Description

Jiangsu Liangyi professional manufacturer of 254SMO,UNS S31254,254 SMO,Alloy 254SMO, SMO 254, SMO254 open die forging parts and seamless rolled steel forged rings from china

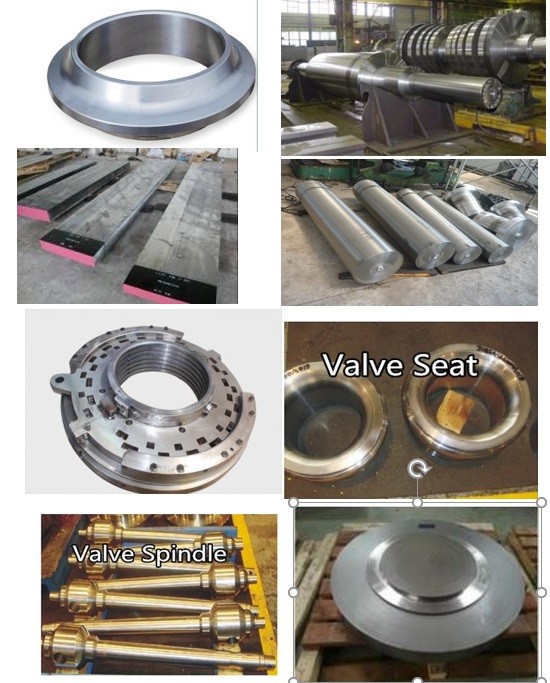

Following is the shape of 254SMO,Alloy 254SMO, 254 SMO,UNS S31254 forging steel material that we could do is:254SMO Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Alloy 254SMO Forged forging steel rings seamless rolled rings,254 SMO Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS S31254 Forged Forging Steel Discs Disks Blocks plates,254SMO Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 254SMO,Alloy 254SMO, 254 SMO,UNS S31254 material that is used in following industry

Alloy 254SMO forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

254 SMO Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Alloy 254SMO Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

254 SMO Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

254SMO Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

254 SMO Forged Forging Steel nuclear Power

Alloy 254SMO Forged Forging Steel Butterfly Valve Main Shafts Spindles

254 SMO Forged Forging Swept branches outlets steel fittings swept saddles

254SMO Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Alloy 254SMO Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

254 SMO Forged Forging venturi cone meter Body Bodies Blocks

UNS S31254 Forged Forging Steel gate valves Body Bodies bespoke flat bars

254SMO forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

254SMO forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Alloy 254SMO Forged Forging Steel double studded adapter flange

Alloy 254SMO Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS S31254 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Alloy 254SMO Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Alloy 254SMO Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Alloy 254SMO Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Alloy 254SMO Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

254 SMO Forged Forging forge Steel transition Cone

UNS S31254 Forged Forging Steel Pressure Vessel Reactor Nozzles

254SMO forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

254SMO is super austenitic stainless steel grade with 0.2% nitrogen additions, particularly designed to be cost effective. The 18% nickel and 0.7% copper additions combined with the chromium and molybdenum additions enhance the performance of the steel in many corrosive solutions encountered for example in chemical and petrochemical processes or chloride containing solutions.

The alloy is also seawater resistant and has extensively been used in offshore applications (It is not recommended for use in stagnant seawater applications with temperatures higher than 30°C (86°F).

FOllowing is chemical compostion of Alloy 254SMO forged steel rings

Element Wrought Castings

Carbon ≤0.020 ≤0.025

Chromium 19.5-20.5 19.5-20.5

Nickel 17.5-18.5 17.5-19.5

Molybdenum 6.0-6.5 6.0-7.0

Nitrogen 0.18-0.22 0.180-0.240

Copper 0.50-1.00 0.50-1.00

Sulfur ≤0.010 ≤0.010

Phosphorus ≤0.030 ≤0.045

Silicon ≤0.80 ≤1.00

Manganese ≤1.00 ≤1.20

Iron Balance Balance

Following of 254SMO forging parts heat treatment nechanical property Delivery condition :

0.2% Proof Stress 300 N/mm2 43.5ksi

Tensile Strength 650 N/mm2 94.25ksi

Elongation, 5.65√S0 and 4D 35%

Reduction of Area 50%

Hardness (Brinell) <270

Following is inspection standard of 254 SMO forged parts

ASTM A604 Standard test methods for macroetch testing of consumable electrode

remelted steel bars and billets

ASTM E112 Standard test methods for determining average grain size

EN ISO 6892-1:20 Metallic materials -Tensile testing -Part 1:Method of test at ambient temperature

ISO 204:2009 Metallic materials -Uniaxial creep testing in tension -Method of test

EN 10204 Metallic products -Types of inspection documents

EN ISO/IEC 17050:2004 Conformity assessment -Supplier's declaration of conformity -General requirement

All our UNS S31254 forging material shall be thoroughly worked,homogenous and free from blisters, cracks and injurious slag inclusions.

