17-4ph Forged Flat Bars For Steam Turbine Blades

These days, we produce some 17-4ph Forged Flat Bars For Gas Steam Turbine Blade for our mexico clients,

FOllowing is material inspection certificate of them

|

Quality Inspection Certificate acc. to EN10204-3.1 |

|||||||

|

Product Description |

Flat Bars |

Materal Grade |

17-4ph |

||||

|

CLients |

Central Termoelectrica Valle de Mexic |

Purchase Order # |

21991 |

||||

|

Melting Method |

EF++VOD+ESR |

Quantity |

22 |

||||

|

Heat # |

JLD240313-4 |

Forging Ratio |

10 |

||||

|

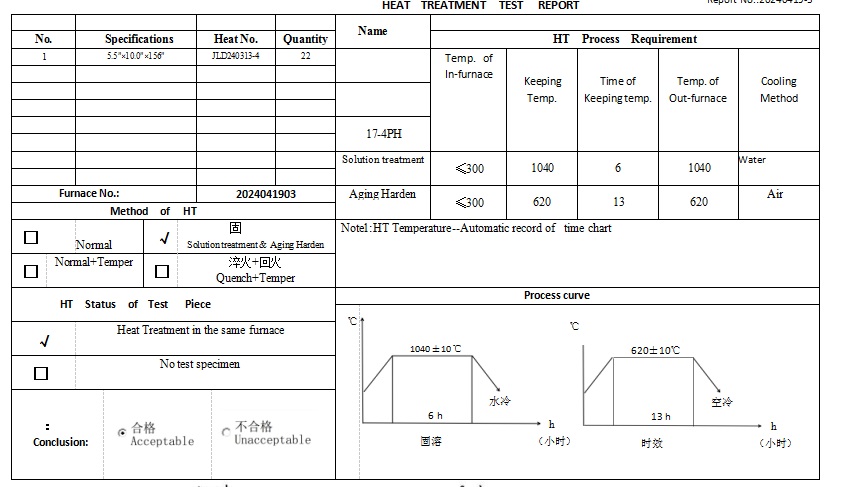

Heat Treat Lot # |

2024041903 |

Size (in) |

5.5 inch heighthess,10 Inch width,156inch length |

||||

|

Delivery Condition |

Forged,solution age harddening H1150,heat treatment, machined to bright surface |

Ferrite content:3% |

|||||

|

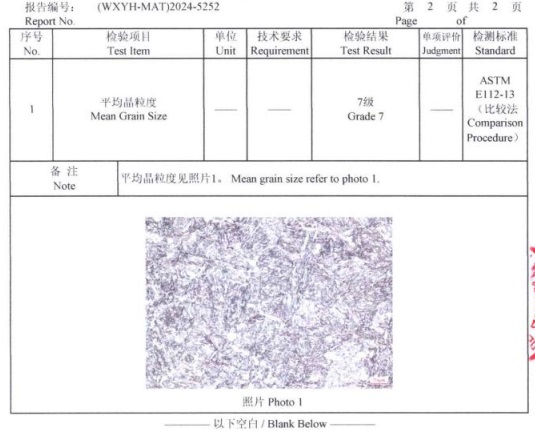

Grain size |

ASTM 7.5 |

Forging Identification Number: JLD240313-4 |

|||||

|

Material Specification |

ASTM A564, H1150 |

|

|

||||

Chemical compostion of 17-4ph forged turbine flat bars

|

Chemical Composition

per ASTM A751 |

|

C% |

Mn% |

Si% |

P% |

Fe% |

S% |

Cr% |

Cu% |

Nb%+Ta% |

Ni% |

|

Min |

|

|

|

|

balance |

|

15.0 |

3.0 |

0.15 |

3.0 |

|

|

Max |

0.07 |

1.0 |

1.0 |

0.040 |

0.03 |

17.5 |

5.0 |

0.45 |

5.0 |

||

|

Actual |

0.048 |

0632 |

0.671 |

0.027 |

balance |

0.001 |

15.32 |

3.12 |

0.193 |

4.4 |

Mechanical property test of 17-4ph forged turbine blades flat bars

|

Mechanical Properties

per ASTM A370 per ASTM E10 |

|

(YS) 0.2%Yield Strength (MPA) |

(TS) Tensile Strength (MPA) |

YS / TS Ratio(%)

|

Elongation

(%) |

Reduction of Area (%) |

Hardness (HBW) |

|

|

|

Surface of parts |

|||||||

|

Min |

725 |

930 |

|

16 |

50 |

|

277 |

|

|

Max |

|

|

|

|

|

|

|

|

|

Actual |

893 |

993 |

|

19.8 |

60 |

|

324 |

|

Following is heat treatment report of 17-4ph forged turbine blading steel flat bars

|

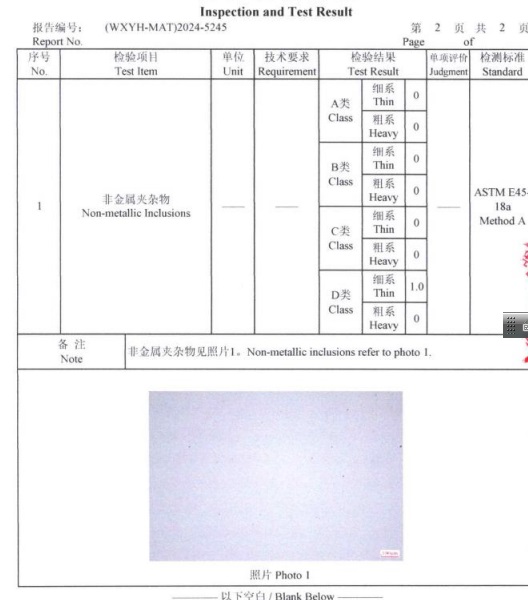

Non metallic inclusion test as per ASTM E45 by using method A |

A |

B |

C |

D |

||||

|

Max 3 |

Max 3 |

Max 3 |

Max 3 |

|||||

|

0 |

0 |

0 |

0 |

0 |

0 |

1.0 |

0 |

|

|

Charpy V- Notch Testing

per ASTM A370 |

QTC Size (in / mm) |

Test Temperature in room temperature |

|

|||||

|

10*10*55mm |

Min 41J |

|

||||||

|

Impact Test Value(J) |

157/157/150 |

|

||||||

|

NDE Test Results

Note: supporting NDE Reports to be provided! |

Method |

Standard |

Indications |

Results |

|

Ultrasonic Examination |

ASTM A388/388M-16a |

No |

Qualified |

|

|

Magnetic Particle Examination |

ASTM A275/275M |

No |

Qualified |

|

|

Visual Inspection |

|

There is no crack,seams,laps,shrinkage |

Qualified |

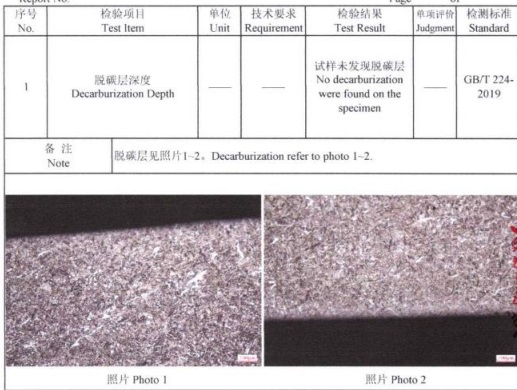

Following is Micro and Macro Examinations of 17-4ph forging turbine flat bars