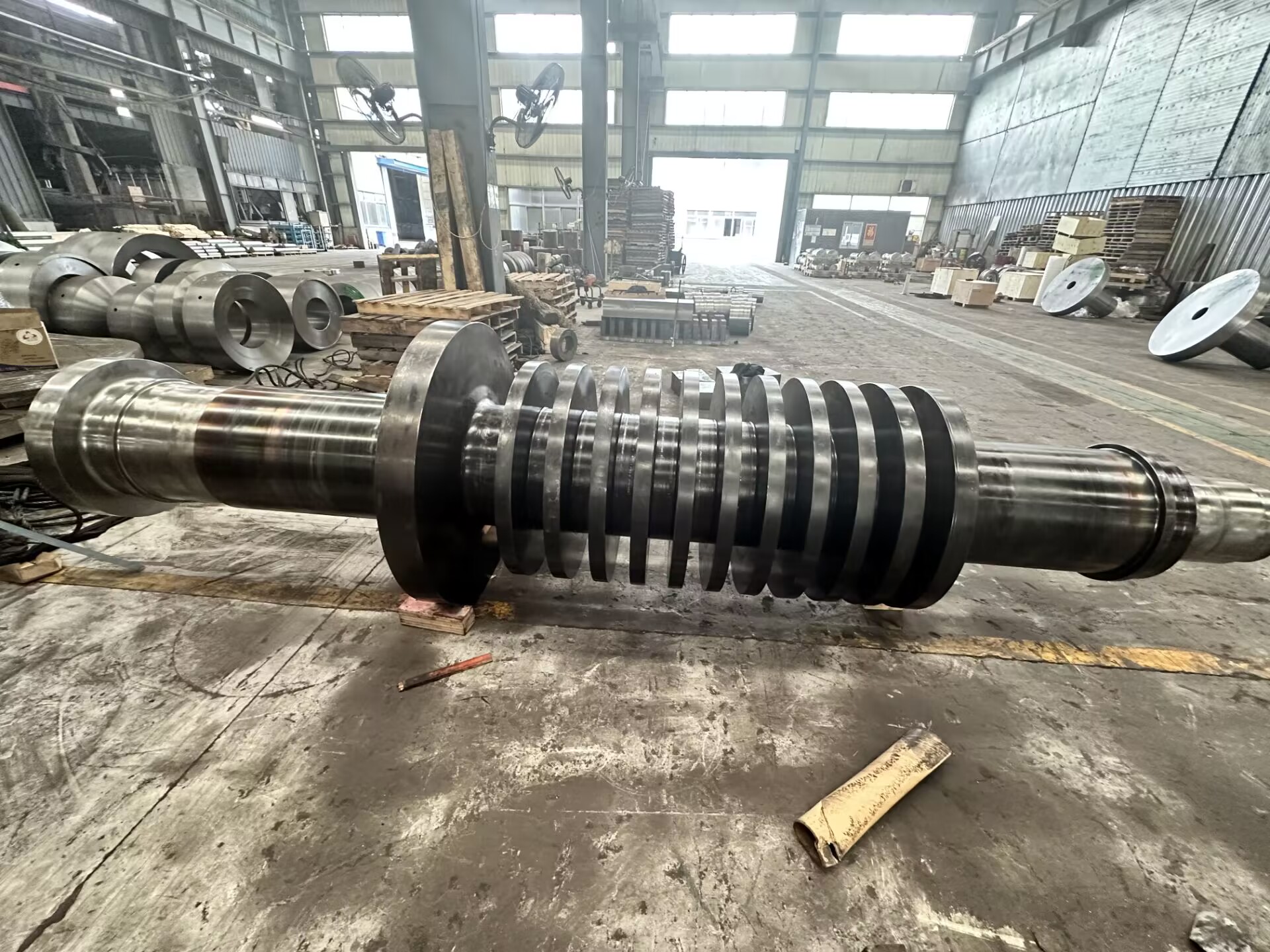

1.6931 26NiCrMoV 8-5 Forging Steel Steam Turbine Rotor Shafts

These days, we produce 1.6931,26NiCrMoV8-5 Forging Steel Gas Steam Turbine Rotor Shafts for our brazil clients

The forge 26NiCrMoV8-5 rotor shafts shall be furnished with a rough machining in accordance with the dimensions specified in the clients drawing N°AF00289145

Manufacture process of 1.6931 forged turbine rotor shafts:

Shall be in accordance with the recommendations described in the drawing.N°AF00289145 ,taking in consideration all the recommendations for the melting process,vacuum treatment,discard and forging process.

