AISI 4145H MOD Forged Hollow bars for Drill collars for italy clients

These days, we received one order of AISI 4145H MOD Forging Forged Hollow bars for Drill collars for italy clients, Following is technical requirement of AISI 4145H forged hollow bars of our clients

|

Chemical Composition of AISI 4145H Forged hollow bars |

|||

|

Element |

Composition |

||

|

C |

0.43 - 0.48 % |

||

|

Mn |

0.75 - 1.0 % |

||

|

P |

<= 0.035 % |

||

|

S |

<= 0.040 % |

||

|

Si |

0.15 - 0.30 % |

||

|

Cr |

0.80 - 1.1 % |

||

|

Mo |

0.15 - 0.25% |

||

|

Mechanical Properties of AISI 4145H mod forged hollow bars |

|||

|

Test Location |

Refer to Table 1 |

||

|

Yield Strength @ 0.2 % |

120,000 psi min |

||

|

Tensile Strength% |

140,000 psi min |

||

|

Elongation% 2" Gauge Length |

13% min |

||

|

Impact Test Temperature |

70 ºF (RT) |

-4 ºF (± 5 °F) |

|

|

Impact Value (Avg. of 3 specimens) |

40 ft-lbs Min |

31 ft-lbs Min |

|

|

Impact Value (Min. single value) |

35 ft-lbs min |

24 ft-lbs min |

|

|

Surface Hardness (BHN) |

285 BHN min |

||

|

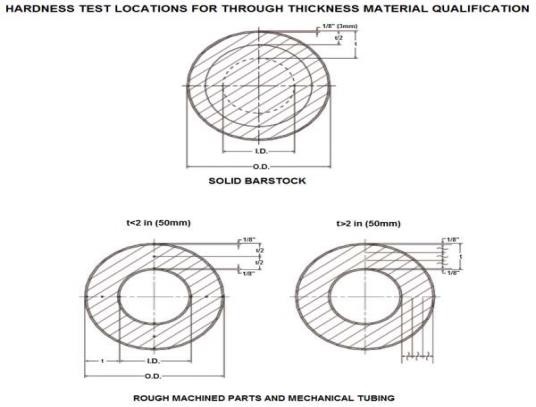

Through Wall Hardness (BHN) |

285 BHN (Refer to Figure 1 & Table 2) |

||

|

Straightness |

1/160 inch per ft |

||

|

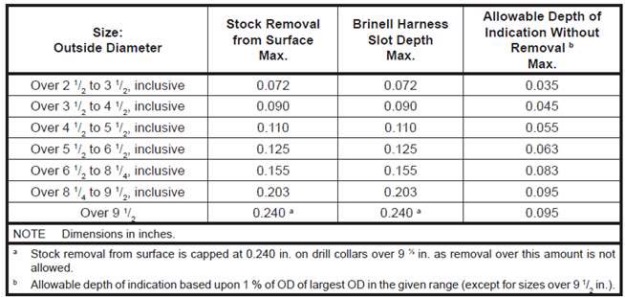

Surface Finish & OD Tolerances of AISI 4145 forged hollow bars |

|||

|

Size Outside Diameter |

Size tolerance inclusive |

Out of Roundness |

|

|

max |

min |

||

|

2-1/2” to 3-1/2” |

3/64” |

0 |

0.035” |

|

3-1/2” to 4-1/2” |

1/16” |

0 |

0.046” |

|

4-1/2” to 5-1/2” |

5/64” |

0 |

0.058” |

|

5-1/2” to 6-1/2” |

1/8” |

0 |

0.070” |

|

6-1/2” to 8-1/4” |

5/32” |

0 |

0.085” |

|

8-1/4” to 9-1/2” |

3/16” |

0 |

0.100” |

|

Over 9-1/2” |

¼” |

0 |

0.120” |

|

Markings |

Heat Number and Bar Number must be Stenciled on each bar |

||

|

Bore Eccentricity Allowed |

1/16" |

||

|

NDT Required |

• The Ultrasonic Inspection reference standard shall be ASTM E 213. • Magnetic Particle inspection reference standard shall be ASTM E3024. • Liquid Penetrant Inspection reference standard shall be ASTM E165. • Eddy Current Inspection reference standard shall be either ISO 10893 or ASTM E309 |

||

|

Destructive Tests Required |

• Hardness measurement standard shall be ASTM A370 and ASTM E10. • Impact strength requirements reference shall betaken from ASTM A370 and ASTM E23. • Tensile Strength requirements shall betaken from ASTM A 370. |

Table-1 - Test Location

|

Bar OD |

Testing Location |

|

Through 7-1/2” OD |

1” Below the surface and Mid-Radius |

|

Over 7-1/2” OD |

1” Below the surface and 1-3/4” above the center |

Table-2 - Reference ID for Through Wall Hardness Test

|

Bar OD |

ID |

|

4-3/4” to 6-1/2” |

2-1/2” |

|

6-3/4” to 7-1/2” |

2-9/16 |

|

7-3/4” to 8-1/2” |

2-13/16” |

|

8-3/4” to 10” |

3” |