy with 36% nickel that is known for its low coefficient of expansion. It has a very low thermal expansion coefficient at room temperature and minimal variation at cryogenic temperatures, making it ideal for use in precision components. It is also used in applications where dimensional stability is critical such as in tools for the production of composite materials used in aerospace and automotive applications.

All our 1.3912 ,Ni 36 forged material must give the material a required purity necessary for the application in following melting methods

one is triple melted material,VIM+ESR+VAR., the another one is double melted material,VIM+VAR.

FOllowing is chemical compostion of Ni 36 forged steel rings

Ni 35,00 - 38,00

Co max. 1,00

Mn max. 0,60

Cr max. 0,50

Mo max. 0,50

Si max. 0,35

C max. 0,10

P max. 0,025

S max. 0,025

Fe Rest

Following of Ni 36 forging parts heat treatment mechanical property Delivery condition :

Metallurgical Condition Annealed, Descaled

Yield Strength KSI (MPa) 38 (260) Max

Tensile Strength KSI (MPa) 63 (430) Max

Hardness HB 135

Elongation 50mm >30% (Typical 40%)

ALl our 1.3912 ,Ni 36 forged bars shall issue a certificate of test according to SAE AMS 2154 and EN 10204, cert. 3.1

An inspection certificate 3.1 according EN 10204 of our 1.3912 ,Ni 36 forged bars should have following

purchase order, item, serial n°, drawing number and number of the technical purchasing

specification

material designation

heat n° and heat analysis

method of melting

manufacturing procedure

heat treatment: cooling method (rates and mean of cooling) and measured temperatures.

All heat treatment conditions have to be quoted in a graphic temperature against time

sequence (including all re-heat-treatments). Reports including only average holding

temperatures and times are acceptable.

results of metallographic analysis

mechanical tests certificates, including single values

results and recording of NDT. A dedicated certificate for each performed NDT is required

dimensional report (tabular or graphically) complete of a certificate of compliance

Welcome your inquiry of 1.3912 ,Ni 36 forging forged steel parts