Material certification to EN10204 Type 3.1 of finish 254SMO,Alloy 254SMO, 254 SMO,UNS S31254 forged material should be issued as per following

Material certificate,per batch,referred to this specification are issued by the manufacturershall include as minimum:

Order No.

Grade of material

Cast no.and heat treatment no.

Melting and refining process.

Certified chemical analysis.

Certified record of mechanical properties including impact test.

Certificate of Ultrasonic Test

Material certification must include a statement that material meets the requirements of NACE MR0175.Calibration of heat treatment furnaces and the Equivalent Round of the Qualification test coupon comply with API Spec 6A

Welcome your inquiry of 254SMO,Alloy 254SMO, 254 SMO,UNS S31254 forging forged steel parts

Following is the shape of 254SMO,Alloy 254SMO, 254 SMO,UNS S31254 forging steel material that we could do is:254SMO Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Alloy 254SMO Forged forging steel rings seamless rolled rings,254 SMO Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS S31254 Forged Forging Steel Discs Disks Blocks plates,254SMO Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 254SMO,Alloy 254SMO, 254 SMO,UNS S31254 material that is used in following industry

Alloy 254SMO forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

254 SMO Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Alloy 254SMO Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

254 SMO Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

254SMO Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

254 SMO Forged Forging Steel nuclear Power

Alloy 254SMO Forged Forging Steel Butterfly Valve Main Shafts Spindles

254 SMO Forged Forging Swept branches outlets steel fittings swept saddles

254SMO Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Alloy 254SMO Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

254 SMO Forged Forging venturi cone meter Body Bodies Blocks

UNS S31254 Forged Forging Steel gate valves Body Bodies bespoke flat bars

254SMO forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

254SMO forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Alloy 254SMO Forged Forging Steel double studded adapter flange

Alloy 254SMO Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS S31254 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Alloy 254SMO Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Alloy 254SMO Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Alloy 254SMO Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Alloy 254SMO Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

254 SMO Forged Forging forge Steel transition Cone

UNS S31254 Forged Forging Steel Pressure Vessel Reactor Nozzles

254SMO forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

254SMO is super austenitic stainless steel grade with 0.2% nitrogen additions, particularly designed to be cost effective. The 18% nickel and 0.7% copper additions combined with the chromium and molybdenum additions enhance the performance of the steel in many corrosive solutions encountered for example in chemical and petrochemical processes or chloride containing solutions.

The alloy is also seawater resistant and has extensively been used in offshore applications (It is not recommended for use in stagnant seawater applications with temperatures higher than 30°C (86°F).

FOllowing is chemical compostion of Alloy 254SMO forged steel rings

Element Wrought Castings

Carbon ≤0.020 ≤0.025

Chromium 19.5-20.5 19.5-20.5

Nickel 17.5-18.5 17.5-19.5

Molybdenum 6.0-6.5 6.0-7.0

Nitrogen 0.18-0.22 0.180-0.240

Copper 0.50-1.00 0.50-1.00

Sulfur ≤0.010 ≤0.010

Phosphorus ≤0.030 ≤0.045

Silicon ≤0.80 ≤1.00

Manganese ≤1.00 ≤1.20

Iron Balance Balance

Following of 254SMO forging parts heat treatment nechanical property Delivery condition :

0.2% Proof Stress 300 N/mm2 43.5ksi

Tensile Strength 650 N/mm2 94.25ksi

Elongation, 5.65√S0 and 4D 35%

Reduction of Area 50%

Hardness (Brinell) <270

Following is inspection standard of 254 SMO forged parts

ASTM A604 Standard test methods for macroetch testing of consumable electrode

remelted steel bars and billets

ASTM E112 Standard test methods for determining average grain size

EN ISO 6892-1:20 Metallic materials -Tensile testing -Part 1:Method of test at ambient temperature

ISO 204:2009 Metallic materials -Uniaxial creep testing in tension -Method of test

EN 10204 Metallic products -Types of inspection documents

EN ISO/IEC 17050:2004 Conformity assessment -Supplier's declaration of conformity -General requirement

All our UNS S31254 forging material shall be thoroughly worked,homogenous and free from blisters, cracks and injurious slag inclusions.

Material certification to EN10204 Type 3.1 of finish 254SMO,Alloy 254SMO, 254 SMO,UNS S31254 forged material should be issued as per following

Material certificate,per batch,referred to this specification are issued by the manufacturershall include as minimum:

Order No.

Grade of material

Cast no.and heat treatment no.

Melting and refining process.

Certified chemical analysis.

Certified record of mechanical properties including impact test.

Certificate of Ultrasonic Test

Material certification must include a statement that material meets the requirements of NACE MR0175.Calibration of heat treatment furnaces and the Equivalent Round of the Qualification test coupon comply with API Spec 6A

Welcome your inquiry of 254SMO,Alloy 254SMO, 254 SMO,UNS S31254 forging forged steel parts