Heat treatment: The heat treatment for the forged rotor shall consist of quench and temper for a suitable temperature and time according the class of steel for guarantee the required mechanical properties specified in the attached drawing N°AF00289145

Mechanical Properties of 26NiCrMoV8-5 forging rotor shafts :

The forged rotor material after the final heat treatment shall comply with the mechanical values specified in the attached drawing 26NiCrMoV 8-5

| MECHANICAL PROPERTY REQUIREMENTS AT 23 ℃ | |||||||

| POSITION | RIM &CORE | ||||||

| PROPERTY | UNIT | RANGE | ORIENTATION | ||||

| TENSIL STRENGTH |

PSI (MPa) |

99325 min. (685 min.) |

rad./tang | ||||

|

YIELD STRENGTH 0.2%OFFSET |

PSI (MPa) |

78300-92800 (540-640) |

rad./tang | ||||

|

ELONGATION IN 2"OR 50mm |

% | 14 min. | rad./tang | ||||

| REDUCTION OF AREA | % | 50 min. | rad./tang | ||||

|

ABSORVED IMPACT ENERGY |

ft-lbf ()) |

30 min. (40 min.)rim |

rad./tang | ||||

| FATT(50% | ℃ | +10 max. | rad./tang. | ||||

Non destructive test of 26NiCrMoV8-5 forging rotor shaftgs:

The forging shall be free of cracks,seams,laps,shrinkage and similar imperfections.

An ultrasonic examination shall be made on the machined forging in accordance with practice A418/A418M to demonstrate freedom from rejectable internal indications.

The forging shall be free of surface and subsurface defects like cracks detected by magnetic particle examination in accordance with practice A275/A275M and dye penetrant in accordance with practice ASTM E-165.

Certification and reports of finished 26NiCrMoV8-5 forged turbine rotor shafts:

-Forging identification number.

-Heat number.

-Final product chemical analysis.

-Results of all acceptance test for mechanical properties and notch toughness.

-Results of all nondestructive examinations and if this is applicable the sketches indicating the location and orientation of all recordable indications,

-Final heat treatment cycle including austenizing and tempering temperatures,holding times and cooling methods

MATERIAL MANUFACTURE of requirement of 1.6931 forging rotor shafts

MELTING PROCESS:Electric arc,electric induction or consumable-electrode

VACUUM DEGASSING:Remove all objetionable gases,particulary hidrogen

Chemical compostion of 26NiCrMoV 8-5 forging steam turbine rotor shafts

| MATERIAL | CHEMICAL COMPOSITION | |

|

STEEL FOR MONOBLOC ROTOR FORGINGS According to the chemical composition showed |

%C | 0.22-0.28 |

| %Si | 0.3 max | |

| %Mn | 0.30-0.60 | |

| %P | 0.015 max | |

| %S | 0.010 max. | |

|

OTHER: (EQUIVALENT) -DIN SEW 555 N°1.6931 26NiCrMoV8-5 |

%Cr | 1.20 to 1.60 |

| %Ni | 1.80-2.30 | |

| %Mo | 0.30-0.55 | |

| %V | 0.07 max. | |

| %Fe | BALANCE | |

FORGING PROCESS:Hot mechanical work,mantain the axial center of the forging in common with the axial center of the ingot for guarantee the machined dimensions of this drawing."

COOLING PRIOR TO HEAT TREATMENT;After forging,cool to accomplish transformation.

PRELIMINARY HEAT TREATMENT:Complete austenization according the material,cool to accomplish transformation.

PRELIMINARY MACHINING:Prior to heat treatment for mechanical properties

HEAT TREATMENT FOR MECHANICAL PROPERTIES:Quench and temper for a suitable temperature and time according to the · material for quarantee the required mechanical properties."

MACHINING TO PURSCHASER'S REQUIREMENTS FOR SHIPMENT:According the dimenslons and tolerances specified in this drawing.

STRESS RELIEF of 1.6931 forged rotor shaftsd:After machining for shipment 56°C below the final tempering temperature but not less tan 550℃

"NON DESTRUCTIVE TEST of 1.6931 forged rotor shafts: The forging shall be free of cracks,seams,laps,shrinkage and similar imperfections detected by ultrasonic examination ASTM A418/A418M,magnetic particle ASTM A275/A275M and dye penetrant.ASTM E165."