API 6A CRA Inconel 718 Round Bars For UAE Clients

These days, we produce some API 6A CRA Inconel 718 Round Bars For UAE Clients

FOllowing is technical manual of Inconel 718 Round Bars For UAE Clients

Reference production standard of inconel 718 round bars

API Standard 6ACRA

First Edition.August 2015

Addendum 3,2,1/Errata 3,2,1

Material designation 120K

API Speciflcatlon 6A

Twenty-first Edition,November 2018-PSL4 Addendum 3,2,1/Errata 4,3,2,1

ANSI/NACE MR0175/ISO15156-3:2015

ANSI/NACE MR0103/ISO17945:2015

MS-011559-(05,55)-(01)Base Number Rev.33 MS-011559-(06,56)-(01)Base Number Rev.33

100986456 Rev.AJ

100237403 Rev.BA

FMC M40910 Rev.W

FMC M40902 Rev,R

VGS 5.141.1 Rev.24 except para.14.1.1

VGS 5.541.1-120K Rev.31 except para 13.1.1 WN-301 Rev.Z except para.4.0

ES-MA-46-2 Rev.Q

BMS N201 Rev.AD

BMS N213 Rev.T

CSP-4 Rev.BN

UNS N07718

|

Chemical Composition(%) Chemical Composition Steelmaking Process:VIM+VAR |

Heat | No | |||||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Mo | Ni | Cu | Co | ||||||||||||||||||||||||||||

| 0.009 | 0.05 | 0,08 | 0.006 | 0,0005 | 18.1 | 3.00 | 53,4 | 0,05 | 0,21 | FVL512 | |||||||||||||||||||||||||||

| Ti | AI | Nb | B | Fe | N | Pb | Ta | O | Bi | ||||||||||||||||||||||||||||

| 0.91 | 0.47 | 4,99 | 0.0027 | 18.59 | 0.008 | <0,0003 | <0,020 | <0,0003 | <0,00003 | ||||||||||||||||||||||||||||

| Ca | Mg | Sn | Se | FL029* | |||||||||||||||||||||||||||||||||

| <0,0002 | 0.0011 | <0,0010 | <0,0003 | 501 | |||||||||||||||||||||||||||||||||

The macroetch examination of inconel 718 round bars

| The macroetch examination was performed on full transverse cross-section slices, | |||||||||||||||||||||||||||||||||||||

| representative of the top and bottom section of the remelted ingot. | |||||||||||||||||||||||||||||||||||||

| Class 1 | Freckles | Severity A | |||||||||||||||||||||||||||||||||||

| Class 2 | White Spots | Severity A | |||||||||||||||||||||||||||||||||||

| Class 3 | Radial Segregation | Severity A | |||||||||||||||||||||||||||||||||||

| Class 4 | Ring Pattern | Severity A | |||||||||||||||||||||||||||||||||||

| The material complies with the requirements of the macroetch examination acc.to API Standard 6ACRA-Para.4.2.1. | |||||||||||||||||||||||||||||||||||||

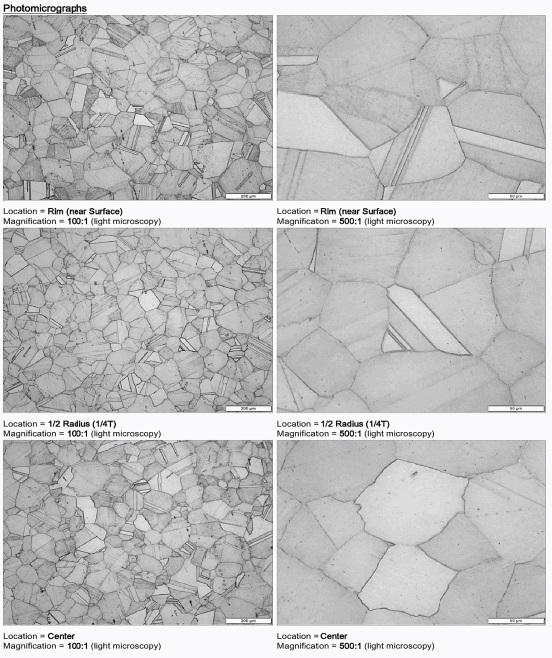

| Grain size evaluation of inconel 718 | |||||||||||||||||||||||||||||||||||||

|

Testing standard =ASTME112-13,ASTM

E930-18 Etchant =No.2 |

|||||||||||||||||||||||||||||||||||||

| Magnification =50:1,100:1,500:1 | |||||||||||||||||||||||||||||||||||||

| Location | Orientation | Structure | Average Grain Size | Duplex Distribution | |||||||||||||||||||||||||||||||||

| near Surface | longitudinal | Duplex ALA | ASTM no.4 | ALA ASTM no.0 | |||||||||||||||||||||||||||||||||

| 1/2 Radius(1/4T) | longitudinal | Duplex ALA | ASTM no.4.5 | ALA ASTM no.1 | |||||||||||||||||||||||||||||||||

| Center | longitudinal | Duplex ALA | ASTM no.4.5 | ALA ASTM no.0.5 | |||||||||||||||||||||||||||||||||

|

The material complies with API Standard 6ACRA-Para.4.2.2.2 No presence of topological duplex grain size conditions as defined per ASTM E1181. Microstructural examination for deleterious phases |

|||||||||||||||||||||||||||||||||||||

| Etchant =No.2 | |||||||||||||||||||||||||||||||||||||

| The microstructure is free from continuous networks of secondary phases along grain boundaries or other unusual microstructural features.The microstructure is free from acicular delta phase except in individual,isolated grains that are not representing of the bulk of the microstructure.There is no laves phase. | |||||||||||||||||||||||||||||||||||||

Mechanical properties

The QTC is a prolongation of the final heat treated bar.

The test specimen and the test method are in accordance with ASTM A370-21.

Tensile test properties

Specimen orientation =longitudinal

Specimen location=1/2 Radius(1/4T)

Specimen=standard size 12.5 mm [0.500 inch]diameter

Tensile test in delivery condition

|

Key H=hardest W=softest |

M=Mcl B=Bottom |

Yield Strength |

Uitimate Tensile Strength |

Elongation |

Reduction of Area |

||||||||||||||||||||||||||||||||

| Test no. | *Piece no. | Testing standard | Location |

Temp. °F |

YS0.2 | UTS | A4 | RoA | |||||||||||||||||||||||||||||

| KSI | KSI | % | % | ||||||||||||||||||||||||||||||||||

| 2228052-1 1 |

ASTM A 370-21 01.11.2021 |

L2 | 73 |

125-145 136.916 |

>=150 178.106 |

>=20 32 |

>=35 50 |

||||||||||||||||||||||||||||||

Impact test properties

Specimen orientation =longitudinal

Specimen location =1/2 Radius(1/4T)

Notch orientation=L-C

Specimen =standard size(Charpy-V)10×10 mm [0.394x0.394 inch]

Impact test in delivery condition

|

Key H=hardest W=softest |

S | mpact energy | Lateral expansion | Shear area | |||||||||||||||||||||||||||||||||

| Test no. | Plece no | Testing standard | Locatlon |

Temp. °F |

Charpy-V | ||||||||||||||||||||||||||||||||

| ft-Ibf | mils | % | |||||||||||||||||||||||||||||||||||

| 2228052-1 1 ASTME 23-18 L2 76 |

>=52 879191 |

>=15 384239 |

info 100100100 |

||||||||||||||||||||||||||||||||||

Hardness test indelivery condition(QTC)

The QTC is a prolongation of the final heat treated bar.

3×3 readings 120°apart are taken at 1/2 Radius(1/4T).

3×3 readings 120°apart aretakennear Surface.

1×3 readings aretaken in the center

The values statedare the mean values and,in parentheses,the single values.

Hardness test in delivery condition

| Test no. | Piece no. | Testing standard | Location | HRC | |||||||||||||||||||||||||||||||||

|

2228052-1 2228052-1 2228052-1 2228052-1 2228052-1 2228052-1 2228052-1 |

1 1 1 1 1 1 1 |

ASTME ASTME ASTME ASTME ASTME ASTME ASTME |

18-2201.05.2024 18-2201.05.2024 18-2201.05.2024 18-2201.05.2024 18-2201.05.2024 18-2201.05.2024 18-2201.05.2024 |

near Surface near Surface near Surface 1/2 Radius (1/4T) 1/2 Radius (1/4T) 1/2 Radius (1/4T) Center |

34-39 37.7 37.7 38.3 38 38 38.3 38 |

||||||||||||||||||||||||||||||||

Hardness test in delivery condition(Bars)

Location =near Surface

Hardness tests on bars are performed on cross-sectionsslices,taken from each bar

| Test no. Plece no Testing standard | HRC | ||||||||||||||||||||||||||||||||||||

| 34-39 | |||||||||||||||||||||||||||||||||||||

| 2228052-1 1 ASTME 18-2201.05.2024 | 37.7(373838) | ||||||||||||||||||||||||||||||||||||

| 2228052-1 2 ASTM E 18-2201.05.2024 | 37.7(373838) | ||||||||||||||||||||||||||||||||||||

| 2228052-1 3 ASTME 18-2201.05.2024 | 37.3(373738) | ||||||||||||||||||||||||||||||||||||

| 2228052-1 4 ASTM E 18-2201.05.2024 | 38.7 (383939) | ||||||||||||||||||||||||||||||||||||

| 2228052-1 5 ASTM E 18-2201.05.2024 | 39 (393939) | ||||||||||||||||||||||||||||||||||||

| 2228052-1 6 ASTME 18-2201.05.2024 | 38.3(383839) | ||||||||||||||||||||||||||||||||||||

| 2228052-1 7 ASTME 18-2201.05.2024 | 37.7(373838) | ||||||||||||||||||||||||||||||||||||

| 2228052-1 8 ASTME 18-2201.05.2024 | 37.3(373738) | ||||||||||||||||||||||||||||||||||||

| 2228052-1 9 ASTM E 18-2201.05.2024 | 38 (383838) | ||||||||||||||||||||||||||||||||||||

| 2228052-1 10 ASTM E 18-2201.05.2024 | 38.3(383839) | ||||||||||||||||||||||||||||||||||||

| 2228052-1 11 ASTME 18-2201.05.2024 | 38.3(383839) | ||||||||||||||||||||||||||||||||||||

Non-Destructive examination of inconel 718 round bars

Material identification test

Inspection quantity =100% of the bars

Uitrasonic examination of inconel 718 round bars

Inspection quantity =100%of the bars

"Inspection specification =ASTM A 388/A388M-19

Evaluation standard =API Specification 6A Twenty-first Edition Para 10.4.2.12.2&.3-PSL 4"

Inspection technique =Phased Array (straight-beam technique from the outside diameter)

Each bar is ultrasonically examined per NDE-31

The material fulfills the requirements

Surface examination

Inspection quantity =100%of the bars

"Inspection technique=Eddy -Current test(ET)

The material is without unacceptable surface defects"